Produkt-Highlights

- Ergebnisorientierte Druckstrategien

- Intelligentes KI-Peeling-Kraftmanagement

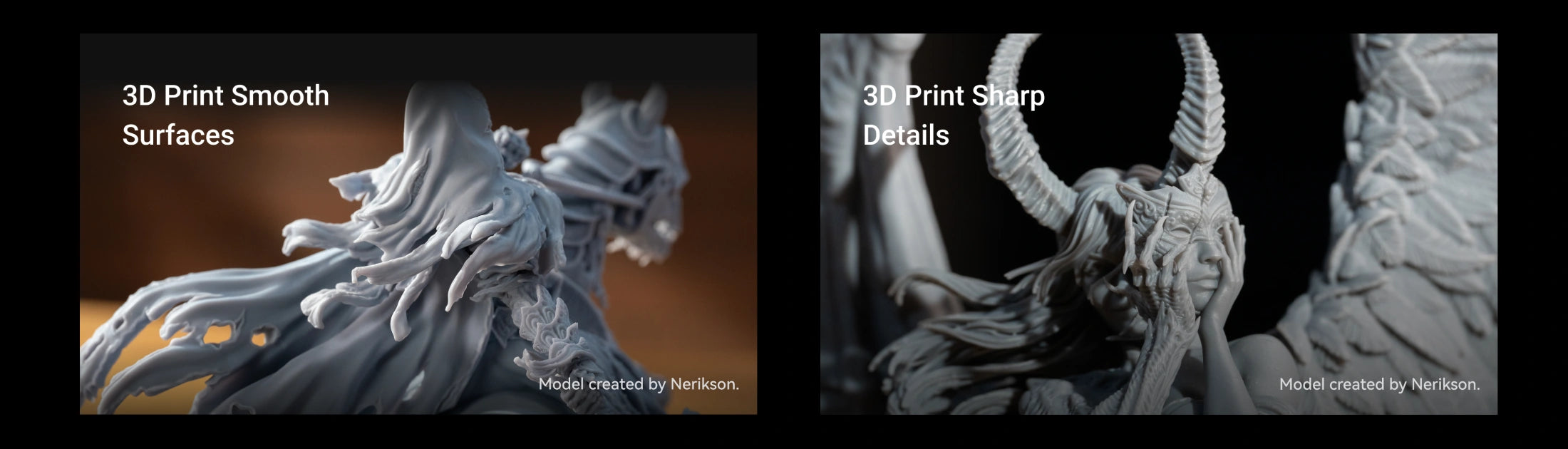

- 33μmPräzision

- Auto-Harzstandserkennung

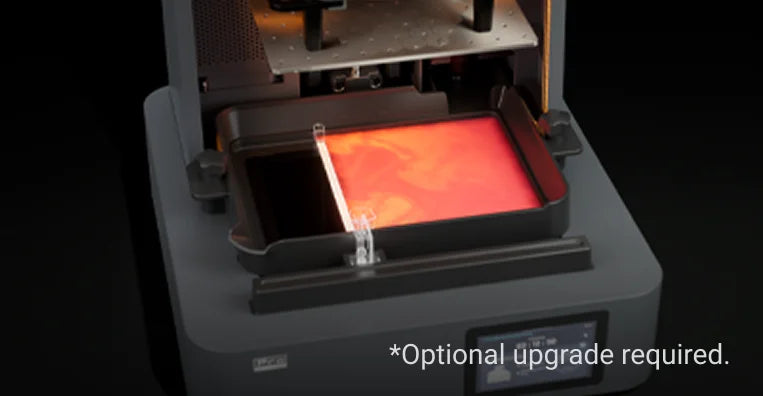

- Auto beheizte Ablage

- 90,6 % Detailwiederherstellungsrate

- 90% Konsistenz

Kompatible Harze

Reflex 2 ist derzeit mit folgenden Materialien kompatibel: PAC10, PAU11, PAH10 Schwarz, PAT10, PARP10 Orange Clay, PAP10 Ash Grey, PAWR10, PAS10 Schwarz, PAF10, PAS10 Pale Purple (unter Verwendung des Pulsing Release Module 2), PAH270, PAT10, PAE10, PAU20.

Lieferumfang

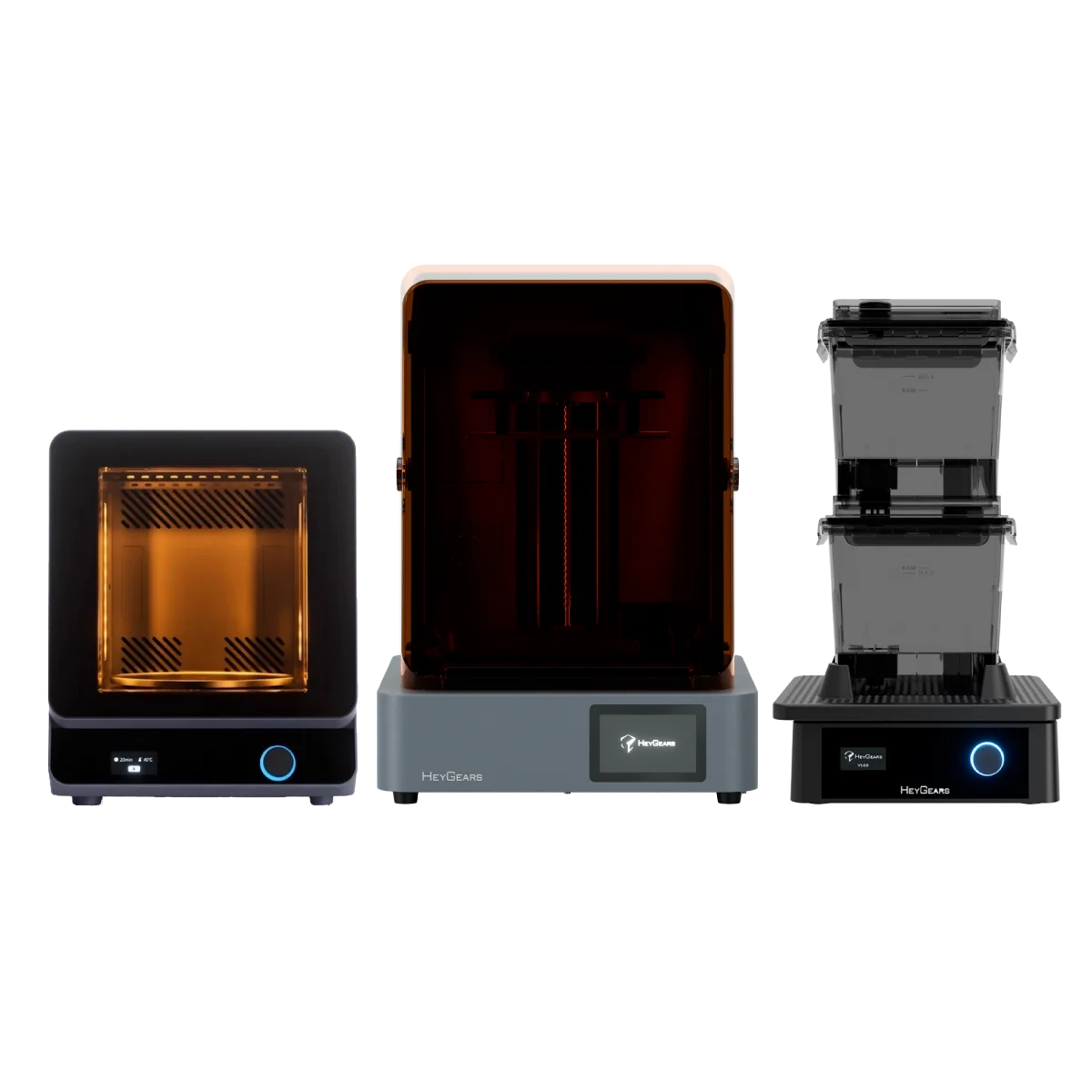

Reflex 2:

