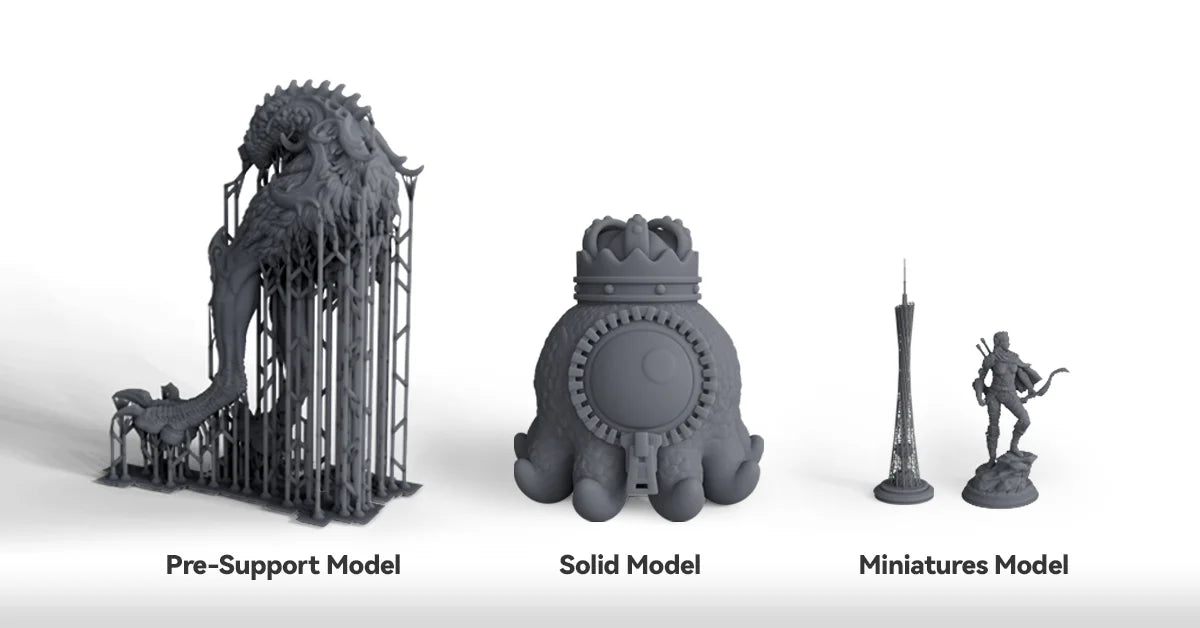

Figurines & Creatures

10-28 mm model

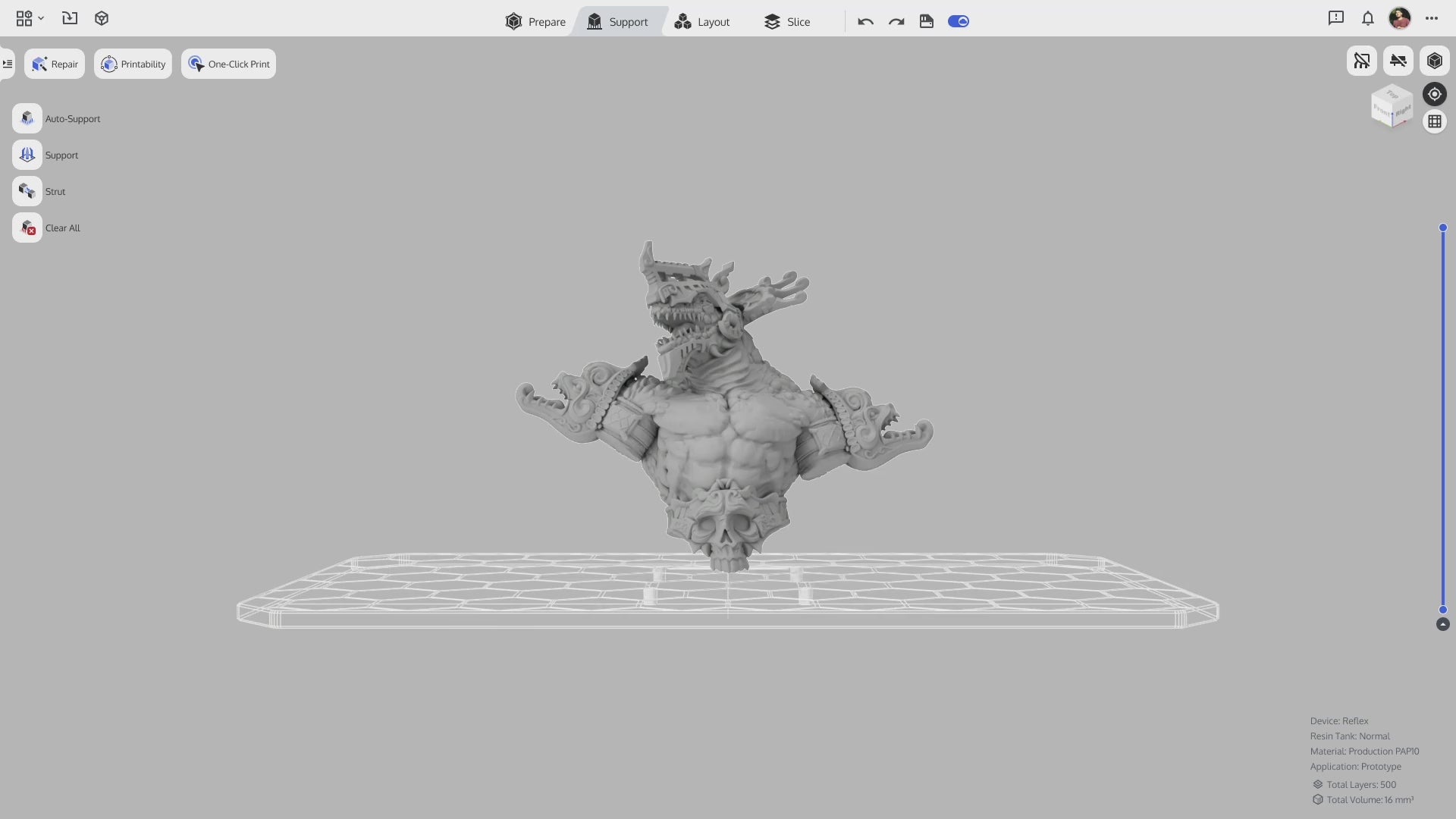

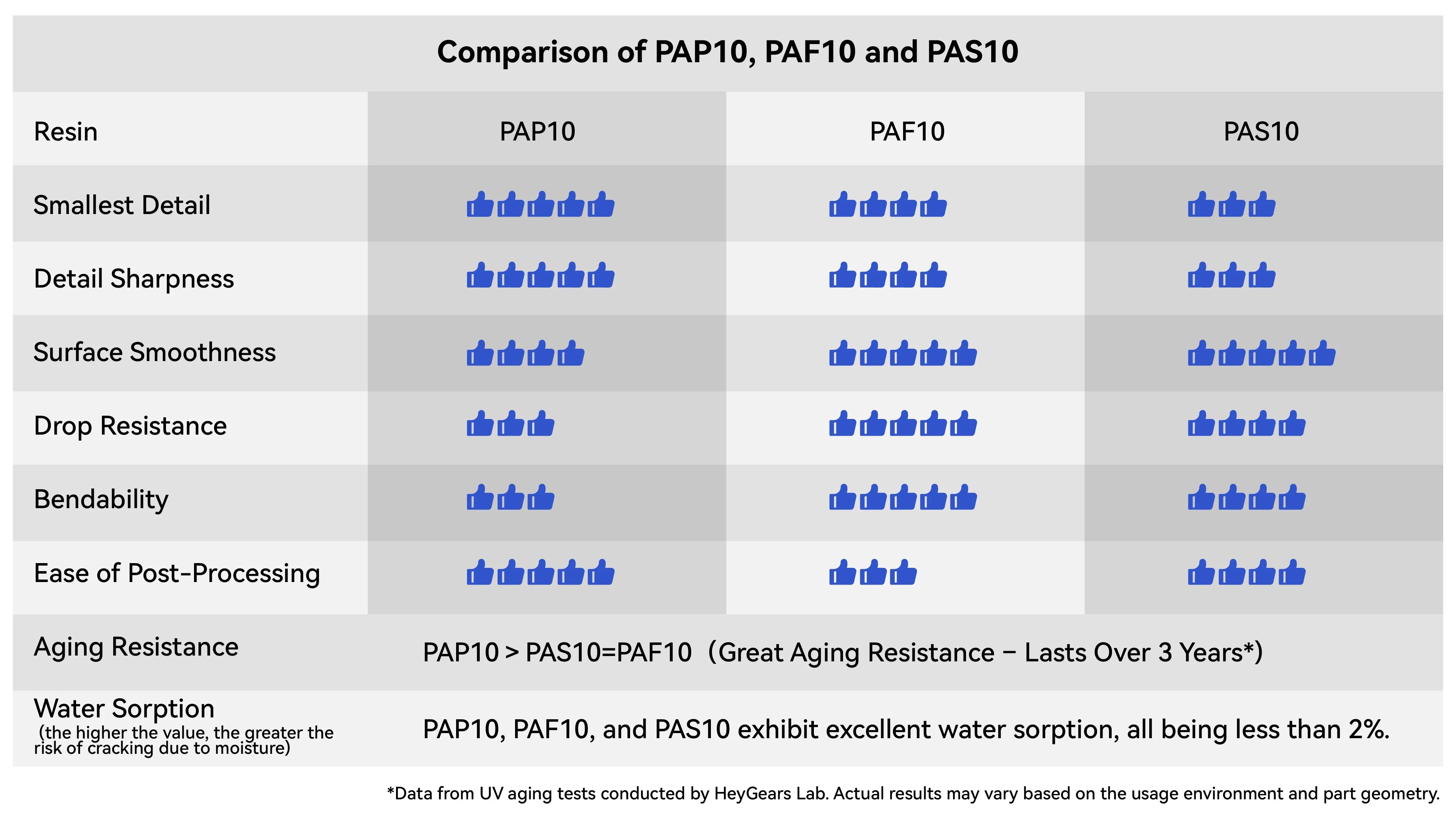

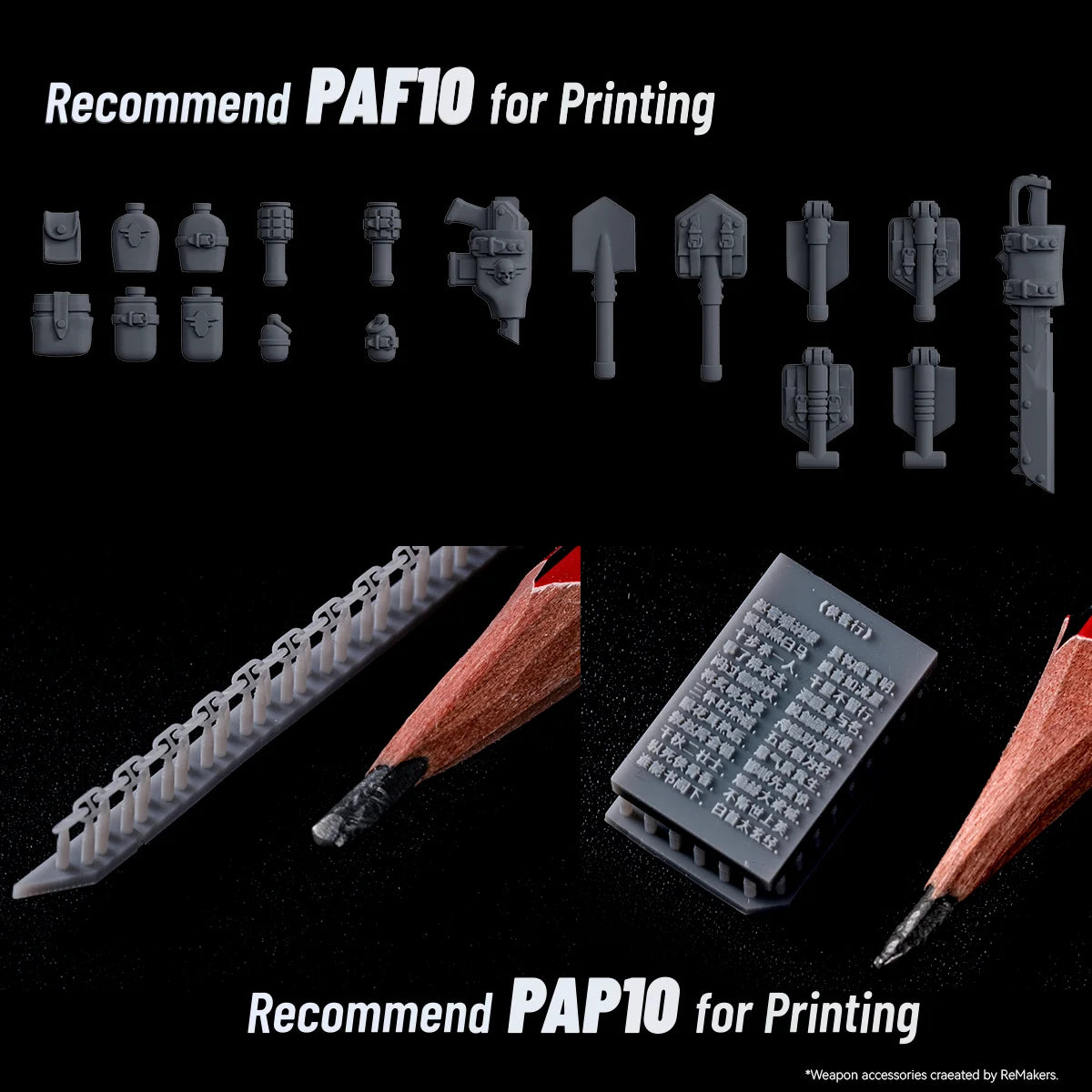

Miniatures ranging from 10 to 28 mm in height often necessitate ultra-fine detail 3D printing, even approaching near-microscopic detail capabilities. Therefore, the resin used needs to have the ability to 3D print ultra-fine details and feature smaller support points to minimize the likelihood of defects in the surface of the model.Recommend PAP10 for Ultra-Fine Printing.

Above 54 mm

For miniature models over 54 mm in height, it is essential to consider the balance between cost-effectiveness and surface quality:

1. For detailed models with delicate parts requiring break-resistance, use PAF10.

2. For smooth surfaces without intricate structures, opt for the more cost-effective PAS10.

Terrain

This type of model generally does not demand excessive detail sharpness. The models typically feature a smoother surface and are easy to paint. However, due to their larger size and the substantial amount of resin consumed, we recommend the more cost-effective PAS10.

