Are you seeking an ideal approach to produce prototypes and miniatures for jewelry and dental applications? A resin 3D printing would be a perfect choice for you. They are in high demand for creating detailed and premium-quality models. You will get outstanding outcomes, but one of the challenging tasks is accurately estimating printing costs, which can be faced by both professionals and beginners.

Without the proper understanding of overall cost, you may undercharge your clients or overspend on purchasing materials and your energy. This is the point at which knowledge of total cost calculation becomes fundamental.

In this blog guide, we will help in understanding all the common factors that will affect resin 3D printing costs and how you can easily manage them using a 3D print cost calculator for further simplifying the procedure. Also, discover the best place from where you can purchase an authentic Reflex RS 3D Printer.

Key Factors That Affect Resin 3D Printing Costs

Here is the list of three main contributors to cost. Let us learn about each in detail as follows:

Cost of 3D Printer Printing Material

3D printer resin represents a significant portion of the operational cost in 3D printing. The price varies depending on the specific formulation, ranging from standard resins to specialized engineering materials. Typically sold in 1kg or 1-litre containers, the actual material consumption is determined strictly by the total volume of your print job. It is important to calculate the volume of both the model itself and the generated support structures. While supports are removed during post-processing, they are a necessary component for maintaining structural integrity during the printing process and should be factored in as a standard part of your material usage.

To save materials, we suggest you carefully estimate the resin usage before you start printing and try to avoid excessive support by making adjustments in your print orientation. For more details on consumables, read about 3D printer consumables resin vs fdm.

Printer Operational Costs

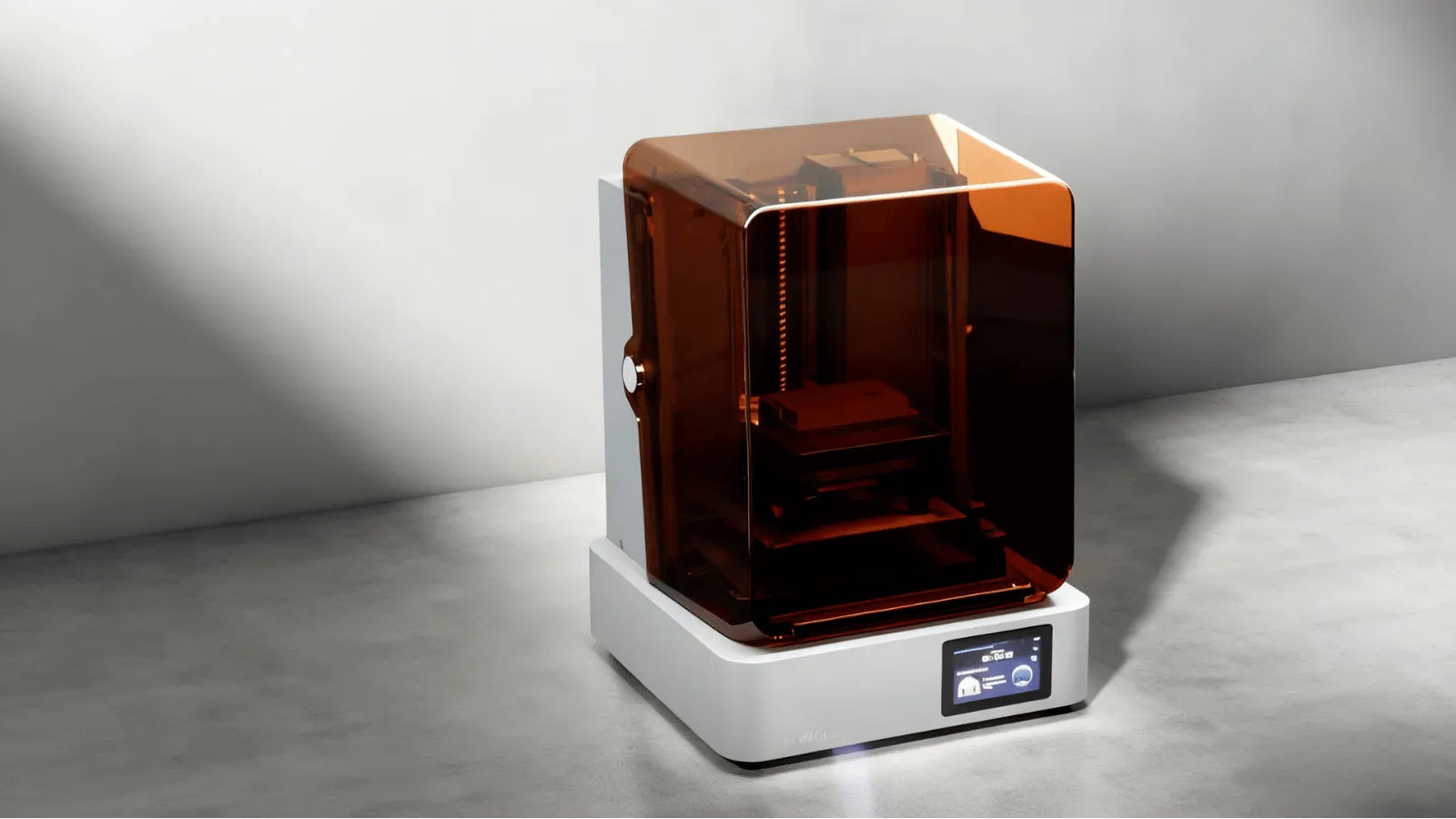

The 3D printer itself has a significant contribution to its cost per print. Its operational cost will include maintenance, machine depreciation, and consumption of energy. For instance, we recommend you try using a professional resin 3D printer from HeyGears' Reflex RS 3D Printer. This printer is known for providing speed and accuracy, which can easily save your time, and have a low cost on each print.