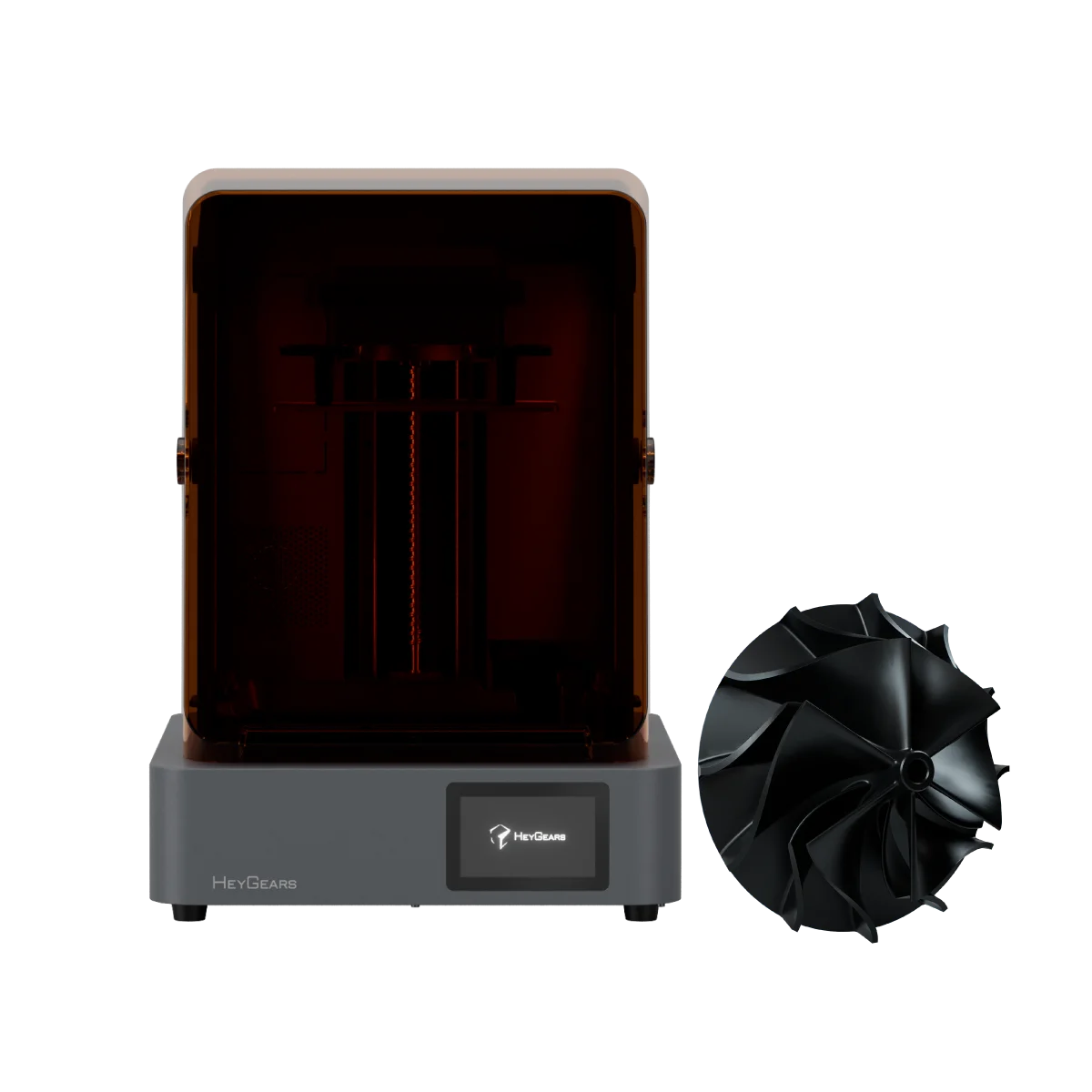

Reflex 2 3D-Drucker x1

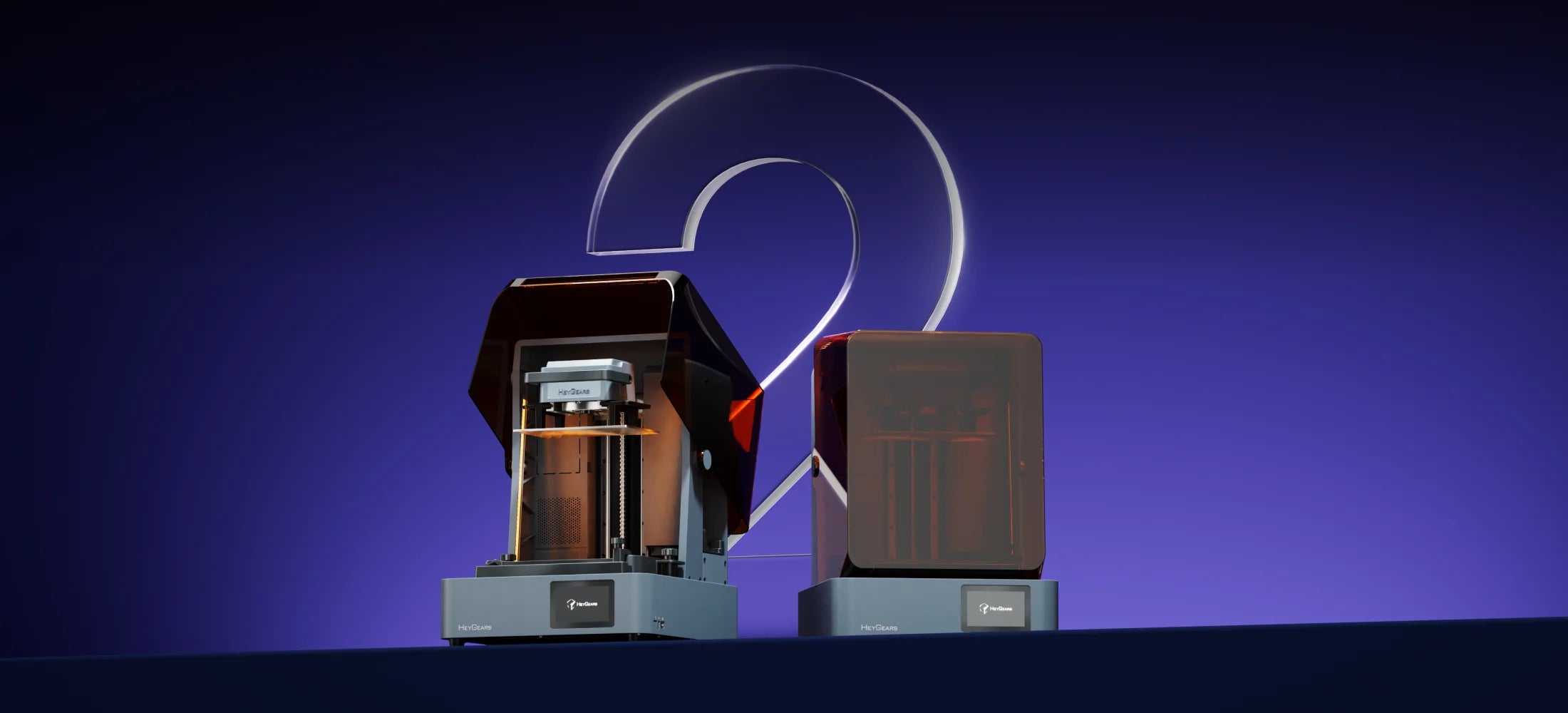

Reflex 2 Combo:

Reflex 2 3D-Drucker x1

Waschen x1

Cure x1

Reflex 2 mit Impulsauslösemodul-Kit:

Reflex 2 3D-Drucker x1

Impulsfreigabemodul 2 x1

Reflex 2 Beheizter und pulsierender Harzbehälter x1

Passt gut zu

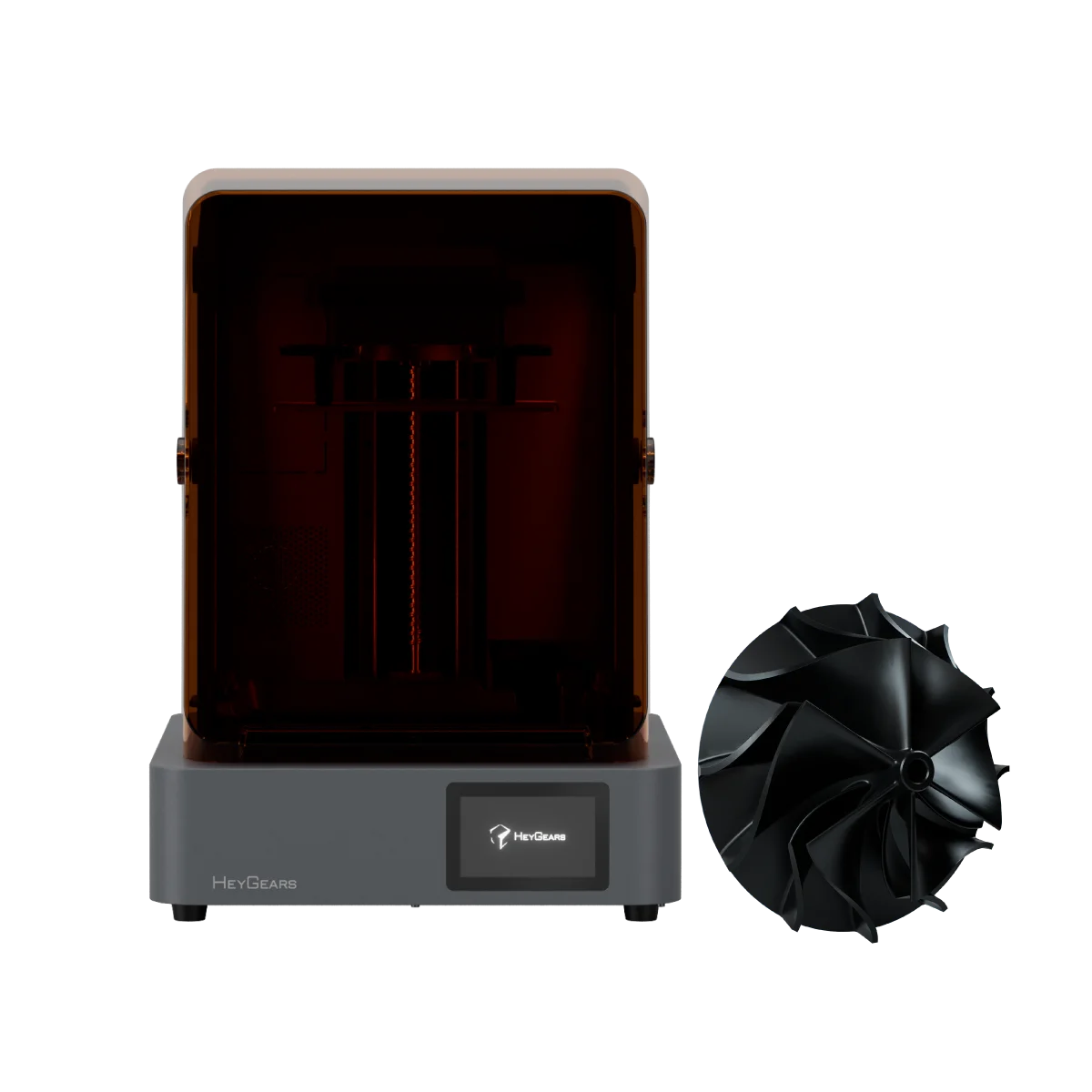

UltraCraft Reflex 3D-Drucker

Wir sind bestrebt, Ihnen den bestmöglichen Service zu bieten. Zögern Sie nicht, uns bei Fragen zu kontaktieren.

-

Versandinformationen

Kostenloser Versand ab einem Bestellwert von 399 $. Klicken Sie hier für weitere Versandinformationen.

-

Kundensupport

Benötigen Sie Hilfe? Wir sind für Sie da!

WhatsApp:

+1 949-283-2998 (USA)

Montag bis Freitag, 9:00 bis 17:00 Uhr PSTE-Mail-Support:

contact@heygears.com

Technische Unterstützung:

customersupport@heygears.com

-

Los geht's

Erste Schritte mit Ihrem HeyGears 3D-Drucker

-

Häufig gestellte Fragen

Weitere Informationen finden Sie in unseren FAQs .

Hear It From Our Users

Warum Reflex 2 wählen?

