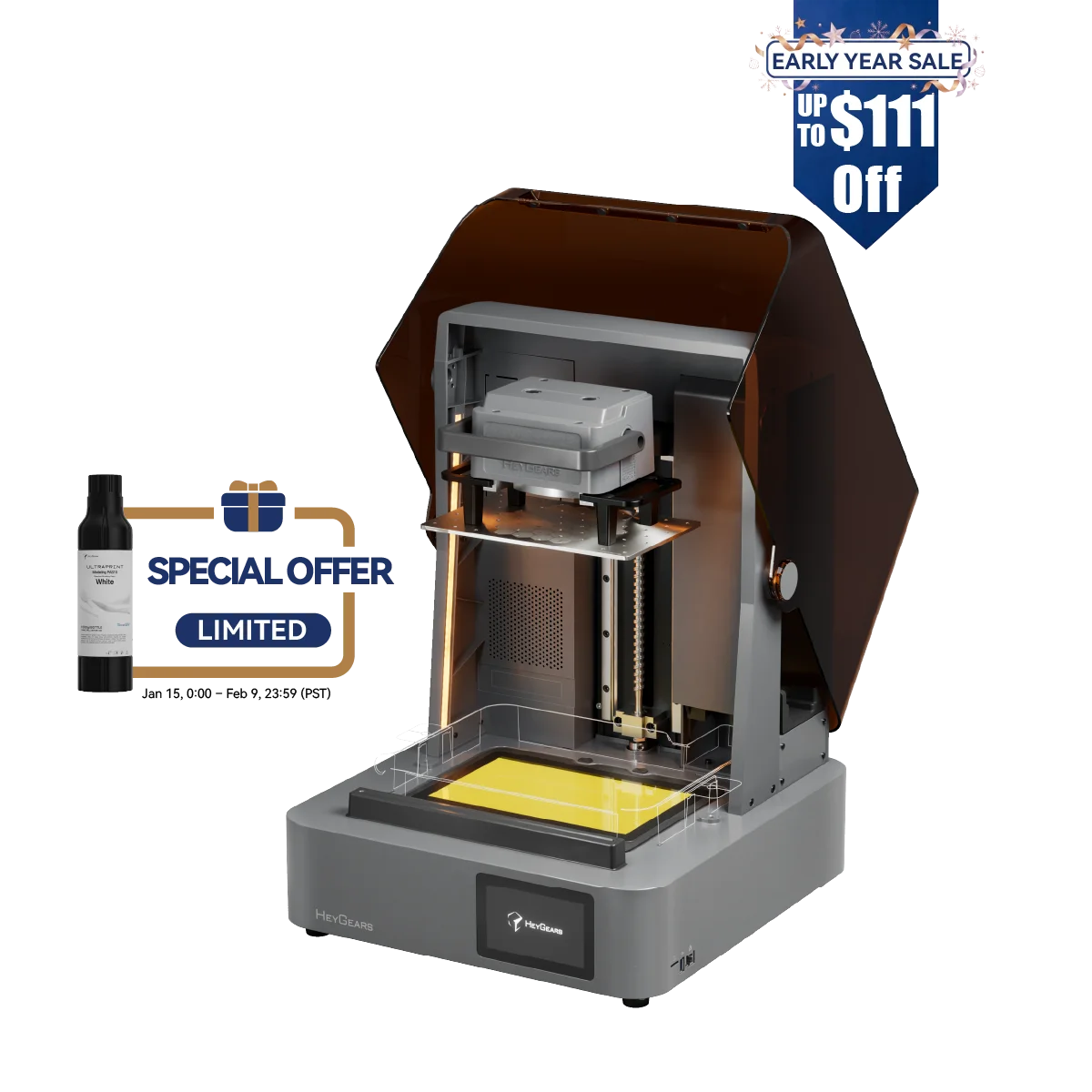

製品のハイライト

- 結果重視の印刷戦略

- スマートAI剥離力管理

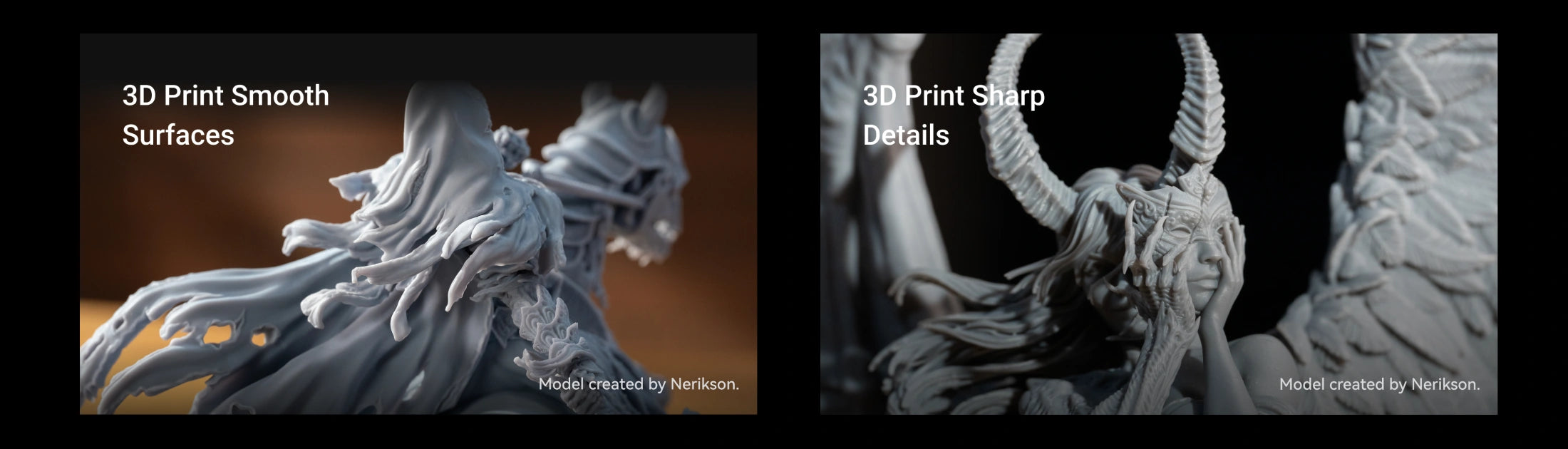

- 33μmの精度

- 自動樹脂レベル検出

