Dear creators with ingenious ideas and passionate jewelry enthusiasts, I'm sure you all have had such a moment: a jewelry design with extremely intricate details is sketched in your mind. Today, 3D resin printing technology has not undergone significant innovation. Complex structures that used to take weeks or even months to carve can now be rapidly formed with astonishing precision. This 2025 3D printed jewelry guide is a tailor-made "treasure hunt map" for you who are eager to embark on the journey of a digital goldsmith. Next, we will jointly uncover the unique charm of 3D printed jewelry machines.

The Digital Shift: From Old-School Craft to Cutting-Edge Tech

For generations, crafting exquisite jewelry was a truly labour-intensive, expensive, and often slow process. Imagine meticulous hand-carving wax models, sketching designs, and creating prototypes and moulds by hand – it required immense skill and dedication. These traditional methods, while beautiful, often meant limited creativity, higher costs, and longer lead times.

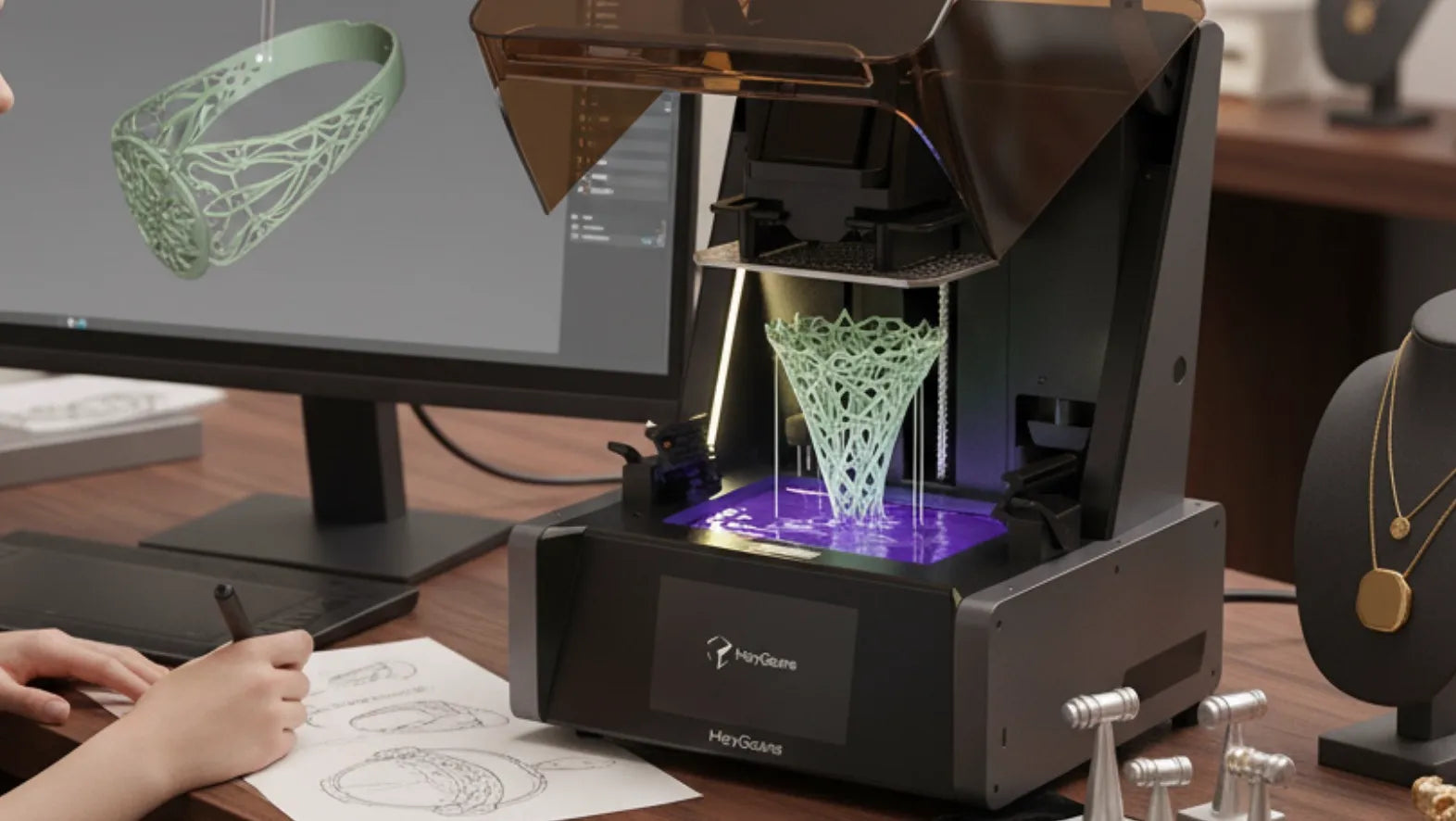

But guess what? 3D printing has disrupted this landscape entirely, creating a seamless bridge between digital design and stunning physical pieces. This "digital goldsmith" shift is all about combining the precision of technology with the timeless art of jewelry making. It ushers in unmatched design freedom, super-fast prototyping, and cost-effective customization, literally opening up the industry to everyone from passionate hobbyists to seasoned professionals.

Why Resin 3D Printers are a Jeweller's Best Friend

When we talk about 3D printing for jewelry, we're almost always talking about resin 3D printers. Why are they so indispensable?

It boils down to two key factors:

Unmatched Precision and Intricate Detailing

Imagine creating tiny filigree, crisp lettering, or perfectly precise stone settings. Resin printers deliver razor-sharp precision, often with details up to 20 microns, which is crucial for the delicate features jewelry demands.

Enhanced Design Flexibility and Creative Freedom

These machines let you create complex organic shapes, hollowed designs, twisty rings, and details that would be incredibly difficult, if not impossible, to achieve by hand. Your imagination truly becomes the only limit!

Key Features for Your Ideal Jewelry 3D Printer

Choosing the right printer feels a bit like picking a new power tool – you need the right one for the job! Here’s what to look for:

Paramount Resolution for Flawless Jewellery Prints

