For a 3D printing enthusiast, there is nothing more frustrating than slicing a model, hitting print, and then seeing your printer start to extrude plastic way off the center of the build platform. You want accuracy, but your object impacts a corner, perhaps even partly overhanging the build plate. Sound familiar?

One very common problem that occurs when 3D printing is that it does not begin in the center. The good news? It's seldom a hardware failure and almost always a configuration problem, which is a good thing. If 3D prints are not printing in the center, here's what to do.

Common Symptoms of Off-Center FDM Prints

It is especially nebulous when you can tell something is off, and it’s reasonably clear print isn’t where it should be. But what exactly should you be on the lookout for?

- Prints starting from a corner or edge: The nozzle does not start in the center, and instead is way off-center while laying down filament.

- Models that are out of whack or couple off: The object is being printed on the bed, but it is also partly printed in mid-air or overhangs the model.

- A more challenging one, bed adhesion: If a print starts too close to the edge, it frequently won’t stick well.

- Problems with plotter preview to print: The model seems properly centered in the slicer preview, but in the end, the physical print is not aligned.

And if you can catch these symptoms early, you can act where it matters before you waste a lot of time and filament.

Cause Analysis and Quick Fixes

Off-kilter printing may stem from several software or hardware culprits. It also tends to be a result of the way the slicer and the printer interpret the commands or how the physical position is started. Let’s break it down.

Incorrect Bed Size or Origin in Slicer

Your slicer software controls how your printer translates a digital 3D model into movement instructions. If the bed size or origin position in your slicer doesn't match the physical setup of your printer, your print won’t be placed correctly.

Quick Fix:

- Launch your slicer program (Cura, PrusaSlicer, Simplify3D).

- Access the printer settings and verify that the bed size is consistent with the dimensions of the printer you own.

- Check origin: Some printers use the front-left corner as the origin point (0,0), others the center.

- Click ‘Center’ or ‘Arrange’ (depends on which slice tool you are using) in the slicer software to re-center the model before slicing.

Home-Position Calibration Problems

The “home” position is a base reference your printer uses to understand its coordinate system. If the endstop position is off, or worse, the printer isn’t correctly calibrated for it that the print will be off right off the bat – from the first move!

Quick Fix:

- The control panel or the command G28 to home all axes.

- Look at where the nozzle homes: does it meet the limit switches nicely?

- Ensure the bed is square and endstops are held tight.

- If possible, tune offsets in the firmware or in the EEPROM.

G-code Generation Errors

Sometimes, it's in the G-code file itself. If your slicer did a poor job of generating gcode because of wonky settings or a crappy profile, your printer is still going to do exactly what it was told, right or wrong.

Quick Fix:

- Reslice the 3D model with good printer settings.

- Load the G-code file into a G-code viewer (or similar) and see if the model is in the center.

- Never use old-style slicer profiles – always make a new one for a new build.

- If it still doesn't work and you have something else strange going on, clear the slicer cache.

Firmware Configuration Mismatch

Firmware is the printer’s internal “brain.” If it doesn’t match your slicer settings it can cause misalignment.

Quick Fix:

- Access the firmware settings via your printer’s screen or configuration files.

- Compare to your slicer’s values.

- Upgrade your firmware, or reset your default to reflash if necessary.

Other Contributing Factors

In some cases, it’s not just about slicer or firmware issues. Physical or environmental problems can also cause a model to print off-center.

Here are a few less obvious causes:

- Loose belts or pulleys: These affect the axis movement

-

Obstructed axis movement: Cables, dust, or debris can block the print head from moving freely.

-

Offset nozzle configuration: Especially in dual extruder systems, the active extruder may not be centered.

-

Corrupted SD card or USB drive: Can contain damaged files, causing unpredictable behavior.

Take a few minutes to inspect your printer and run a basic test print after any changes.

How to Avoid Crooked Prints in the Future?

Getting your printer to play nice is all well and good, but we’ve also got to make sure it stays playing nice.

Here are a few things you can do:

- Standardize slicer profiles: Save a working profile that is known to be good.

- Mark your SD cards: Never use a card that hasn't worked before.

- Ensure firmware and slicer are always up to date: Often, bug fixes resolve positional problems.

- Periodically recalibrate: Particularly after relocating your printer or replacing hardware.

- Keep a track of your working settings: Take screenshots of the slicer and firmware configuration so you can always refer back.

A well-maintained printer is a consistent printer.