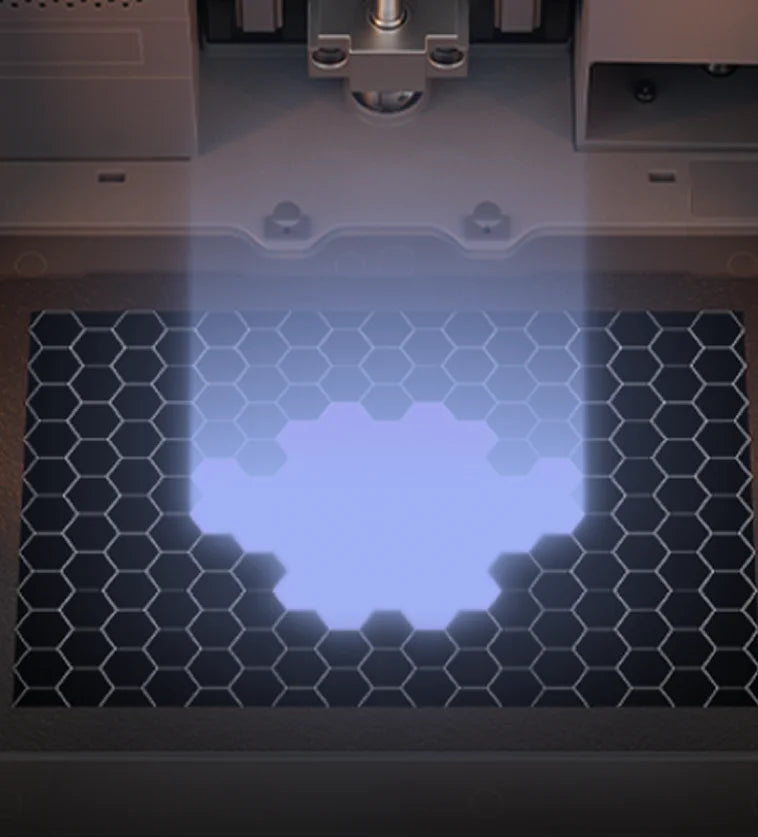

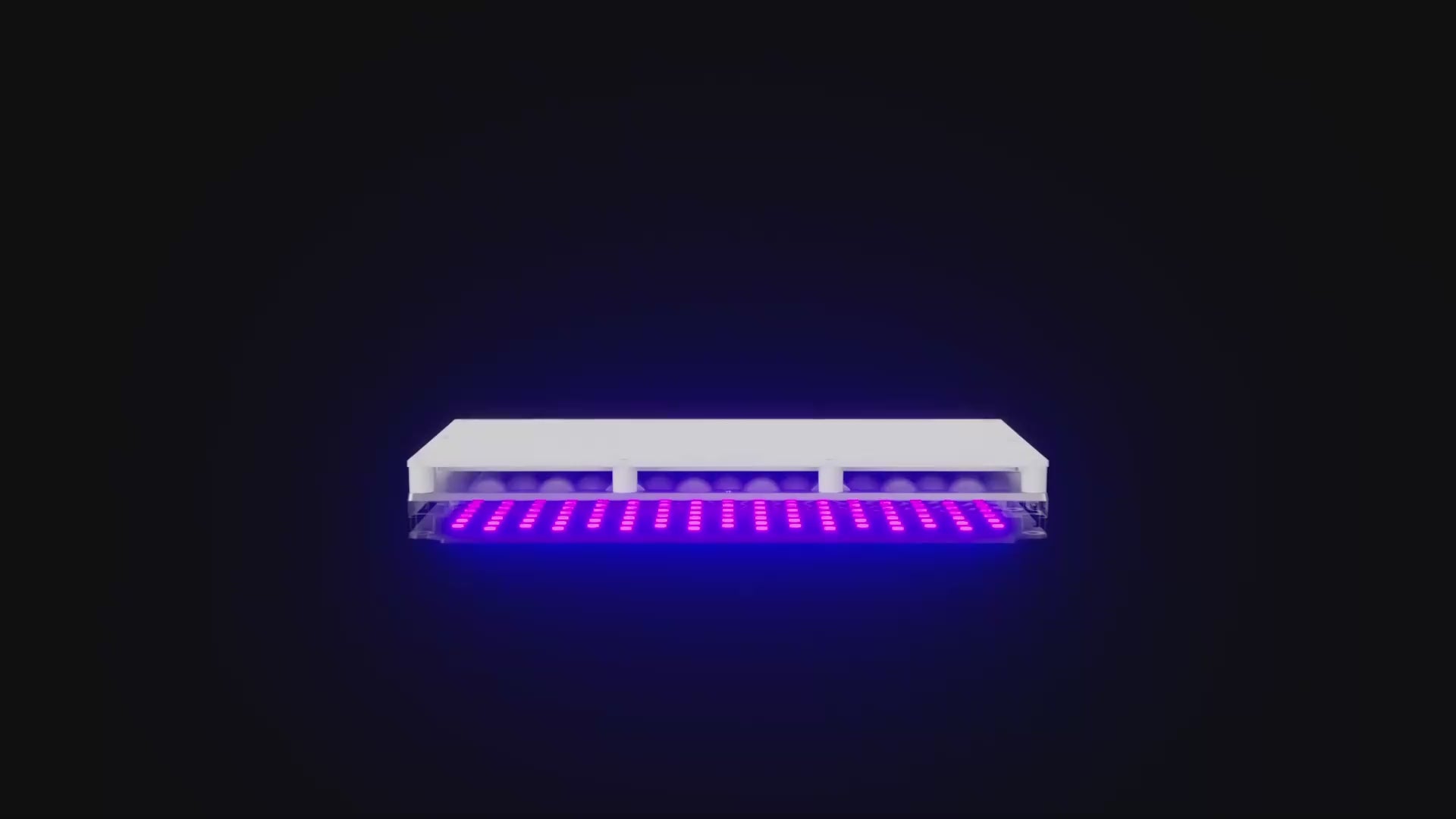

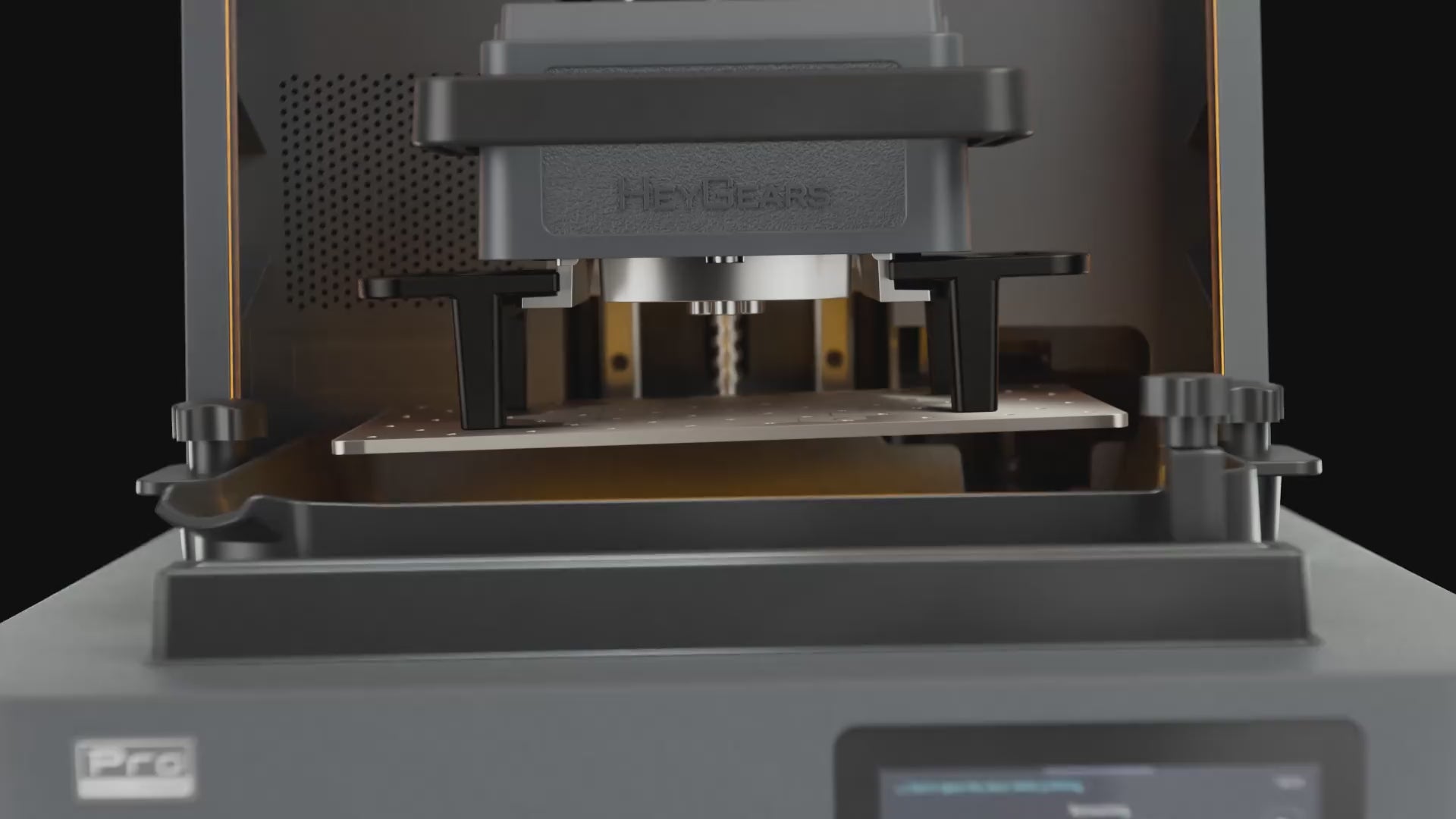

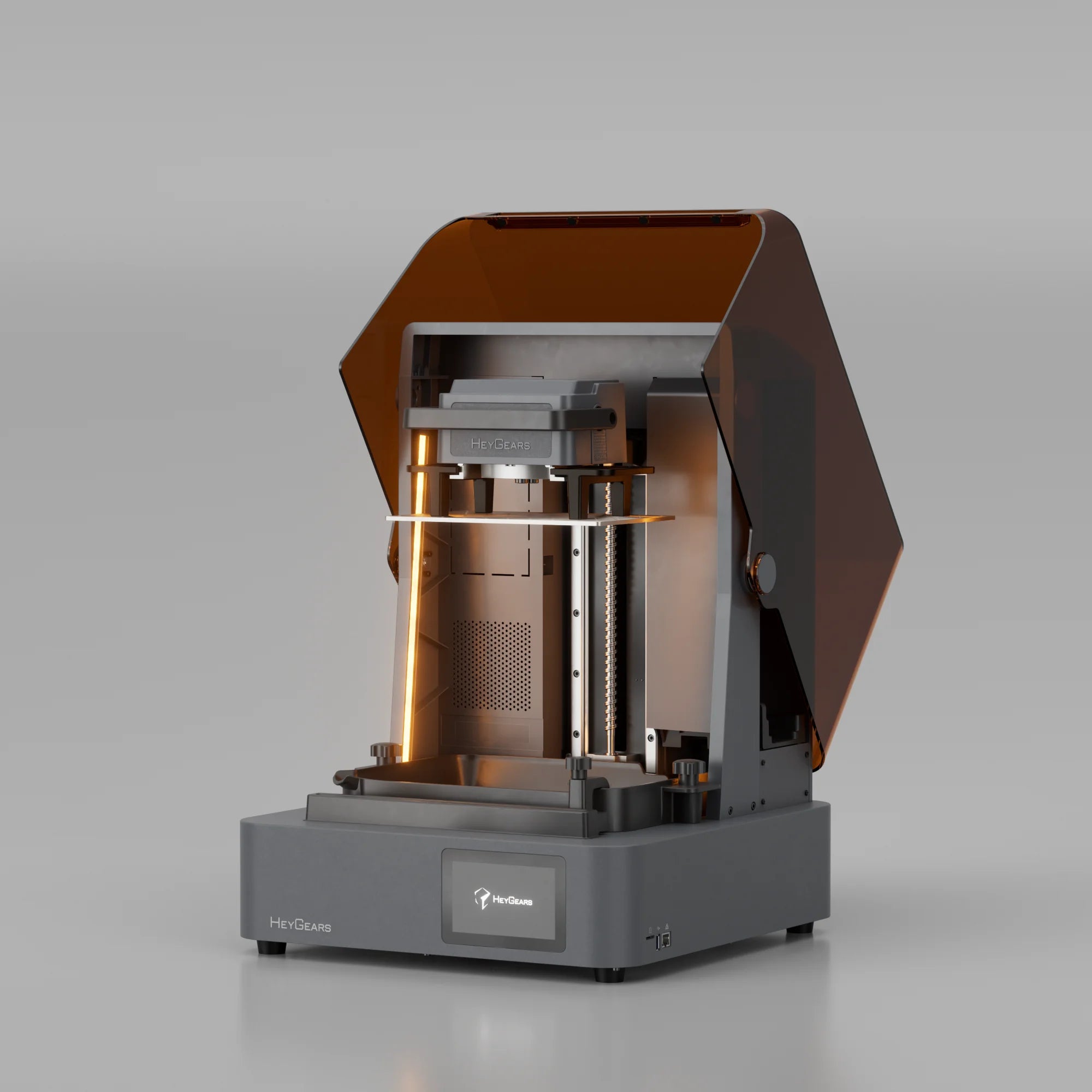

161 OptiZone Lichtmodul, entwickelt von HeyGears

KI-gestützte Lichtkalibrierung mit über 86.000 Zonen für unübertroffene Lichtgleichmäßigkeit

Der verbesserte visuelle Kalibrierungsalgorithmus MASK nutzt 86.020 Kalibrierungszonen, um Schwankungen der Lichtintensität in jeder Siebzone auszugleichen. Mit diesem Verfahren wird eine Lichtgleichmäßigkeit von ≥ 94 % und eine Druckgenauigkeit von ≤ 0,05 mm* erreicht.