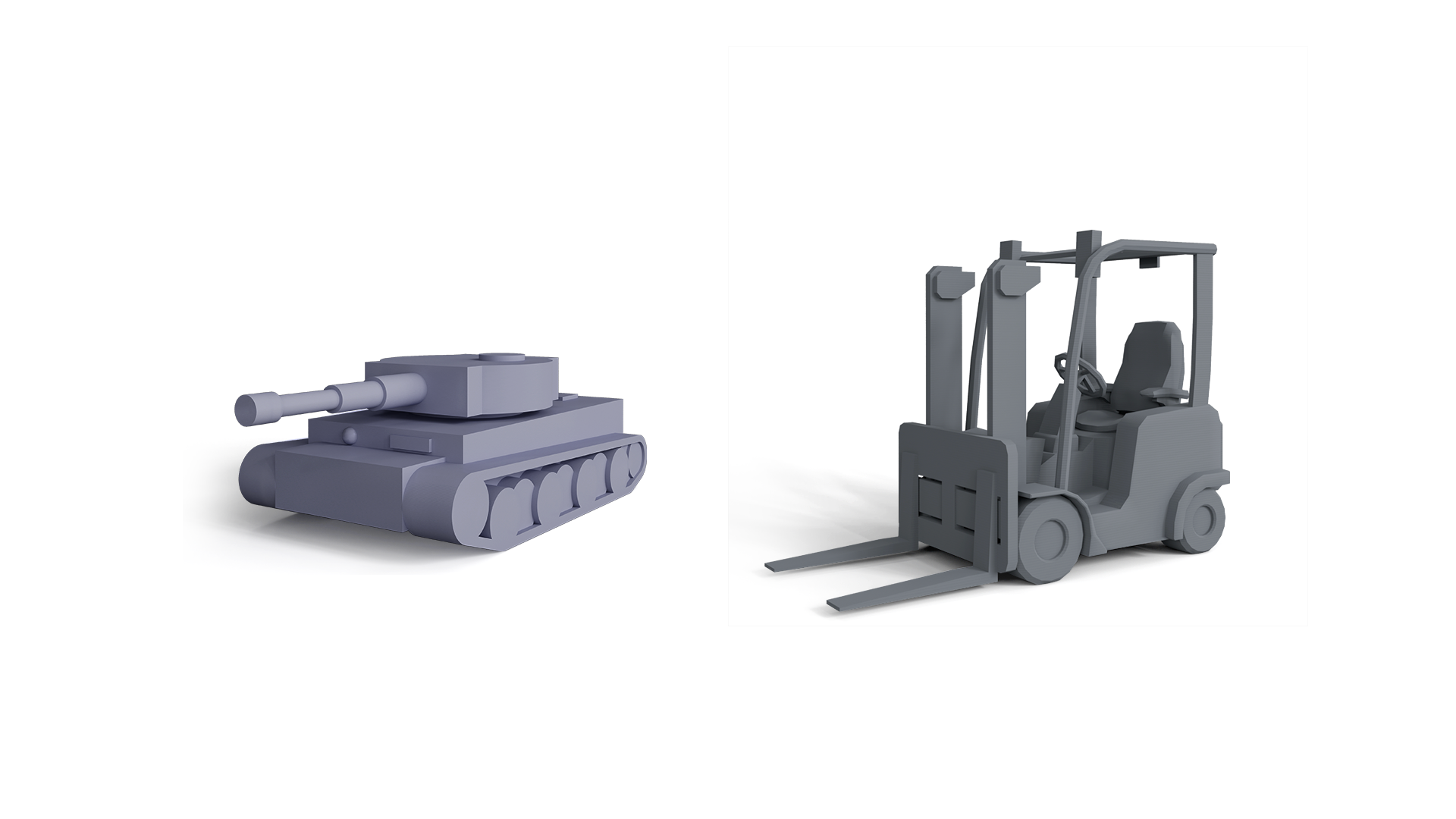

Vehicles & Machines

1. PAS10 is recommended for most vehicle models that are large in size and have a smooth surface.

2. For vehicle models with complex structures that require greater break-resistance, PAF10 is recommended.

Accessories

1. For accessories such as weapons or limbs that demand both intricate detail and a certain degree of break-resistance, PAF10 is recommended.

2. If the accessories are small in size and have intricate details, PAP10 is recommended.

UltraPrint Production PAF10 Flexible Production Resin (PVC-like)

UltraPrint-Production PAP10 Precise Detail Resin