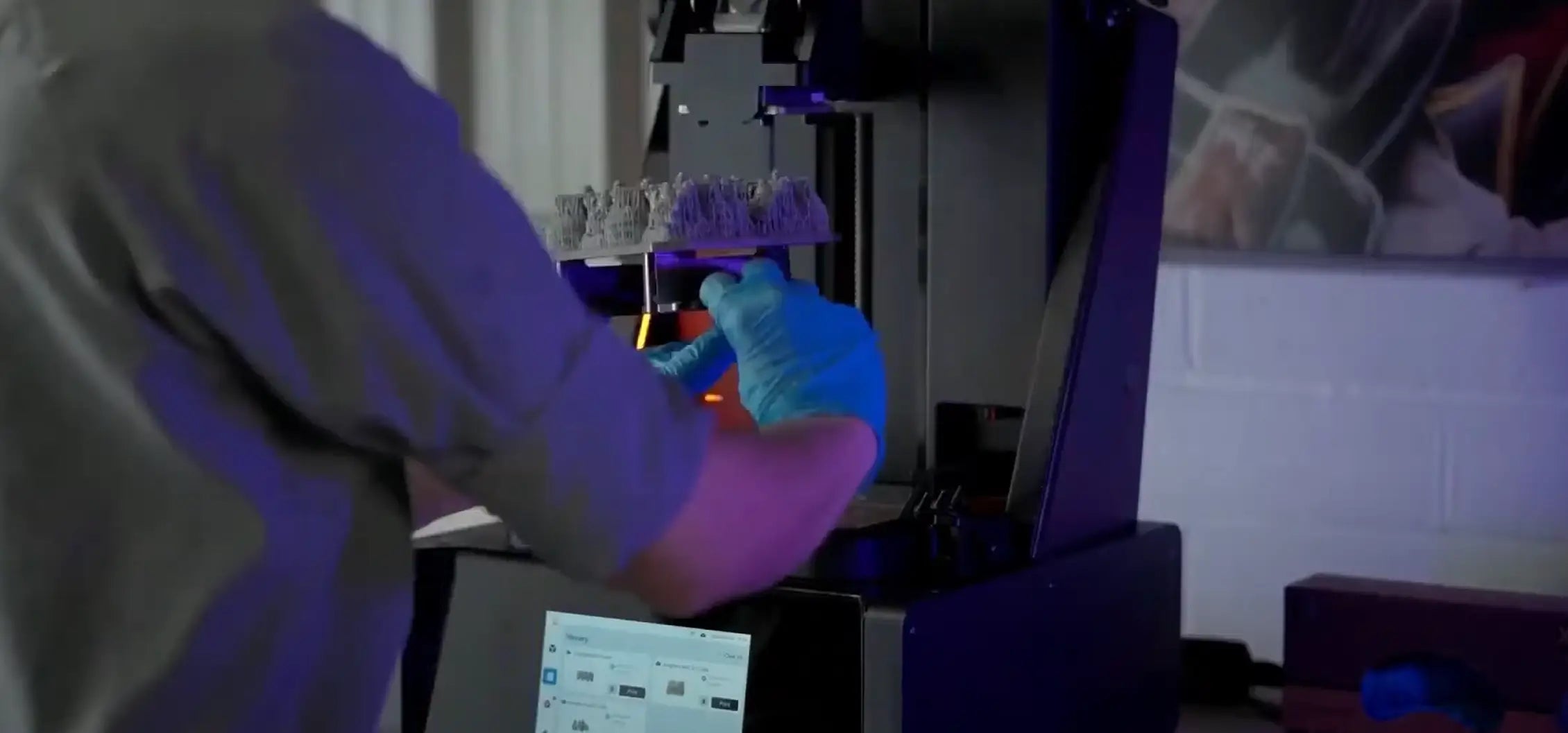

Do Resin 3D Printers Have the Same Issue?

Resin 3D printers (like SLA or DLP models) use an entirely different printing process. They rely on a projector or screen to cure UV resin layer by layer, rather than moving a nozzle across a bed. Because of this, they’re much less likely to suffer from off-center prints.

That said, incorrect model placement in the slicer or an unlevel build plate can still cause misalignments. But the frequency and severity of off-center issues are significantly reduced.

If you're looking to explore this cleaner and more precise form of 3D printing, consider investing in a Resin 3D Printer. Brands like HeyGears offer a range of options for professionals and hobbyists alike.

You will get the best Resin 3D Printers that deliver excellent precision, smooth finishes, and more reliable positioning than many FDM printers.

To get the best results, don’t forget to pair your resin printer with high-quality UV-cure resin and a professional curing machine.

Conclusion

3D printing is an amazing blend of art and engineering. Fortunately, off-center prints are one of the easiest issues to fix, once you understand where to look.

Start with slicer settings. Move on to homing and calibration. Then inspect your firmware and hardware. Take your time with each step.

And if you’re ready to explore more consistent and high-resolution printing, try best quality printers from Hey gears.

Websites for Free 3D Printing STL Files

Share:

Why Your File Failed to Be Recognized by a Resin Printer

Best 3D Printer for Beginners