*Datenquelle: HeyGears Lab.

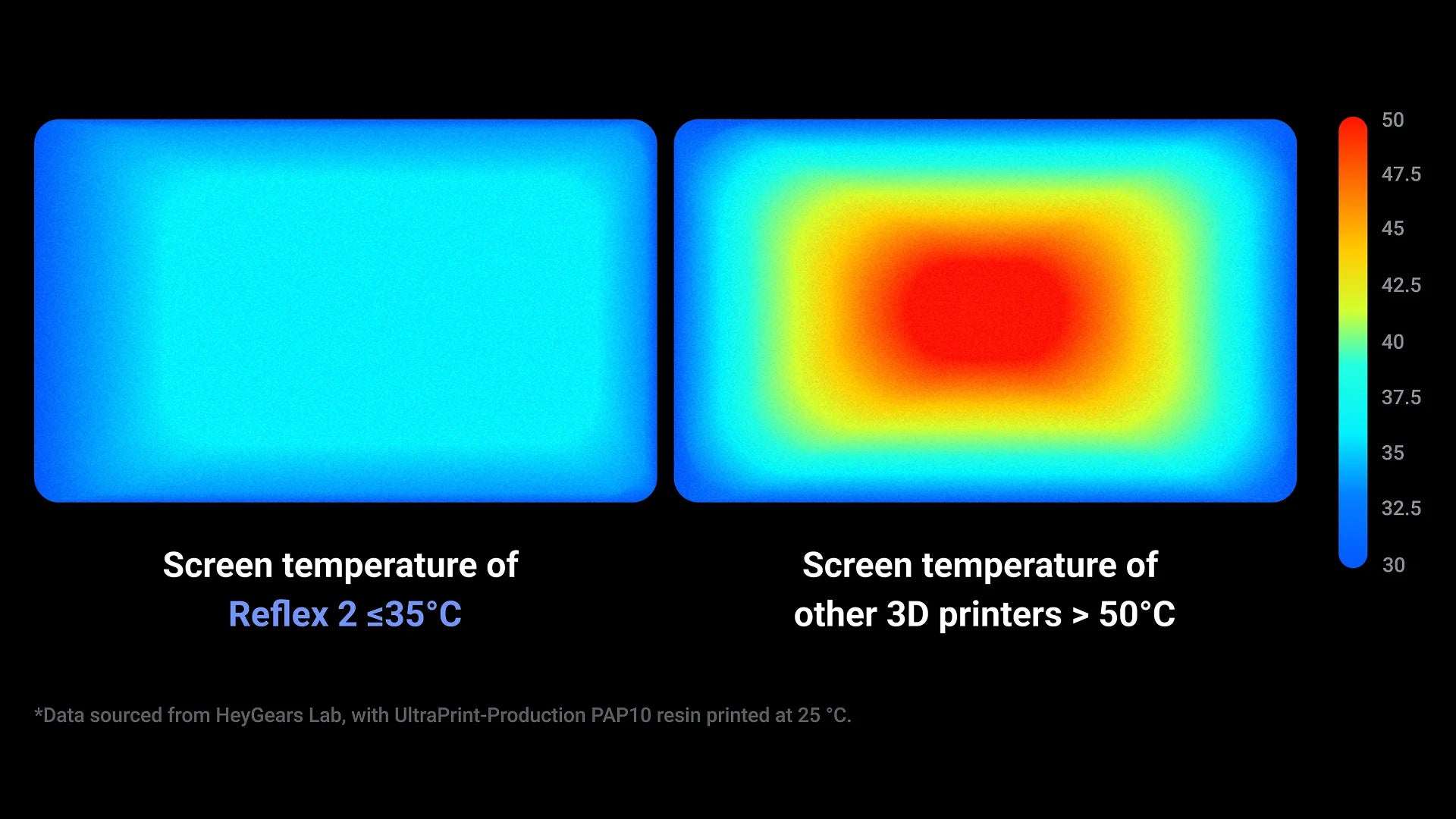

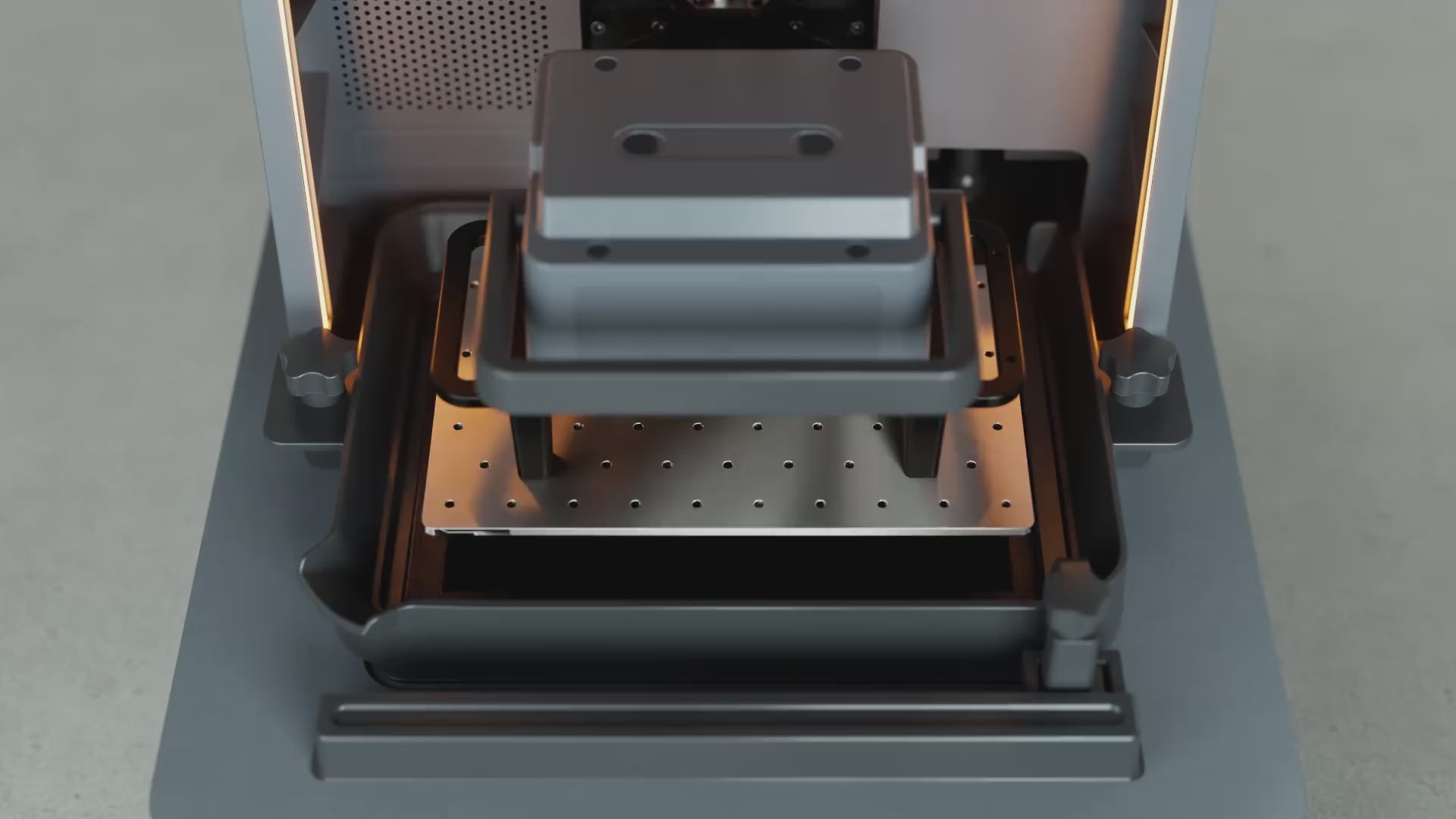

Verbesserte Zuverlässigkeit beim 3D-Druck

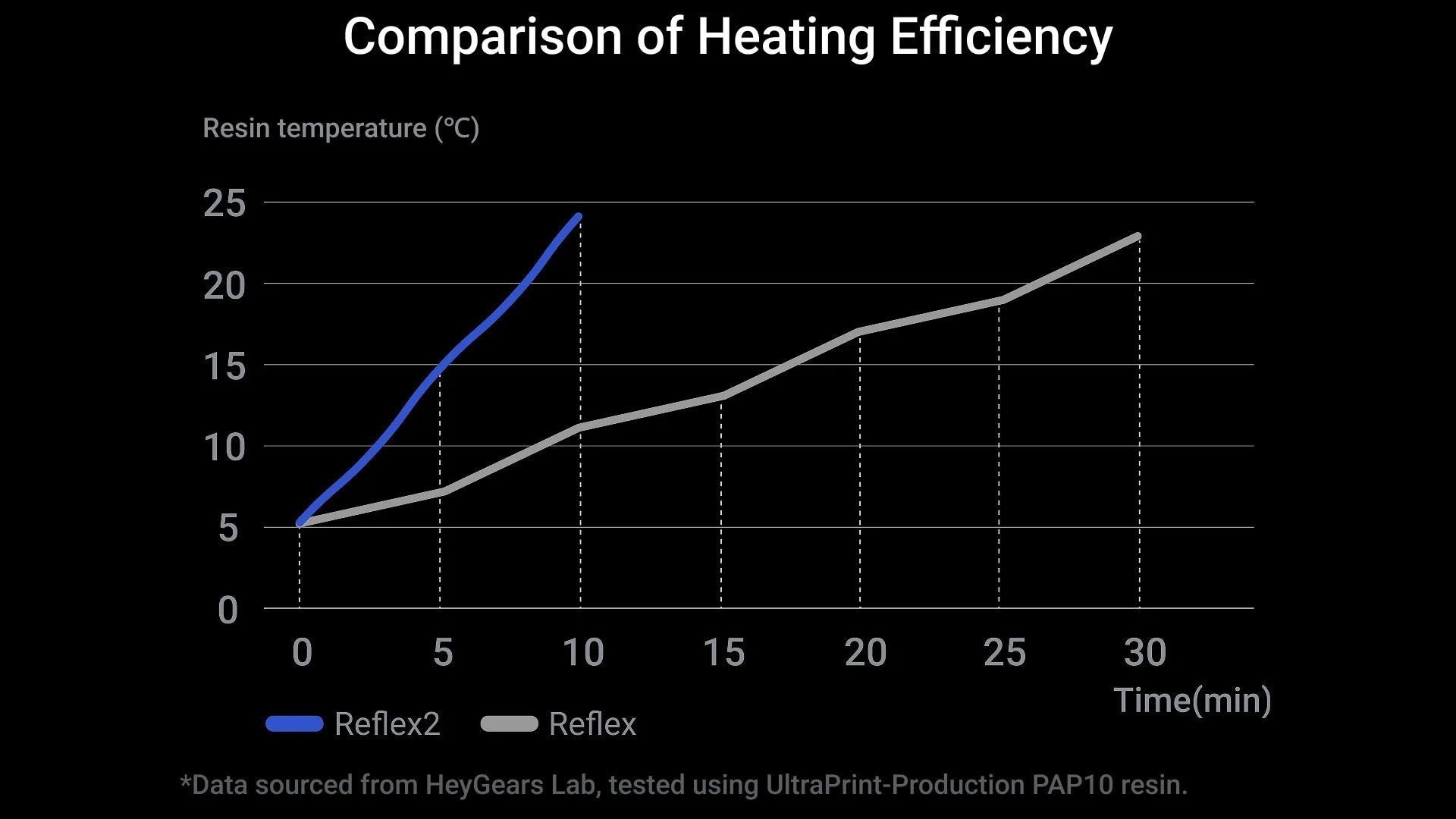