Keep this in mind, initially it might cost you more, but its print quality and efficiency will become economical with prolonged usage.

Print Time and Labour

The cost of each print completion is indirectly linked to the time. The longer the prints, the more energy they will consume for their completion, thus you will spend more time on their monitoring and post-processing. Plus, it will add extra labor cost, which includes model preparation, support removal, cleansing, and curing.

Calculating Resin 3D Print Costs: A Professional Approach

To accurately determine the ROI and unit cost of your production, you must look beyond simple material usage. Follow this comprehensive process:

1. Precise Material Estimation via Software

Don't guess. Use Blueprint Studio to generate an exact calculation of resin volume. Note that this figure must include both the model volume and the support volume.

-

Formula: Total Volume (ml) × Cost per ml = Material Cost

2. Comprehensive Energy Calculation

In a professional workflow, energy costs are not limited to the printer. You must calculate the total power draw of your entire production line.

-

Printer Draw: Professional resin printers typically consume between 120W and 200W.

-

Post-Processing Draw: You must also factor in the electricity used by Ultrasonic Cleaning Machines and UV Curing Units.

-

Formula: (Printer Wattage × Print Hours) + (Wash/Cure Wattage × Cycle Hours) × Electricity Rate = Total Energy Cost

3. Consumables and Maintenance

In high-frequency production, consumables are a significant expense often overlooked by hobbyist calculators. You must account for:

-

Fluids: High-volume usage of Isopropyl Alcohol (IPA) or specialized ultrasonic cleaning fluids.

-

Disposables: Nitrile gloves, lint-free paper towels, and resin filters.

-

Wear & Tear: Periodic replacement of release films (FEP/NFEP), LCD screens, and UV curing lamps.

4. The Hidden Cost: Labour

For business applications, human time is often the most expensive variable. Calculate the time spent on file preparation, washing, support removal, and surface finishing.

5. The Professional Cost Formula

Combine these variables into a unified cost model. We recommend adding a buffer for potential print failures.

Total Cost =(Material+Energy+ Consumables + Labor + Machine Depreciation)

6. Leveraging Blueprint Studio for Data

Instead of relying on generic online calculators that use estimated averages, utilize the data directly from Blueprint Studio. The software provides the precise print time and total resin volume (including supports) for your specific project. You can input these exact metrics into your internal cost spreadsheet to calculate the true cost per unit with high accuracy.

Overview of Available Tools

This calculator will help you estimate the overall cost of the printing process. You need to add all the basic information, and instantly you will get the results.

How to Use a Cost Calculator Effectively

To get the precise results, you need to enter the mentioned details correctly:

-

Accurate cost of resin per litre.

-

Your model's printing time and volume.

-

Labour time per hour and local electricity rate.

-

Additional things include gloves, alcohol, support, etc.

So now, when you have successfully entered all the details, your 3D print cost calculator will provide you with an estimated cost per print that might help you in making adjustments to your expected budget rate.

Tips for Reducing Resin 3D Printing Costs

Here's how to save money:

-

Optimizing Print Settings

To effectively balance quality and cost, start by optimizing your model design. Techniques such as hollowing parts and adding drain holes are the most effective ways to significantly reduce resin volume. Beyond design, the printing parameters (such as exposure and lift speed) play a vital role in success. However, manual tuning is often time-consuming. Instead of struggling with trial-and-error, we recommend choosing a 3D printer brand that offers preset resin parameters. An integrated ecosystem—where the printer, software, and materials are tuned together—eliminates the need for manual calibration. This streamlined approach paves the way for professional-grade reliability, a standard found in advanced systems like the HeyGears RS.

-

Bulk Resin Purchasing and Discounts

Purchase resin in bulk or during sales to reduce the cost per litre. If you print frequently, this is an easy way to save money.

-

Maximizing Printer Efficiency

For quicker, less wasteful production, use effective printers like the Reflex RS 3D Printer. Additionally, routine calibration and maintenance prolong the life of your printer and lower repair costs.

Common Pitfalls in Estimating Resin 3D Printing Costs

Sometimes, professional users still make the mistake of miscalculating their expenses. Here are some common pitfalls that should be avoided to calculate an accurate resin 3D printing cost.

Overlooking Hidden Costs

Always look for hidden costs, such as gloves, alcohol, resin storage boxes, or filters, because over a specific period of time, these items, when added up, will have a drastic effect on your overall profit margin, especially if you are a business owner. For a list of required supplies, see our essential 3D printing tools guide.

Miscalculating Print Volume

Your cost estimates may be invalid if you estimate resin usage incorrectly. Include supports in your volume calculation and always rely on the estimates provided by your slicing software.

Underestimating post-processing

The time and materials required for the cleaning, curing, and finishing processes cannot be disregarded. A realistic total cost per print is ensured by appropriately accounting for them.

Conclusion

In the end, we can conclude that you might find it difficult at the start to calculate the overall cost of resin 3D printing. But when you gain a better understanding of its main components, it will become easier for you to accurately plan your budget. We suggest you try using a 3D print cost calculator, which will instantly simplify your process, thus helping you in making better-informed decisions that can be used for professional and personal projects.

At HeyGears, we offer the Reflex RS 3D Printer, engineered to deliver professional precision and consistent reliability. By integrating with our pre-calibrated ecosystem, it removes the variables that often lead to print failures. Instead of worrying about wasted time on failed attempts, you can rely on the Reflex RS to produce expert-level results from the start. Ready to transform your workflow with industrial-grade stability?

Share:

Unlock Precision with HeyGears' Black Friday 3D Printing Deals

Common Resin 3D Printing Issues and How to Prevent Them