This is perhaps the most critical factor. For intricate jewelry, you need a printer that can resolve tiny details. Look for printers with high resolution settings, capable of producing details as fine as 35–50 microns or even 8 µm for ultra-fine wax patterns. Lower resolutions will result in blurry or 'blobby' details, which we definitely don't want on our precious creations!

Essential Material Compatibility for Diverse Jewellery Applications

Your printer needs to work well with different types of resins. We'll chat more about resins in a moment, but ensure your chosen machine can handle castable resins, prototyping resins, and even those for rubber moulding.

Optimizing Build Volume for Your Production Needs

Think about how much you'll be printing. If you're a hobbyist, a smaller build volume is fine. But if you're planning to create larger pieces or produce batches, you'll want a printer with a build volume that matches your ambition.

Speed, Ease of Use, and Workflow Efficiency: Time is money, right?

DLP (Digital Light Processing) printers use a projector to cure entire layers at once, making them incredibly fast, especially for batch production. They offer fantastic precision, and their projectors have a long lifespan (20,000+ hours).

MSLA/LCD (Masked SLA) printers like HeyGears Reflex RS 3D Printer use an LCD screen and UV LEDs, offering great speed and affordability, making them a popular entry-level choice. Just remember that the LCD screen is a consumable part with a shorter lifespan (~2,000 hours).

SLA (Stereolithography) printers use a laser to trace layers. Historically, they were known for super smooth surfaces, and modern versions are still excellent.

Think about how easy the printer is to set up and operate. Look for intuitive interfaces and clear instructions.

Seamless Software Compatibility and Robust Support for Jewellery Design: Your printer needs to "talk" nicely to your design software. Whether you use TinkerCAD, Blender, RhinoGold, 3Design, MatrixGold, or ZBrush, ensure your printer's software (the "slicer") can easily import your files. Also, good customer support and an active user community can be lifesavers!

Advanced Printer Calibration and Maintenance: This might sound a bit technical, but it's key for consistent quality and extending your printer's life. Learn about Z-axis calibration (super important for resin printers!), exposure calibration for new resins, and regularly inspecting/replacing your FEP film. A little care goes a long way in preventing failed prints!

