3D printing or additive manufacturing is coming back in multiple ways to change the healthcare, aerospace, and even the home design industry.

The newcomers normally pose the following question: How does a 3D printer work step by step? Having the answer would avoid mistakes in case you choose to get your resin machine or any other model.

In this article, we’d describe what 3D printing is, take you through the entire process of turning a sketch into a completed solid part, tell you the broad categories of printers you can purchase, and demonstrate why 3D printers are the first choice when you want fine detail and excellent finish.

What Is 3D Printing?

3D printing is a new methodology of making objects; this is executed by using thin sheets of material that are layered in each other until an item forms.

This is unlike the traditional carving, cutting, or drilling out of excess stock: instead, it uses only the required material, obviating waste and introducing the possibility of shapes that otherwise would prove very difficult to complete.

It begins with a digital 3D blueprint typically generated on simple-to-use CAD software. After the design is complete, a slicing software will divide that blueprint into hundreds or thousands of thin slices, and convert it into a printer-friendly code, such as G-code for FDM 3D printing.

Then the printer starts doing its work, be it melting filament, curing liquid resin, or just blasting the powder with lasers, each layer on top of the previous one, until the whole object is complete.

From rapid prototyping and custom gifts to airplane parts and even medical models, people like 3D printing since things are fast, tailored to each need, and can be initiated with low-cost printers.

Types of 3D Printers and Technologies

To have a better understanding of how a 3D printer works step by step, you must examine the various print methods available. These are the most popular ones that you will encounter:

FDM (Fused Deposition Modeling)

Works with coils of plastic filament.

The plastic is melted with a hot nozzle that pulls the plastic in a layer by layer.

Ideal for tough parts, quick prototypes, and fun weekend builds.

SLA (Stereolithography) and LCD Resin 3D Printers

Begins with a liquid resin that cures with the use of a UV light, one layer at a time.

Adds more detail and an almost glass finish.

It is great for printing jewelry, intricate miniature models, and prototyping parts for engineering purposes.

In case you need high precision resin printing, consider HeyGears best resin 3D printers, which have the top selection of printers that fit experts and beginners.

SLS (Selective Laser Sintering)

Operates with powdery material, mainly nylon.

Every layer is melted and connected by a laser.

Excellent selection when it comes to industrial components, functional prototyping, and low-volume manufacturing.

Each type of printing technique excels in various conditions. However, at the points where detail and smoothness count most, resin machines tend to take the lead. Take a look at the latest resin 3D printers.

Advantages and Disadvantages of 3D Printing

It is important to understand the advantages and the disadvantages before proceeding to how a 3D printer works step by step.

Advantages

Customization: Each print may be an individual one at no additional cost.

Reduced Waste: It uses only the necessary material.

Rapid Prototyping: Build up models in a couple of hours.

Complex Geometries: Shapes that cannot be done with conventional design.

Disadvantages

Speed: Time-consuming parts that are larger or more complex can require hours or several days.

Post-Processing: Resin prints have to be cleaned and cured.

Material Limitations: Plastics, resins, and certain metals only.

Durability: Not every component of 3D printing is as tough as injection-molded equivalents.

Nevertheless, given the proper materials, such as high-quality 3D printer resin, you may produce top-notch results even with functional purposes.

The Working Principles of 3D Printing

Then, how does a 3D printer work successively? Let us simplify it into simple steps:

1. Design the Model

Begin by either designing (or downloading) a 3D model file using a 3D modeling software (typically in the STL or OBJ file formats). You can use CAD software that is free, such as Tinkercad, or more advanced, such as Fusion 360.

2. Slice the Model

Slice the 3D model using slicing software (e.g., Cura or Chitubox) into slices that are placed horizontally. This kind of software will convert the 3D model into the instructions that your printer will follow.