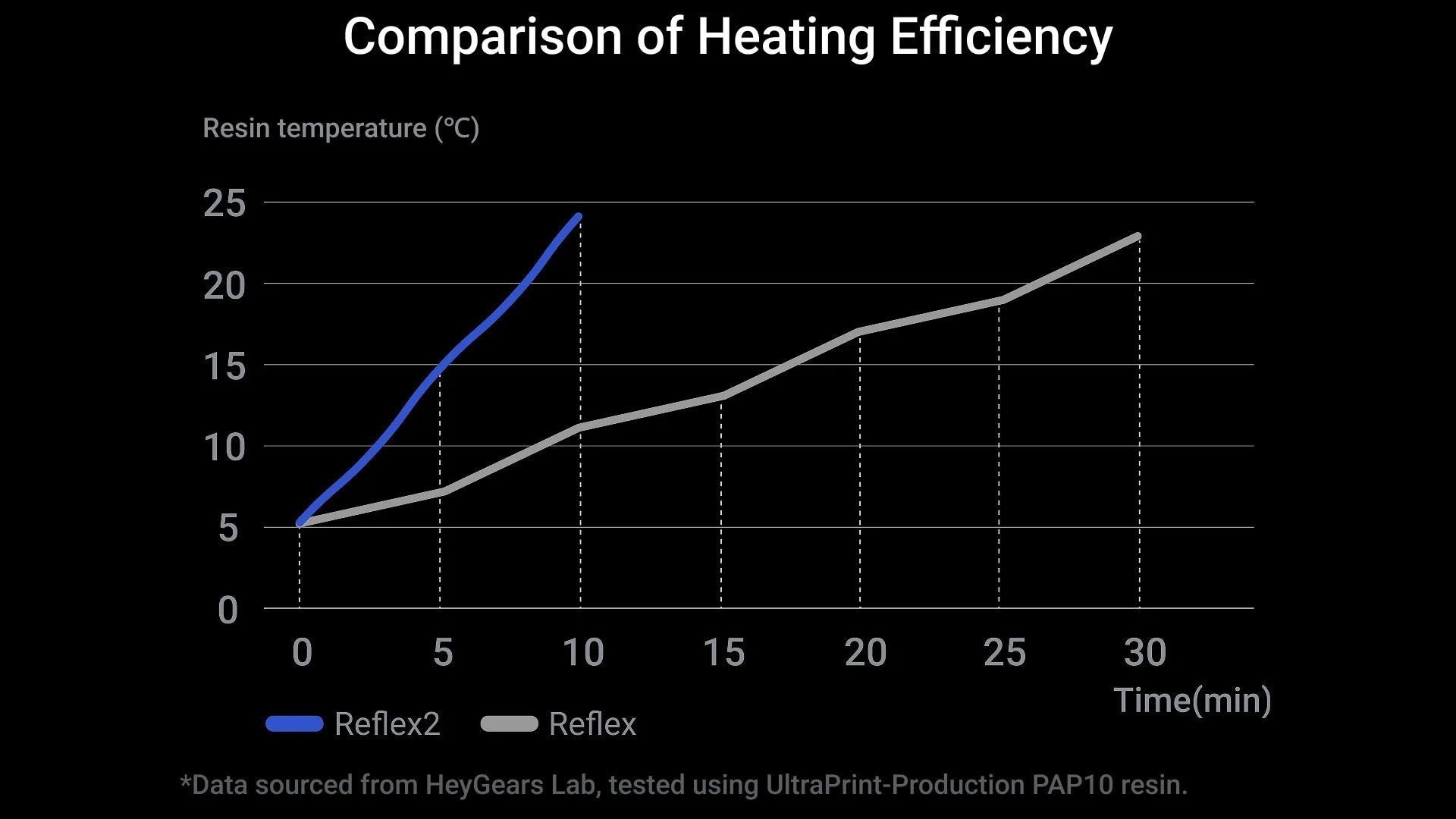

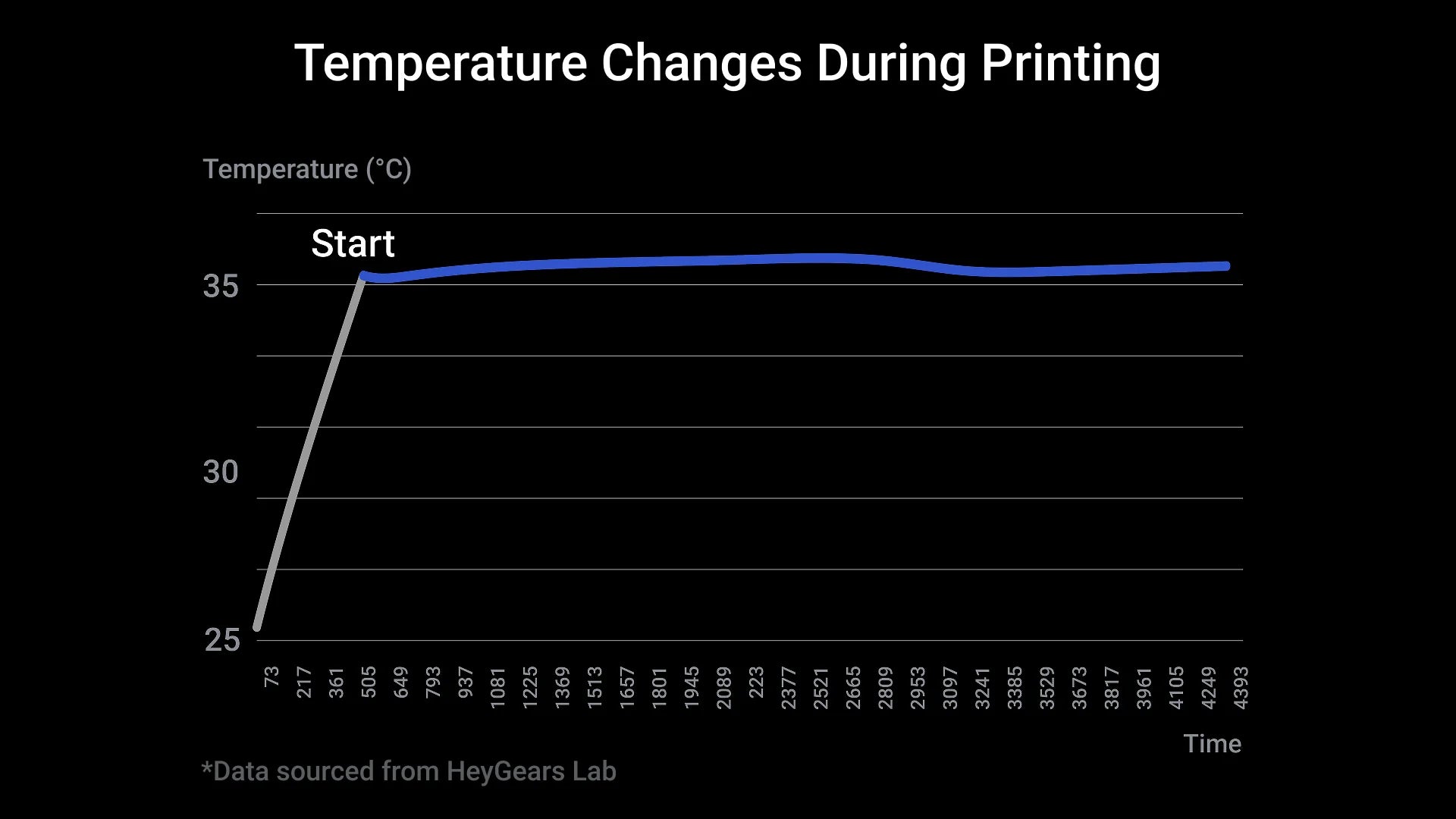

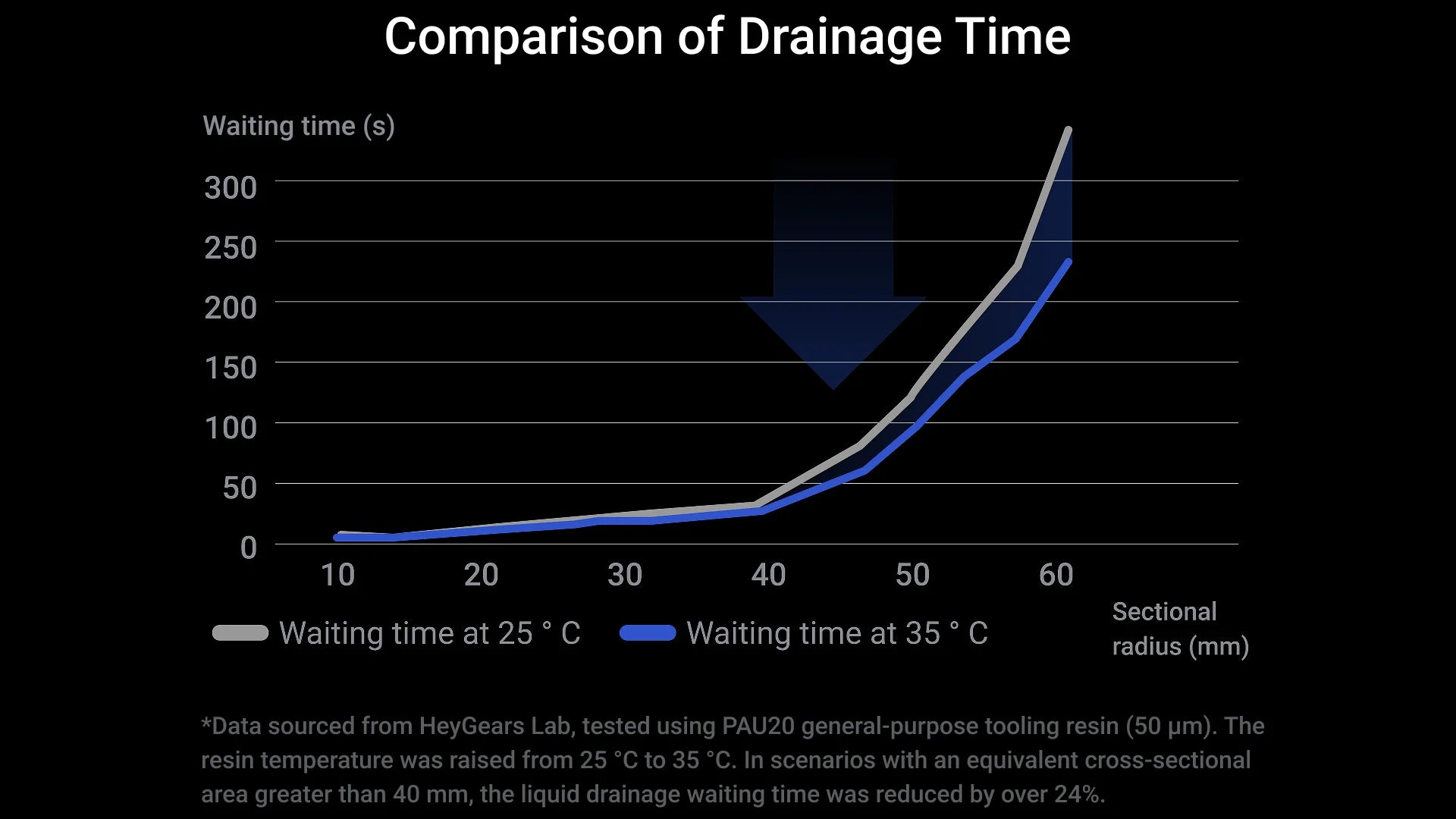

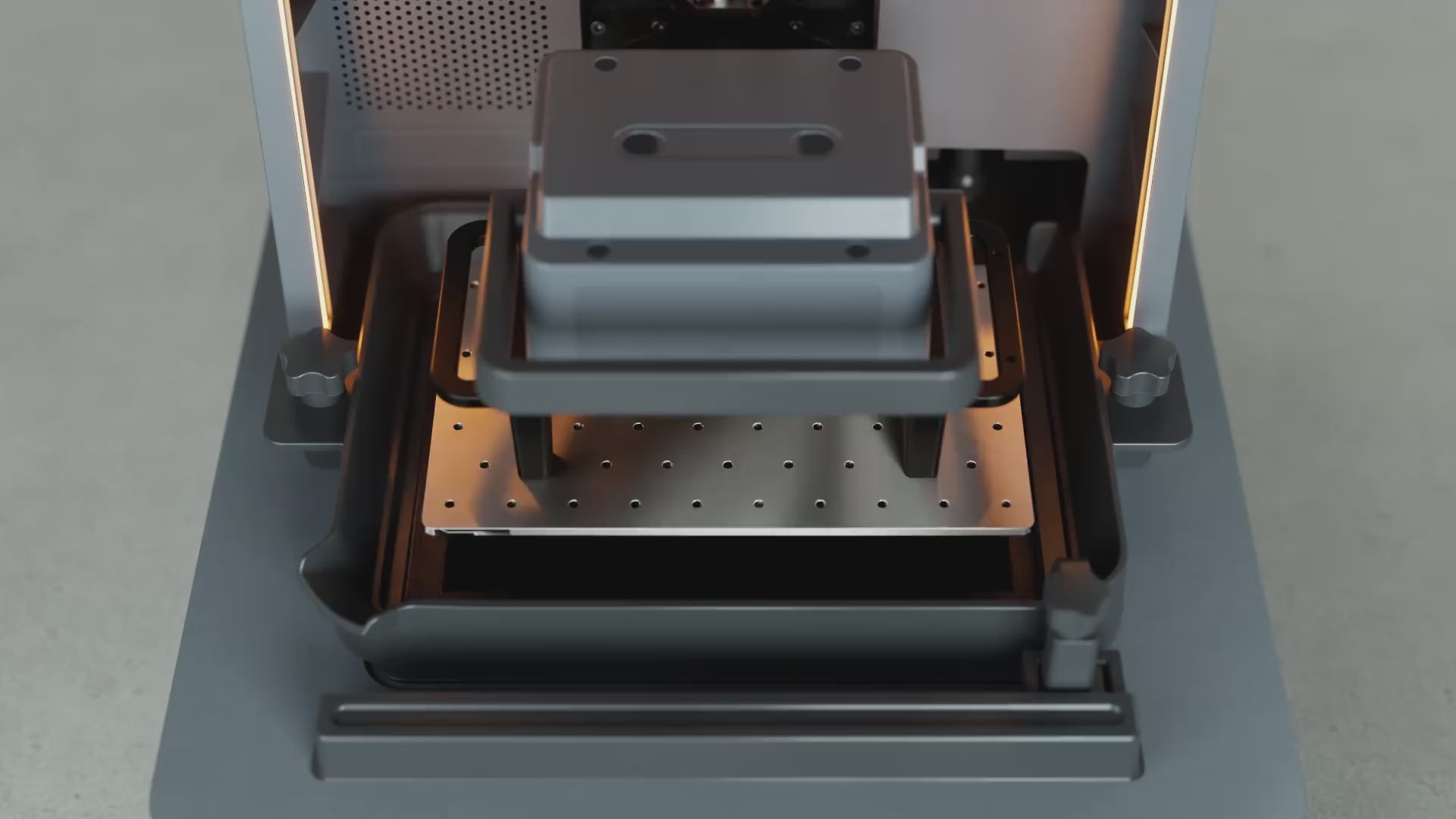

- 自動加熱トレイ

- 詳細復元率90.6%

- 90%の一貫性

Compatible Resins

Reflex 2 is currently compatible with these materials: PAC10, PAU11, PAH10 Black, PAT10, PARP10 Orange Clay, PAP10 Ash Grey, PAWR10, PAS10 Black, PAF10, PAS10 Pale Purple (using Pulsing Release Module 2), PAH270, PAT10, PAE10, PAU20.

Package Includes

Reflex 2:

Reflex 2 3D Printer x1

Reflex 2 Combo :

Reflex 2 3D Printer x1

Wash x1

Cure x1

Reflex 2 with Pulsing Release Module Kit :

