If you are an architect, student, or simply emotional about the model, you have probably faced the challenge of showing your designs in an impressive way. This is the place where the 3D printer for the architectural model comes into the game: a device that not only converts your blueprint into physical objects, but also increases your presentation at another level.

Today, we tell you why the resin 3D printer is the best option for your architectural model, what features you should seek when choosing one, and what the most outstanding recommendations are. Everyone explained clearly, so you can confidently decide which one suits your needs.

Why Resin Technology is Superior for Architectural Visualization

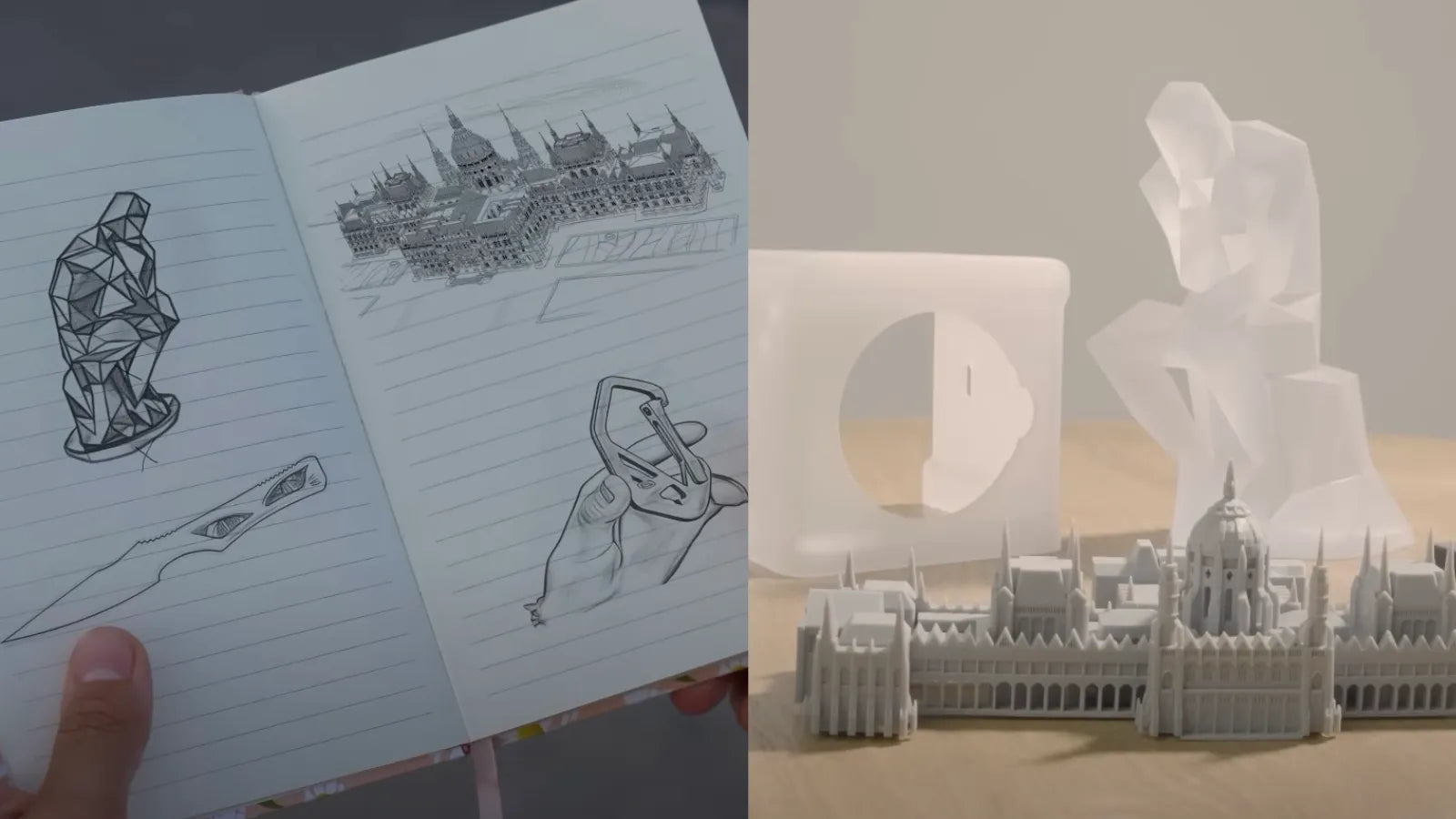

When we talk about architecture, the details make a difference. A model is not just one object. This is the physical representation of a project, which will become the reality of the preview of the reality. And to express the essence of your designs, you need a technique that guarantees an accurate and quality finish.

This is the place where the resin stands out on the filament (FDM). The resin-based 3D printer for architectural models allows for smooth surfaces, fine lines, and an allegiance that also surprises customers' demand. This is not only about printing, but is also true about how a building will look in reality.

Capturing Fine Details: From Window Mullions to Intricate Facades

Intricate facades, delicate railings, or small window frames are elements that bring a model to life. Resin reproduces each of these details clearly and sharply. If you are looking for the best quality when it comes to capturing the smallest details when printing, a good printer is for you, but which one can you acquire?

While it is true that there are a variety of alternatives on the market, one model that is a 10 out of 10 is the HeyGears Reflex RS printer. This model is used widely in architectural studios for accuracy in capturing complex geometry.