3. Prepare the Printer

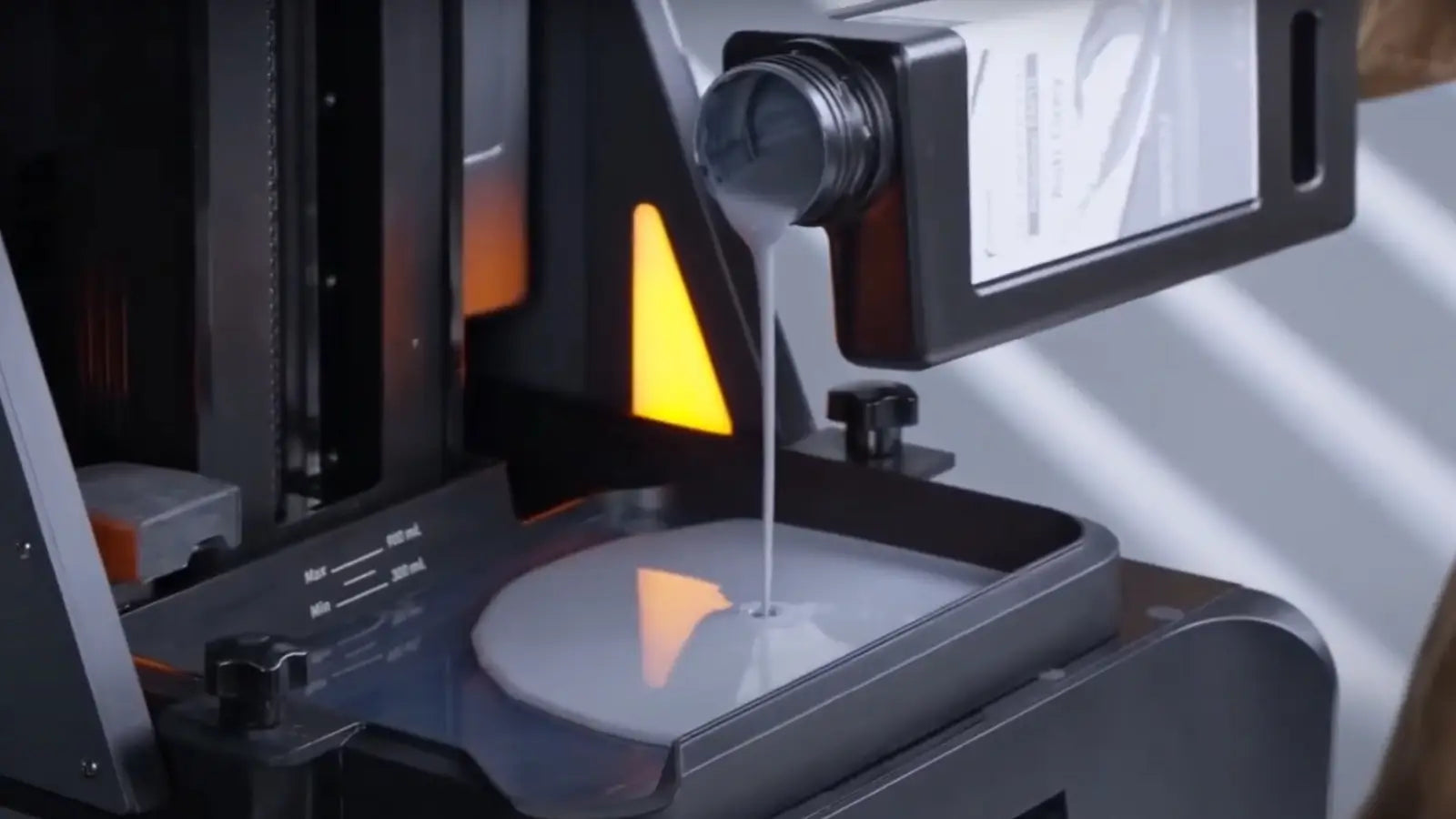

Install your printer depending on its type. In FDM, put in the filament, get bed leveled, nozzle preheated. With resin printers, the 3D printer resin must be poured, the build plate set level, and the UV exposure conditions verified to guarantee proper curing.

4. Start the Print

Transfer your sliced G-code file through USB, SD card, or Wi-Fi. The printer will start to print layers at a time. FDM uses melted filament to print out, and the resin printers use UV light to harden the liquid resin into solid layers.

5. Post-Processing

After printing, take off supports and, where needed, sand FDM prints. Hardening of resin prints will need rinsing in isopropyl alcohol and followed up with UV light to make the prints more durable.

When this is done, your object is ready. That is how a 3D printer works step by step through the stages of a digital file to a physical something.

Real-World Applications of 3D Printing

The question of how a 3D printer works step by step is not only academic, but it is changing industries:

Medical

Hearing aids, dental aligners, and prosthetics already come in 3D-printed form. Resin 3D printers are particularly helpful in printing dental molds and surgical models.

Education

With 3D printers, students are capable of developing prototypes of various projects, constructing models, and experiencing manual learning in classrooms.

Manufacturing

Small-batch parts and fixtures, and rapid tooling can be produced to order, thereby saving time and cost.

Art and Jewelry

With the help of smooth finishes, the resin 3D printers are used to print custom jewelry, miniatures, and design sculptures.

Whether you have an interest in any of these spheres, HeyGears is one of the places to find the best models of resin 3D printers and accessories.

Conclusion

So, how does a 3D printer work step by step? Digital design, post-processing, and model slicing are fueled by different technologies, such as an FDM one or resin-based curing. During your discovery of 3D printing, the steps, tools, and applications come in handy to make you successful sooner.

No matter what you are printing, process parts, miniatures, or prototype parts, the tool selection is important.

To get the best high-resolution outcomes available, take a look at HeyGears best resin 3D printer, browse HeyGears resin 3D printer collection, and buy 3D printer resin to get started printing now.

Related articles:

How to Improve 3D Print Quality

Share:

3D Print File Formats Explained: Which One Should You Use?

10 Best Things to Print on a 3D Printer in 2025 for Beginners