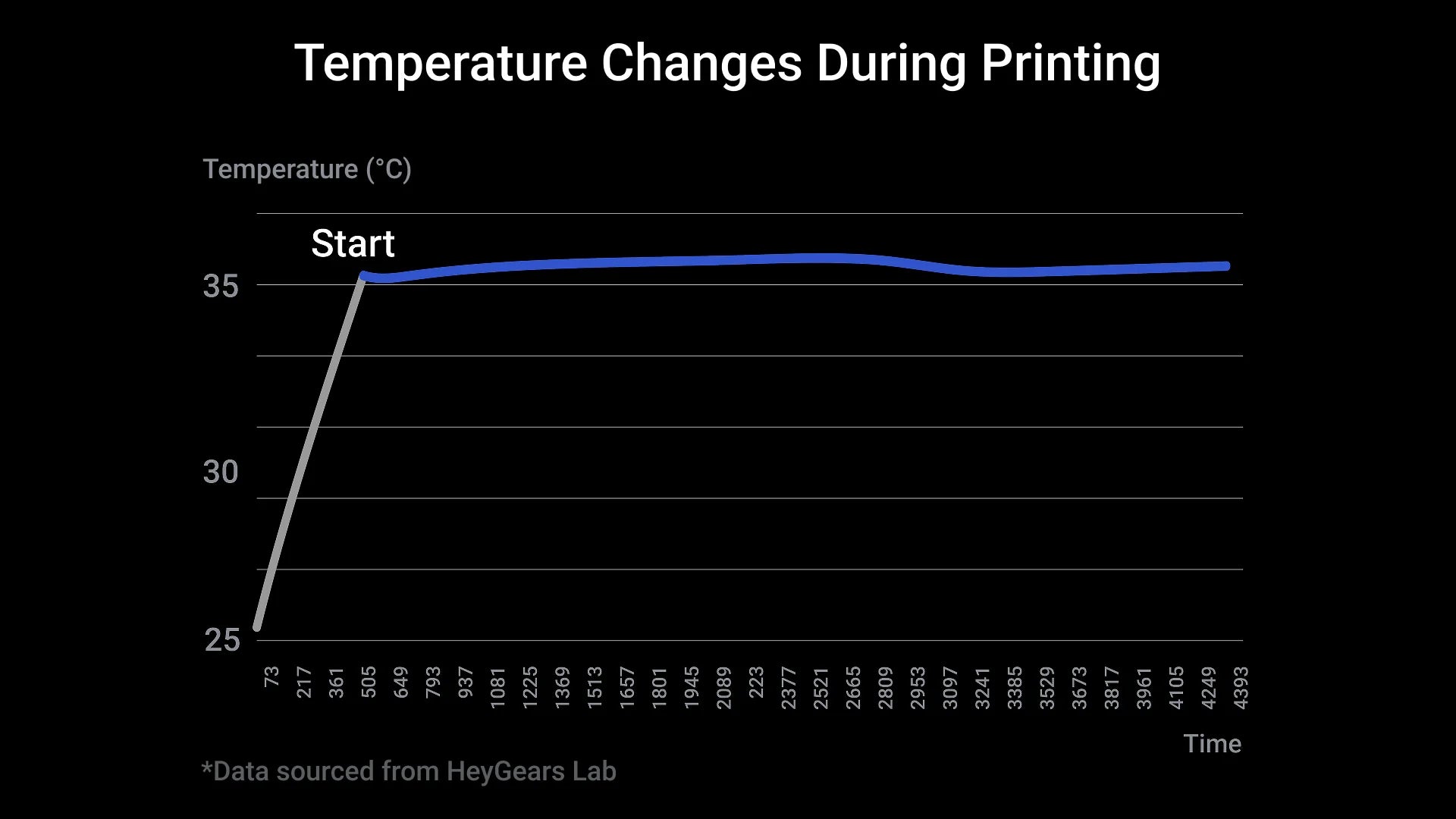

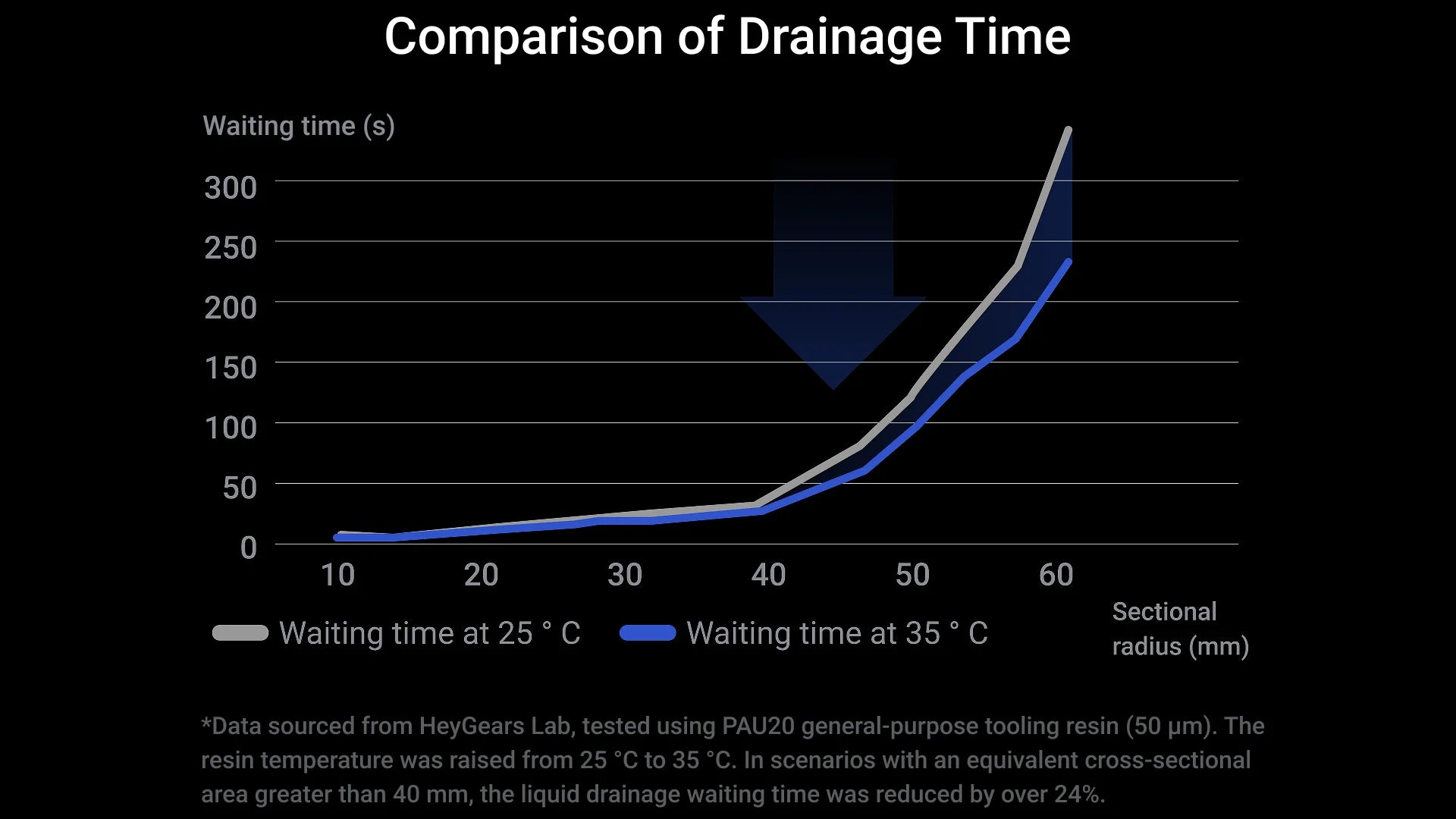

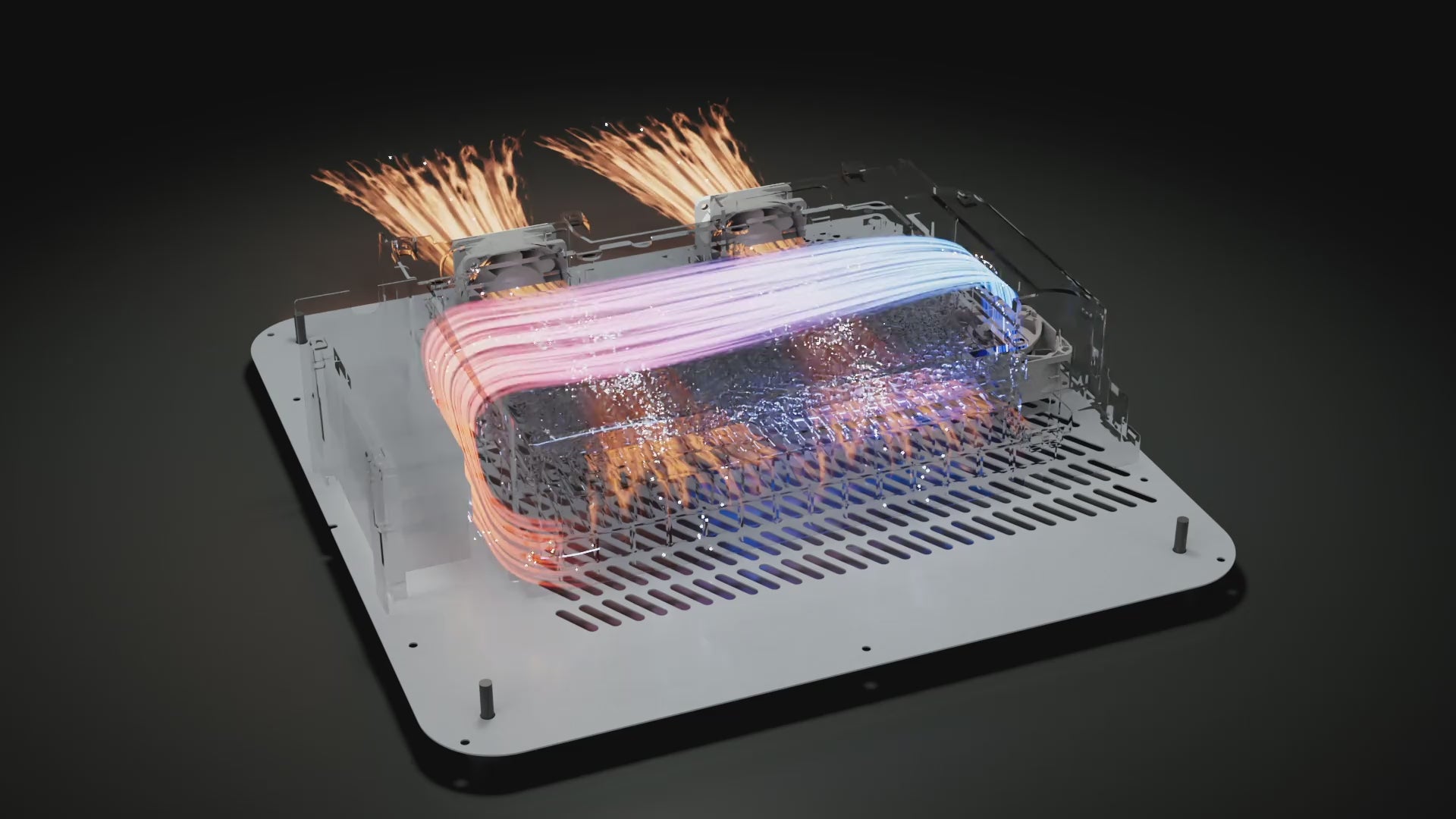

Intelligente Temperaturregelung

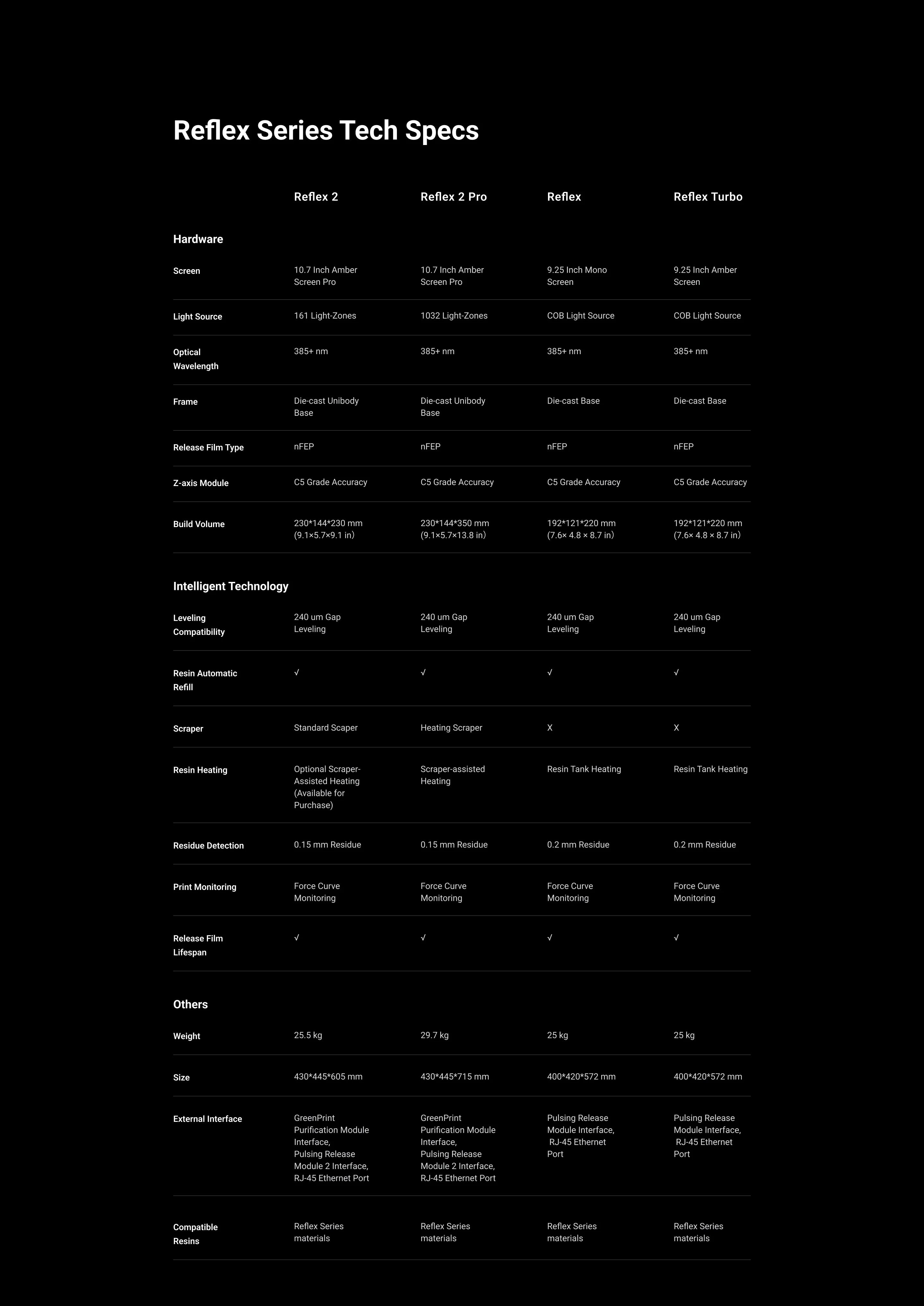