Reflex 2 3D Printer x1

Pulsing Release Module 2 x1

Reflex 2 Heated & Pulsing Release Resin Tank x1

Pairs well with

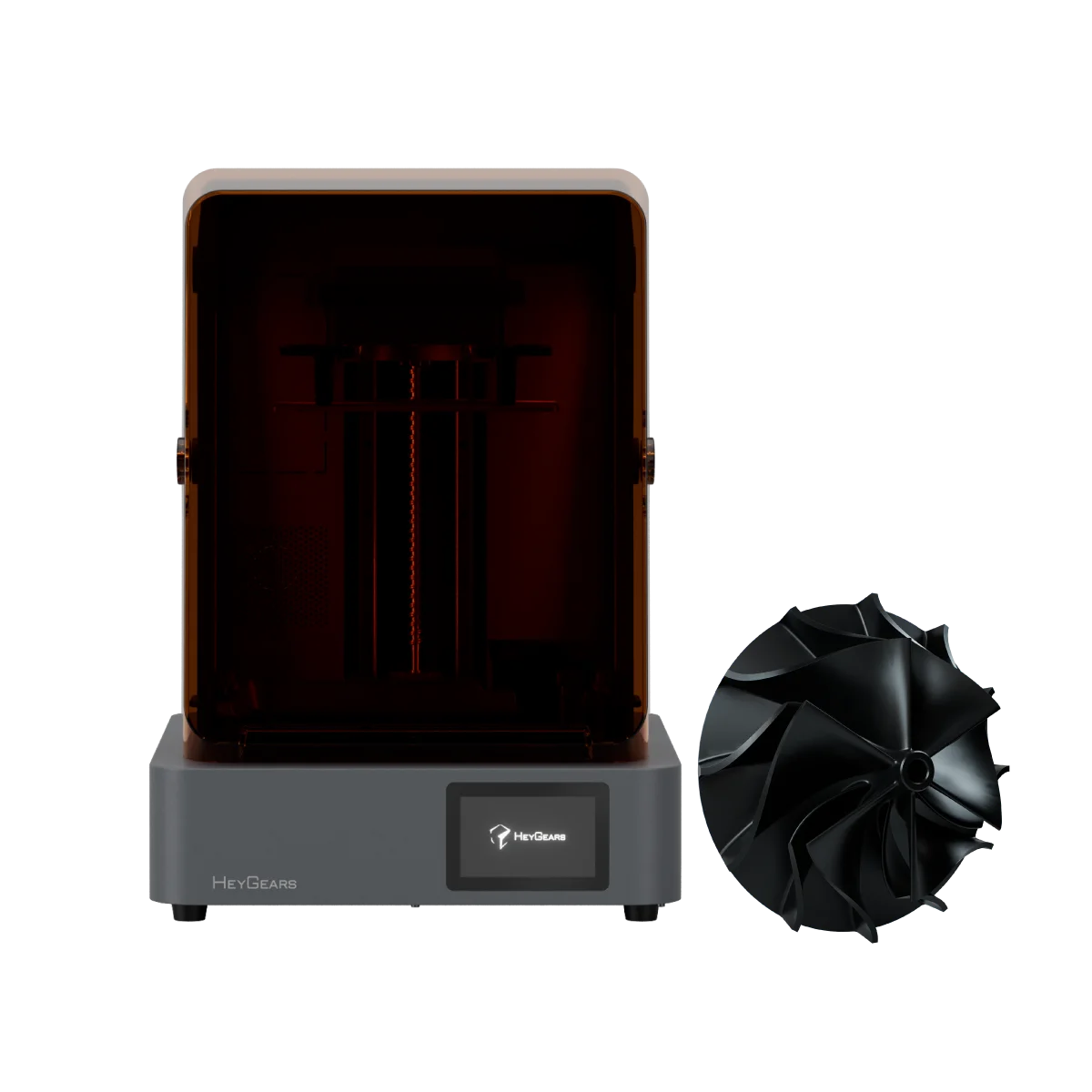

ウルトラクラフト リフレックス 3D プリンター

We're committed to providing you with the best service. Please don't hesitate to reach out if you have any questions.

-

Shipping Information

Free shipping on orders over $399. Click here for more shipping details.

-

Customer Support

Need assistance? We are here to help!

WhatsApp:

+1 949-283-2998(US)

Mon-Fri, 9AM-5PM PSTEmail Support:

contact@heygears.com

Technical Support:

customersupport@heygears.com

-

Get Started

Getting Started with Your HeyGears 3D Printer

-

FAQ’s

Please read our FAQs page to find out more.