The "Ecosystem" of a Chosen Printer: Don't just look at the printer itself! Consider the whole package: the quality of compatible resins (are they reliable?), the slicing software (is it user-friendly and powerful?), the customer support and warranty, and the availability of spare parts. A great ecosystem (like what Formlabs is known for) can make your life much, much easier.

Choosing the Right Resins for Jewellery Production

Just like you wouldn't use any metal for a fine piece of jewelry, you can't use just any resin. The right 3D printing resin is paramount!

Castable Resins for Lost Wax Casting

This is where the magic truly happens for metal jewelry! Castable resins are designed to burn out completely and cleanly in the kiln, leaving absolutely no ash residue. This is crucial for avoiding defects in your final metal piece. They also need to have low shrinkage for dimensional accuracy (especially important for stone settings!) and maintain sharp details.

Resins for Prototyping and Custom Jewellery Designs

Sometimes, you just need a quick, affordable print to test your design, size, or appearance. These resins are usually less expensive and perfect for iterating on your ideas.

Resins for Rubber Moulding in Jewellery Making

Some jewellers use 3D prints to create masters for rubber moulds, which can then be used for traditional wax injection. Specific resins are formulated to hold up well for this process.

The Efficient Workflow of 3D Printing in Jewellery Manufacturing

Ready to see how it all comes together? Here's the typical workflow, moving from a digital idea to a beautiful piece of jewelry:

From Digital Design to Physical Jewellery Model

It all kicks off in CAD (Computer-Aided Design) software. This is where you digitally sculpt your design. Tools like Rhino, Blender, RhinoGold, MatrixGold, 3Design, or ZBrush are popular choices, allowing for everything from precise measurements to intricate organic forms. You can even design in one program (e.g., ZBrush for sculpting) and refine in another (like MatrixGold for stone settings).

Essential Post-Processing Techniques for Jewellery Prints

Once your resin model is printed, it's not quite ready! This step is crucial and mandatory. You'll need to:

Wash the 3D resin print in a solvent (typically Isopropyl Alcohol - IPA) to remove any uncured liquid resin. Skipping this leaves prints sticky or gooey!

Then, UV-cure the print to fully harden it and achieve maximum strength and stability. A dedicated Wash and Cure Station is a fantastic investment here.

Finally, carefully remove any support structures and smooth out any tiny imperfections. The goal is a flawless surface before it goes to casting!

Integrating with Lost Wax Casting (Investment Casting)

For metal jewelry, this is the professional standard. Your beautiful resin print acts just like a traditional wax model:

The print is attached to a "casting tree" alongside other pieces.

This tree is then placed inside a metal flask and surrounded by investment plaster.

Once the plaster hardens, the flask goes into a kiln, where the resin pattern is burned out completely, leaving a perfect cavity.

Molten metal (gold, silver, platinum, etc.) is then poured into this cavity.

After cooling, the metal pieces are removed, separated, polished, and finished with any stone settings.

Expert Tips for Flawless Prints and Optimal Results

Here are some nuggets of wisdom from the pros to help you achieve stunning results every time:

Design for Success

Wall Thickness is Crucial: For delicate resin prints, aim for at least 0.4–0.6 mm wall thickness to prevent breakage. If you're experimenting with FDM for plastic fashion jewelry, go even thicker!

High Resolution for Detail: Always use your printer's highest resolution settings for jewelry – those 35-50 microns are your friends! This prevents details from looking blurry or melted.

Resin Handling & Post-Processing Mastery

Resin Exposure is Key: Be precise with your UV light exposure! Too much makes prints brittle; too little leaves them soft or droopy. Always check your resin's specific profile and the manufacturer's guidelines.

Post-Processing is Non-Negotiable: As we discussed, washing and UV curing are vital. They aren't just extra steps; they are what make your prints strong, stable, and ready for the next stage.

Choosing the Right Resin: Remember, for casting, focus on resins that guarantee a clean, ash-free burnout and low shrinkage. These properties are the foundation of a successful metal casting.

Practical Advice for Getting Started and Sustaining Growth

The great news is that getting into 3D printing for jewelry is more accessible than ever!