Spezifikationen

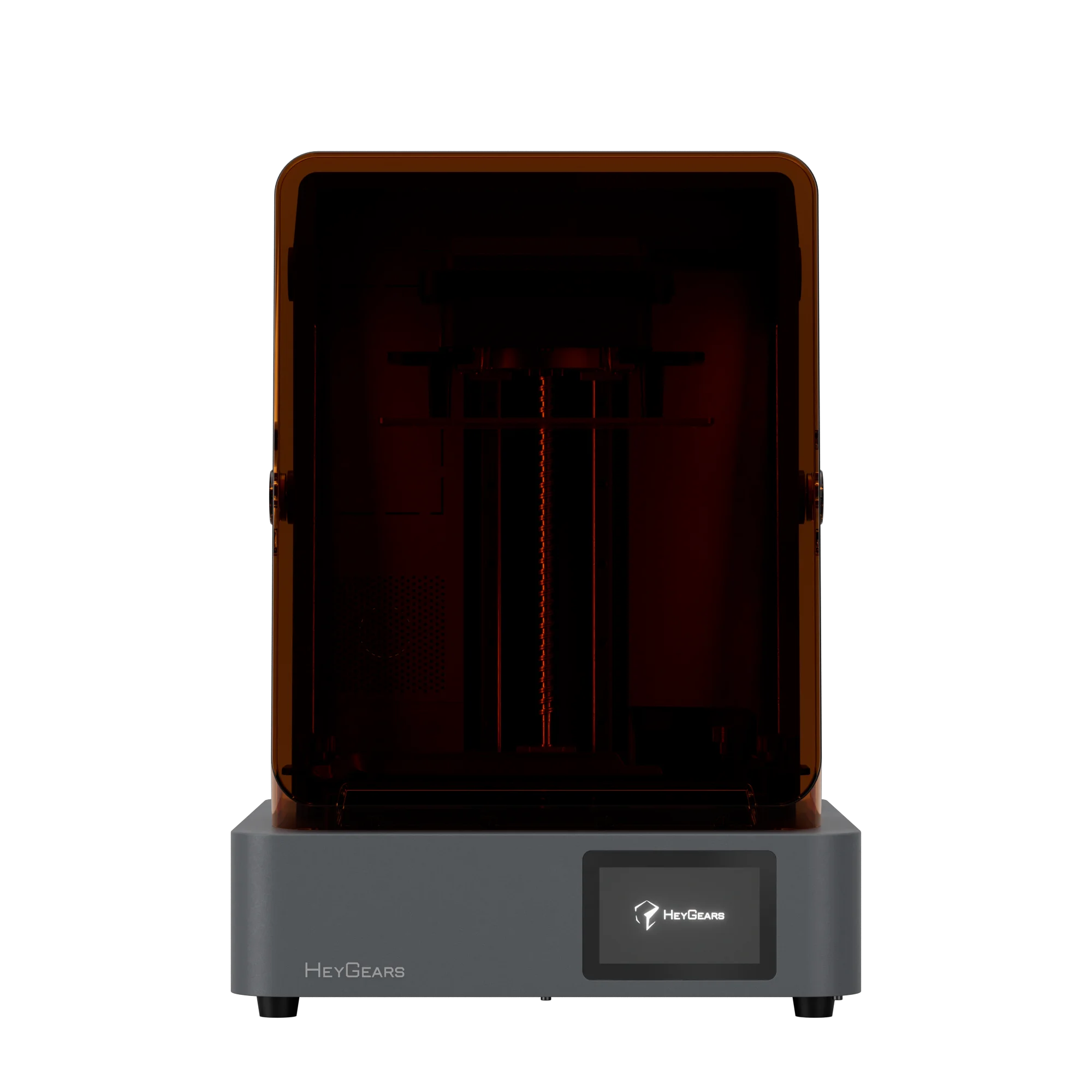

Produktname:

UltraCraft Schnellproduktionssystem

Produktmodell:

UltraCraft Reflex 2

Marketingname

Reflex 2

3D-Drucktechnologie:

LCD (MSLA)