This resin 3D printer becomes a great ally because it integrates a C5-grade Z-axis module that guarantees a uniform layer thickness, making your models showcase sharp lines and impeccable proportions. This means that when you present your proposals, the visual quality of the models will speak for you and convey confidence in your work.

While modern resin printers offer improved reliability, like any 3D printing technology, they require proper calibration and maintenance to maintain consistent performance and precision over time. The full-field screen calibration ensures consistent results with every print, while the dynamic motion algorithm 3.0 speeds up the process by up to 33% without compromising quality. That practical advantage can make the difference between impressing a client and missing a deadline.

Achieving Flawless, Smooth Surfaces for Professional Presentation

Smooth surfaces are important when presenting the project to a customer or academic jury. While resin prints have a smoother starting surface than FDM prints, they are not ready for professional presentation straight off the printer. Essential post-processing includes:

Removing supports, which leave marks that need to be sanded smooth.

Washing the print in alcohol to remove uncured, sticky resin.

Often, a final curing step under UV light is required after washing.

Sanding is frequently necessary to achieve a truly flawless, presentation-ready finish.

The Importance of Dimensional Accuracy in Scale Models

A scale error, even if minimal, can ruin the perception of your design. Resin ensures reliable dimensional accuracy, meaning your model will faithfully reflect every proportion of your work.

Key Features to Look for in a 3D Printer for Architectural Models

Before purchasing a 3D printer for architectural models, it is worth stopping to evaluate which features are really important. Not all printers serve the same purpose, and here we tell you what to see.

Build Volume: Balancing Model Scale and Printer Footprint

The build volume determines the maximum size of your model. You should seek a balance between the scale you need and the printer that will capture your studio. Larger build areas allow complex projects. Compact sizes save space without sacrificing output.

XY Resolution and Layer Height: The Pillars of Precision

The XY resolution and layer height are responsible for fine details and clean surfaces. The smaller the height of the layer, the more realistic and accurate your model will be. For architectural models, this can mean clearer textures and a more professional presentation.

Print Speed and Reliability for Professional Deadlines

In architecture, the time limit is often tight. You need a fast and reliable printer that will not be stranded at night before a significant delivery. Consistency in performance helps ensure your projects are ready when clients expect them.

Ease of Use and Workflow Integration

If the printer is not easily integrated into your workflow with CAD or modelling software, you will waste time. Ease of use is important for working smoothly and without frustration. A seamless connection between design and print lets you focus more on creativity.

Top Resin 3D Printer Recommendations for Architects

Here we share some recommendations for 3D printers for architectural models based on the most common needs in architectural practice.

For High-Detail Conceptual and Massing Models

For initial concepts or massing models, you need printers that prioritize detail and speed. Compact resin models with high resolution work very well at this stage. They help communicate design intent clearly.

For Large-Scale Site and Urban Planning Models

If you work on urban or large-scale projects, a printer with a large build volume is advantageous. This way, you can print large pieces or divide your model into sections that fit together perfectly. This approach makes it easier to visualize entire neighborhoods and infrastructure layouts.

For Professional Studios Requiring High Throughput and Durability

Studios that produce models constantly require robust printers capable of supporting long work hours without losing quality. Here, industrial equipment with engineering resins stands out. Such machines ensure consistency and reduced downtime in demanding workflows.

Beyond the Hardware: Essential Workflow Considerations

The 3D printer option for architectural models does not end with hardware. It is also necessary to consider the complete workflow: from software to post-processing.

Choosing the Right Resins: Standard, Clear, and Engineering-Grade

Standard resins are useful for most models, but also have transparent resins to simulate glass, and are engineering resins for more resistant pieces. Resin selection should be based on the specific requirements of your project, considering factors like durability, colour options, and special properties such as transparency or heat resistance.

Optimizing Your CAD and Slicer Software for Flawless Prints

A well-designed CAD model adapted to Slicer software ensures that the print is accurate. Adjustment support, thickness, and angle are important to achieve an impeccable result. Taking the time to fine-tune these settings saves valuable material during production.

Post-Processing Techniques for a Perfect Finish

Post-processing includes cleaning, treating, and painting, if necessary. These are the final stages that turn into a professional model ready to affect a common print. Attention to detail in this stage can elevate a simple prototype into a presentation-worthy piece.

Conclusion: Investing in the Right Resin 3D Printer for Your Architectural Models

Investing in 3D printers for architectural models is much higher than purchasing equipment. It is betting on a device that will allow you to present your ideas with impact, accuracy, and professionalism.

Whether you work in a large firm, are in university, or simply want to bring your personal projects to life, the resin opens the door for expansion and quality levels that are actually judged with architecture.

The right choice will not only help you save time but will also show your creativity in the best way. Finally, your resin 3D printer will not only be another piece of equipment on your desk. This will be the bridge between your digital designs and tangible reality that attracts customers and colleagues.

Related articles:

How PAH10 Resin Elevates Performance in Plastic Resin Applications

What to Do When the 3D Printer is Slowly Filling with Resin

How to Make Money 3D Printing in 2025

Share:

Resin 3D Printers: How Much Do They Typically Cost?

3D Printer Types: The Ultimate Guide to Choosing the Right One