-

Starting Without Breaking the Bank: You absolutely don't need to spend a fortune to begin. You can:

-

Design your pieces using free CAD software like TinkerCAD or Blender.

-

Print prototypes at home on an affordable resin printer (many great MSLA options exist!).

-

Outsource the final metal casting to a local jeweller or a specialized service. This gives you full creative control without the huge upfront cost of industrial casting equipment.

-

Essential Gear Beyond the Printer:

-

CAD Software: Invest time in learning a robust program like Rhino or MatrixGold.

-

Post-Processing Station: A Wash and Cure Station is a game-changer, and an ultrasonic cleaner can be great for intricate washes.

-

Safety & Organization: Always wear nitrile gloves and safety glasses. Resin printing can be a bit messy, so a well-ventilated workspace and proper disposal methods for resin are essential. Always check the Material Safety Data Sheets (MSDS) for your resins!

-

Choosing Your Printer (DLP vs. MSLA vs. SLA):

-

DLP printers offer excellent speed and precision for higher volumes, but come with a higher price tag.

-

MSLA/LCD printers are fantastic for beginners and small businesses, offering great detail at an affordable price, though their LCD screens need periodic replacement.

-

SLA printers are known for smooth finishes and reliable ecosystems (like Formlabs).

-

Direct metal printing (e.g., gold or silver) is still prohibitively expensive for most jewellers and not a home setup solution. The print-to-cast method is the way to go for precious metals.

-

Tangible Return on Investment (ROI) and Business Scaling Strategies: 3D printing isn't just a cool tool; it's a strategic business asset. The cost-effectiveness comes from drastically reduced production times (up to 75%), lower tooling, labour costs, and less material waste. This leads to major long-term savings and a rapid return on your investment. It empowers you to take on more custom orders, iterate faster, and ultimately, boost your productivity and business growth.

Maximizing Your Investment in Jewellery 3D Printing

You're not just buying a machine; you're investing in your future!

Cost-Effectiveness and Rapid Return on Investment

By cutting down on design time, prototyping costs, and overall production timelines, your 3D printer can pay for itself surprisingly quickly. Imagine all the custom pieces you can now offer, or the increased volume you can achieve!

Boosting Productivity and Business Growth with Your 3D Printer for Jewellery

With a 3D printer, you can take on more projects, experiment more freely, and offer unique, personalized customization options to your clients that traditional methods simply can't match. This isn't just about making things; it's about making your business thrive.

Future Trends and Innovations in Jewellery 3D Printing

The world of 3D printing is constantly evolving, and jewelry making is right at the forefront!

Advancements in Speed, Precision, and Materials

Expect even faster printers, even finer details, and more innovative resins that push the boundaries of what's possible.

Sustainable Practices and Eco-Friendly Materials for Jewellery Making

The industry is moving towards more environmentally conscious choices, with a growing focus on sustainable resins and more efficient processes.

Personalized Customization and Market Prospects in Jewellery Design

The ability to offer truly unique, custom-designed pieces is a massive market opportunity. Imagine creating one-of-a-kind engagement rings or personalized pendants with intricate details – the possibilities are endless.

Conclusion: Your Guide to a Future in Digital Jewellery Craftsmanship

So there you have it! Choosing a 3D printer for jewelry making in 2025 is an exciting step into a world of endless creative possibilities. Remember to prioritize resolution, material compatibility (especially castable resins!), and the overall workflow efficiency. Don't forget those crucial post-processing steps and safety protocols.

Whether you're looking to enhance your hobby or revolutionize your professional studio, embracing 3D printing will undoubtedly transform your approach to jewelry design and manufacturing. Get ready to sculpt, print, and shine! The future of digital jewelry craftsmanship is waiting for you!

Related Aricles:

Essential 3D Printing Tools Guide: From Basics to Advanced, Mastering Key Tools

Choosing the Best Resin 3D Printer for Beginners

Share:

How to Make Resin 3D Printed Jewelry: A Step-by-Step Guide

Why Is Nothing Appearing in My Resin 3D Printer? A Troubleshooting Guide