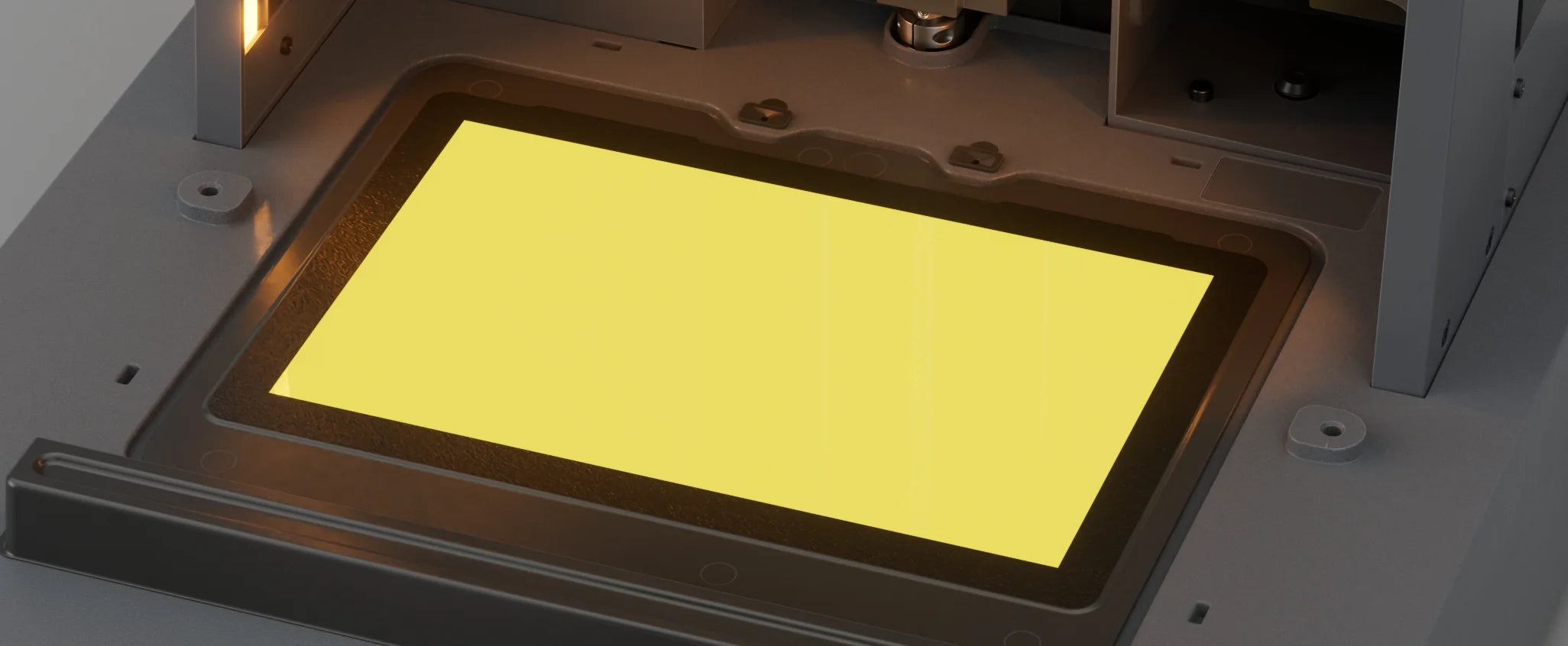

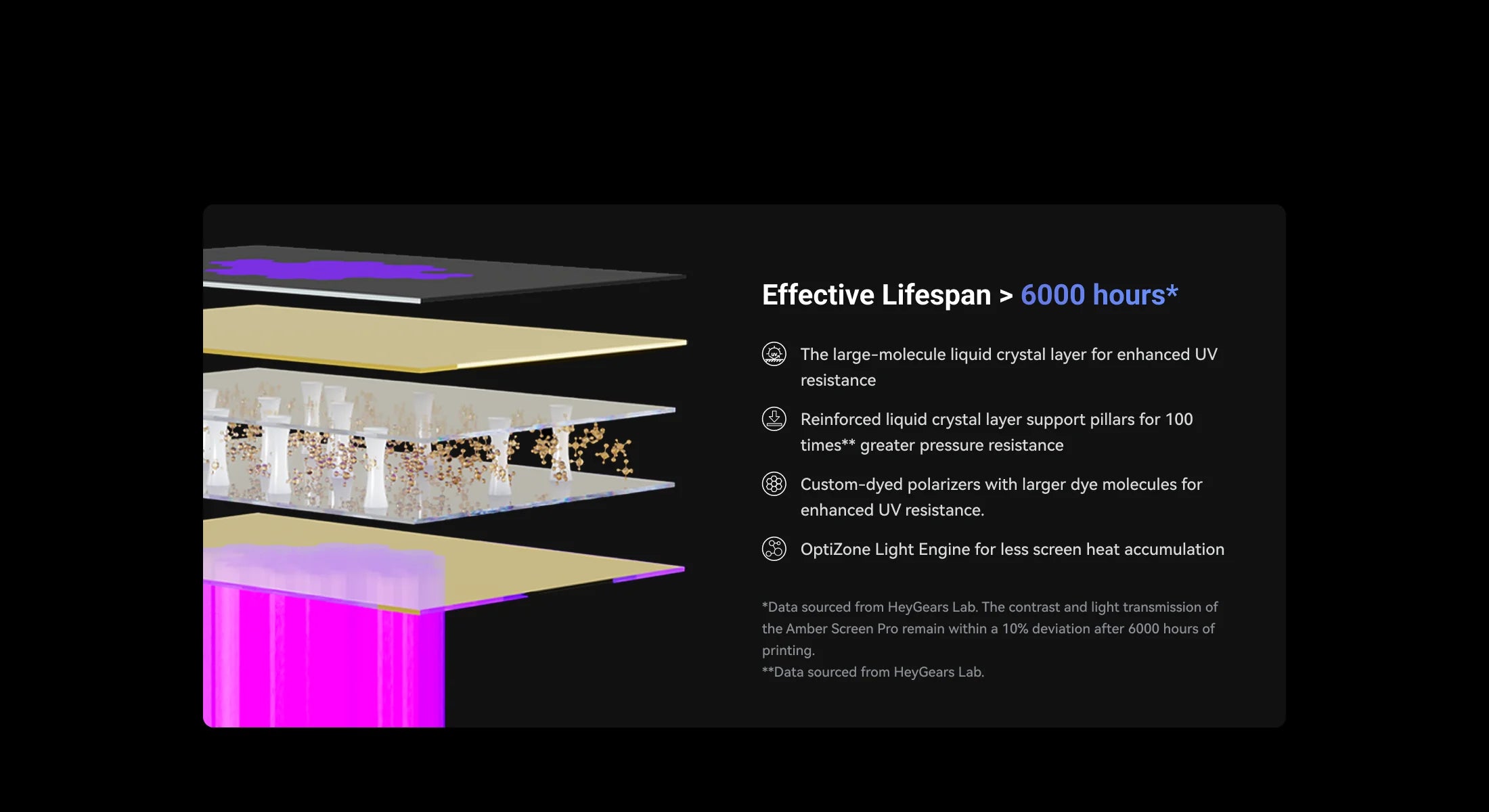

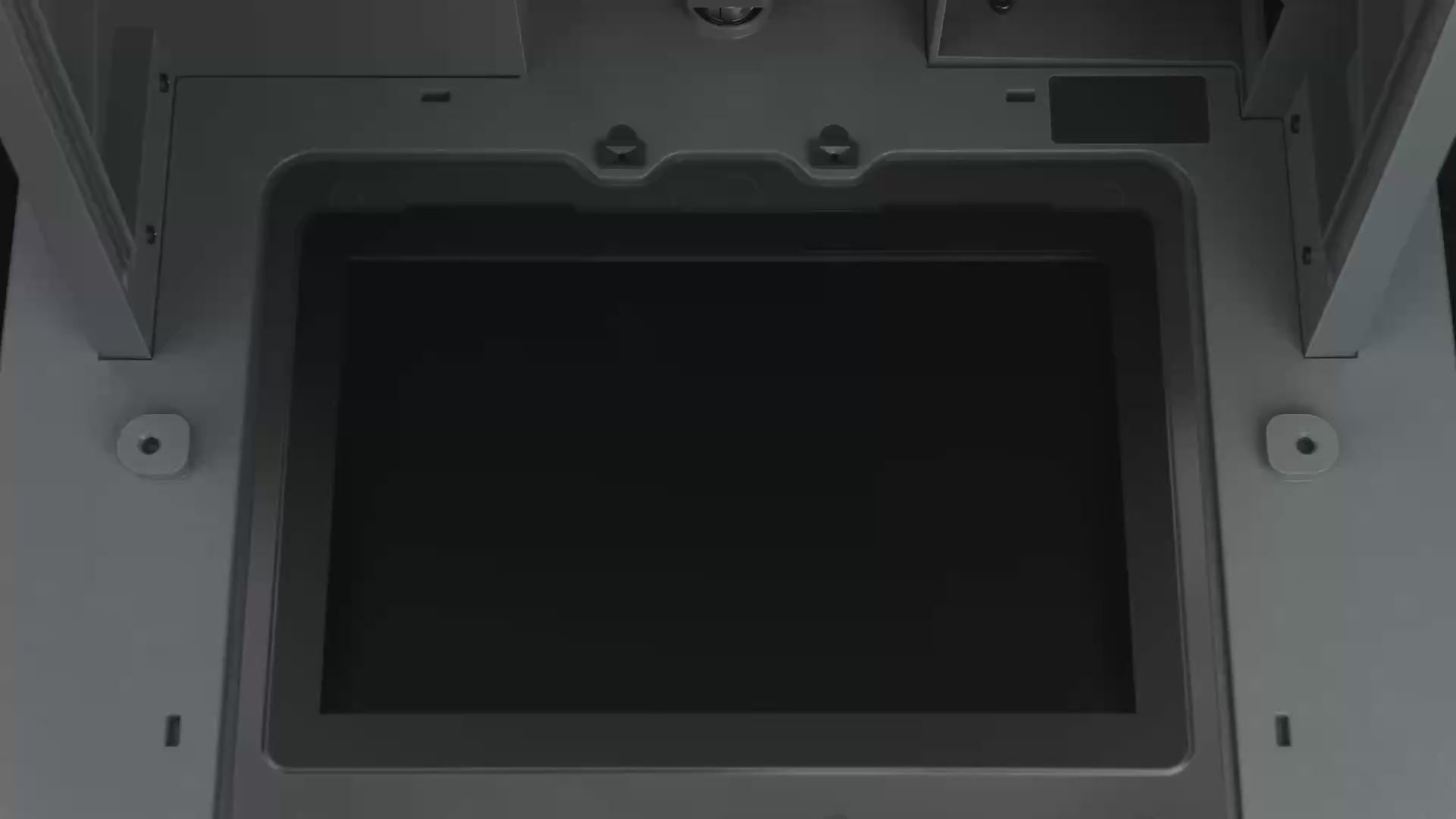

Bildschirm:

10,7 Zoll 6K Amber Screen Pro

Optische Wellenlänge:

385+ nm

Lichtquelle:

161 Lichtzonen

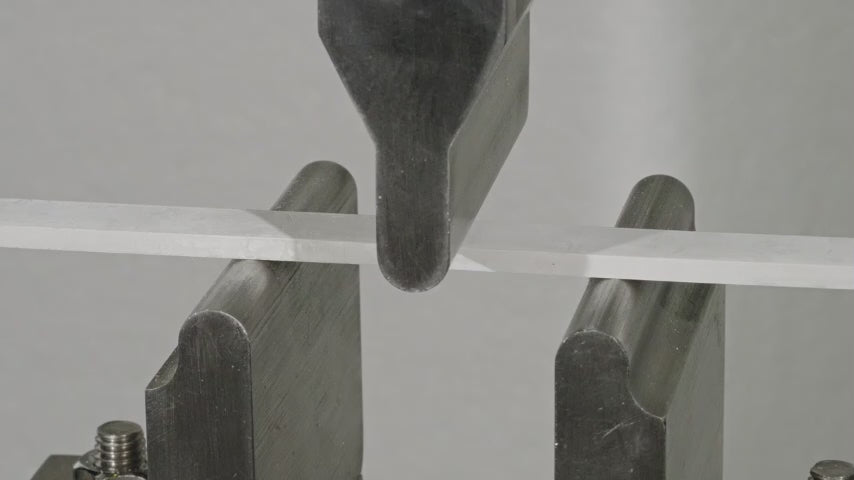

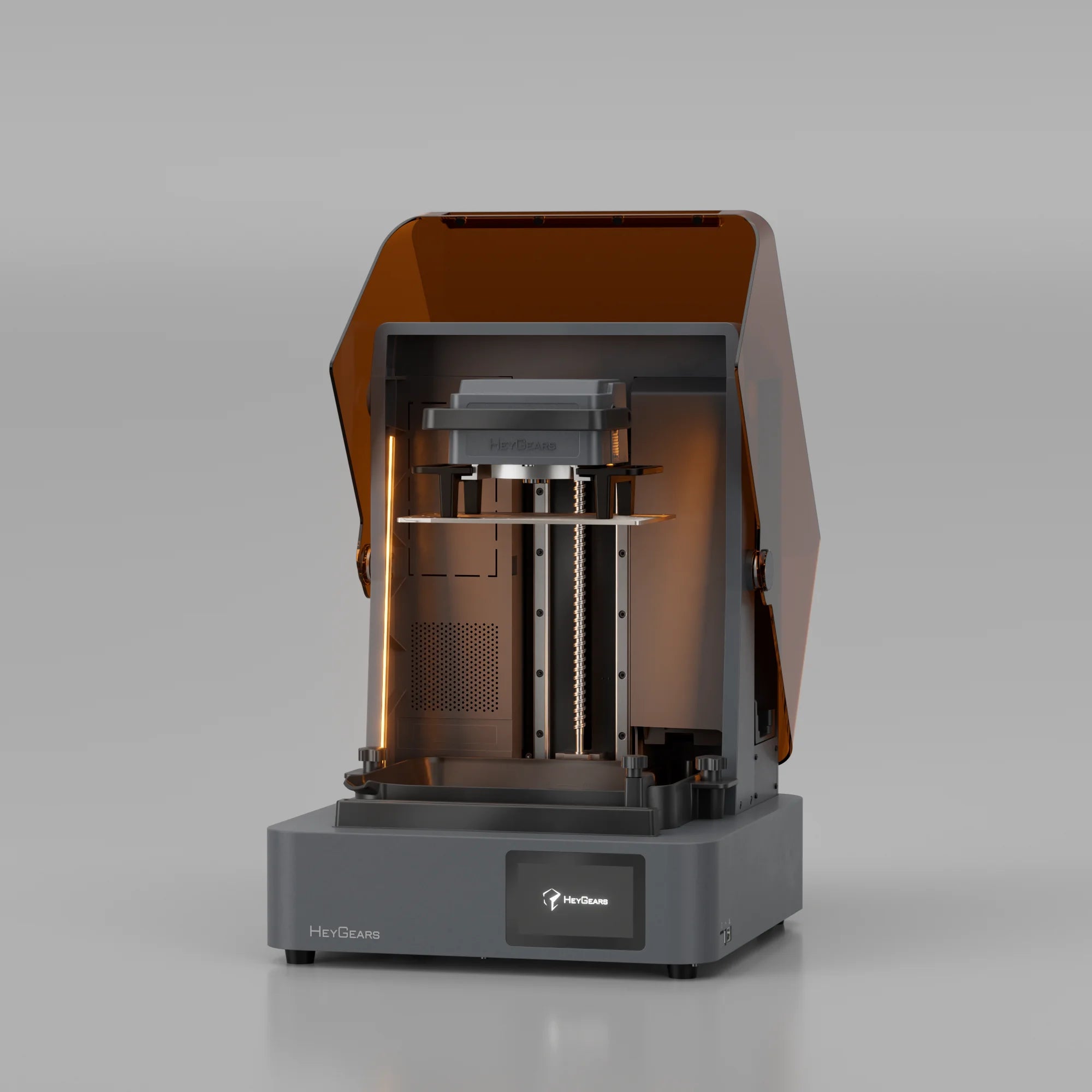

Z-Achsen-Modul:

C5-Notengenauigkeit

Bauvolumen:

230 × 144 × 230 mm

(9,1 × 5,7 × 9,1 Zoll)

XY Native Pixel:

40 μm

Genauigkeit:

±20 μm

Schichtdicke:

20-250 μm

Harzerwärmung:

Optionale Schaberunterstützungsheizung

(Erhältlich)

Rückstandserkennung:

0,15 mm Rückstand

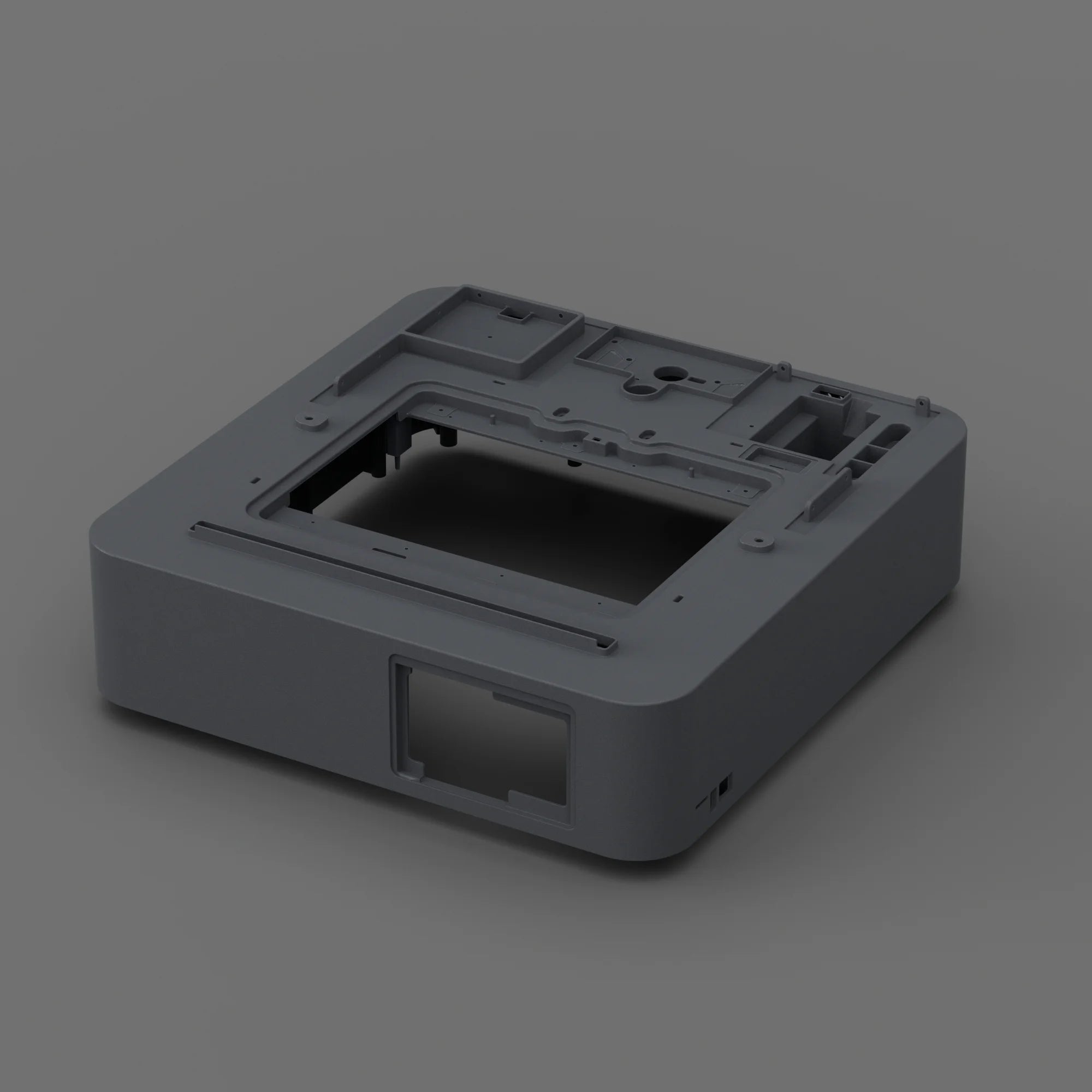

Rahmen:

Unibody-Basis aus Druckguss

Gewicht:

25,5 kg

Nennleistung:

350 W

Stromspannung:

100–240 V~50/60 Hz

Größe:

430 x 445 x 605 mm

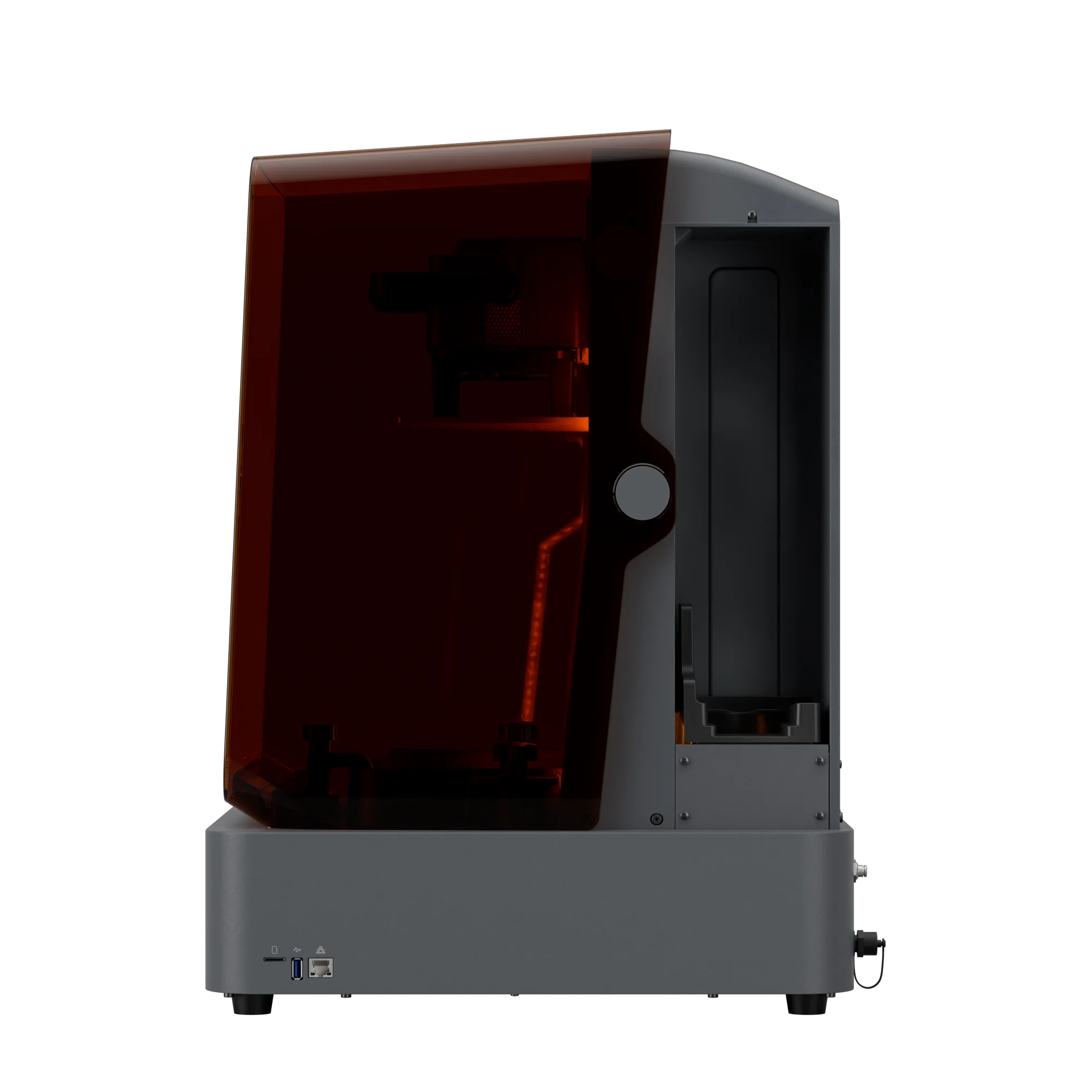

Externe Schnittstelle:

• Schnittstelle zum GreenPrint-Reinigungsmodul

• Schnittstelle für Impulsfreigabemodul 2

• RJ-45-Ethernet-Anschluss

Konnektivität:

USB, WLAN, LAN

Sprache:

Englisch, Vereinfachtes Chinesisch

Kompatibles Harz

Kompatibel mit allen Materialien der Reflex-Serie

Lieferumfang

Drucker

Normaler Schaber

Spatel

Netzkabel

Werkzeug zum Entfernen von Teilen

Harztank

Plattform erstellen

Harz-Nachfülldeckel

T-Schlüssel

Schnellstart

Kundendienstleitfaden