Hear It From Our Users

Why Choose Reflex 2

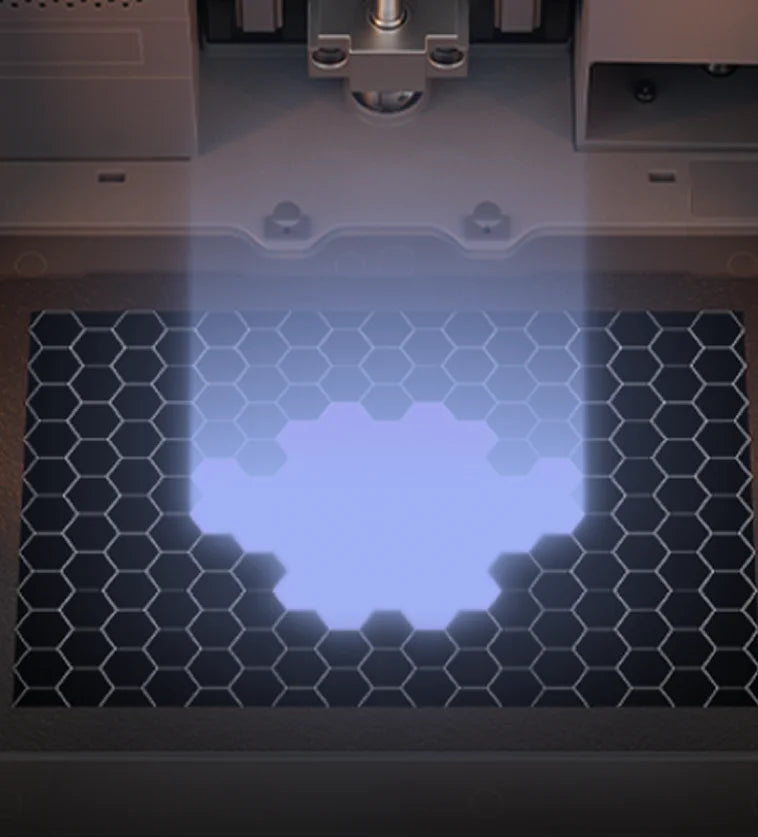

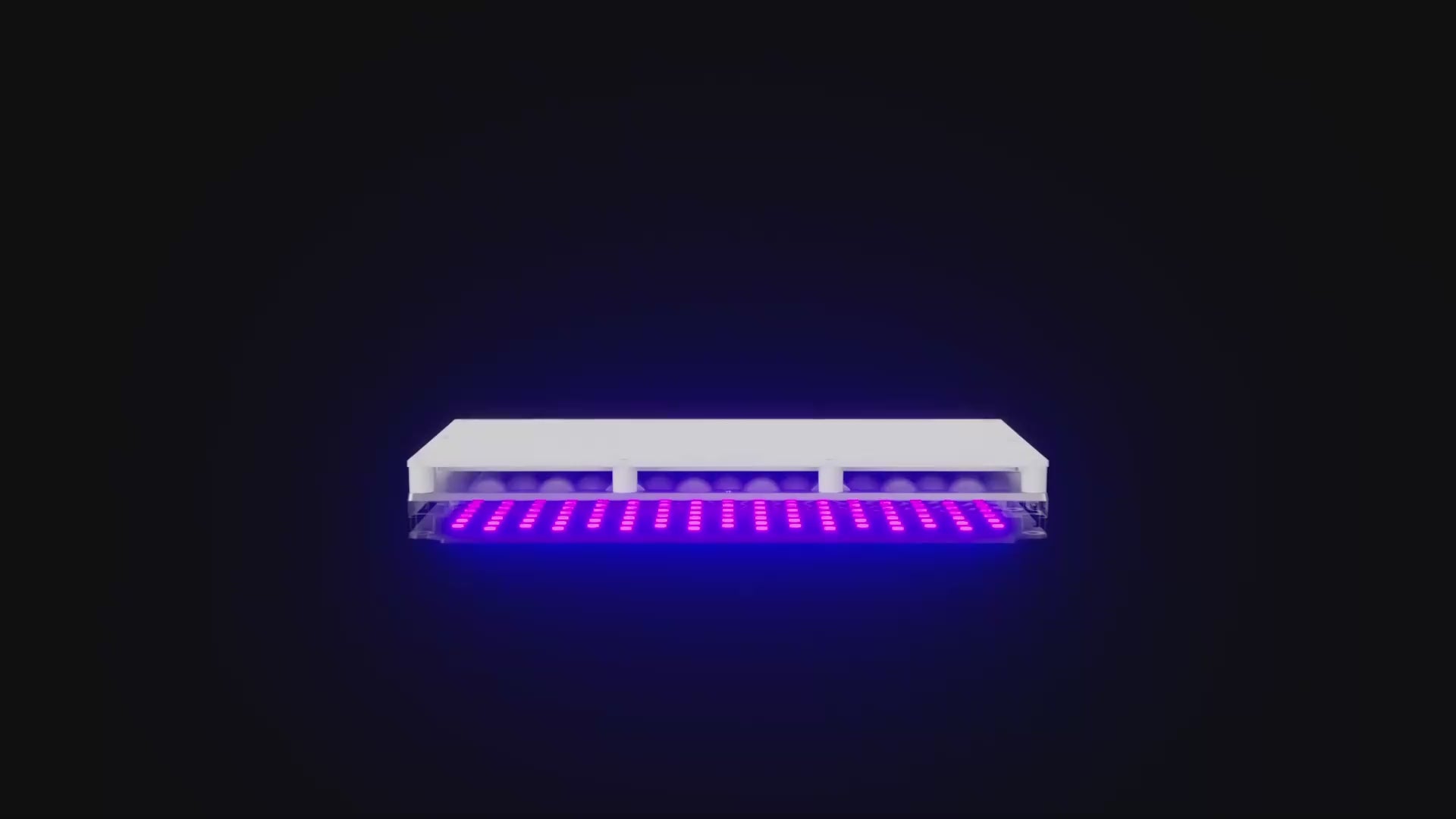

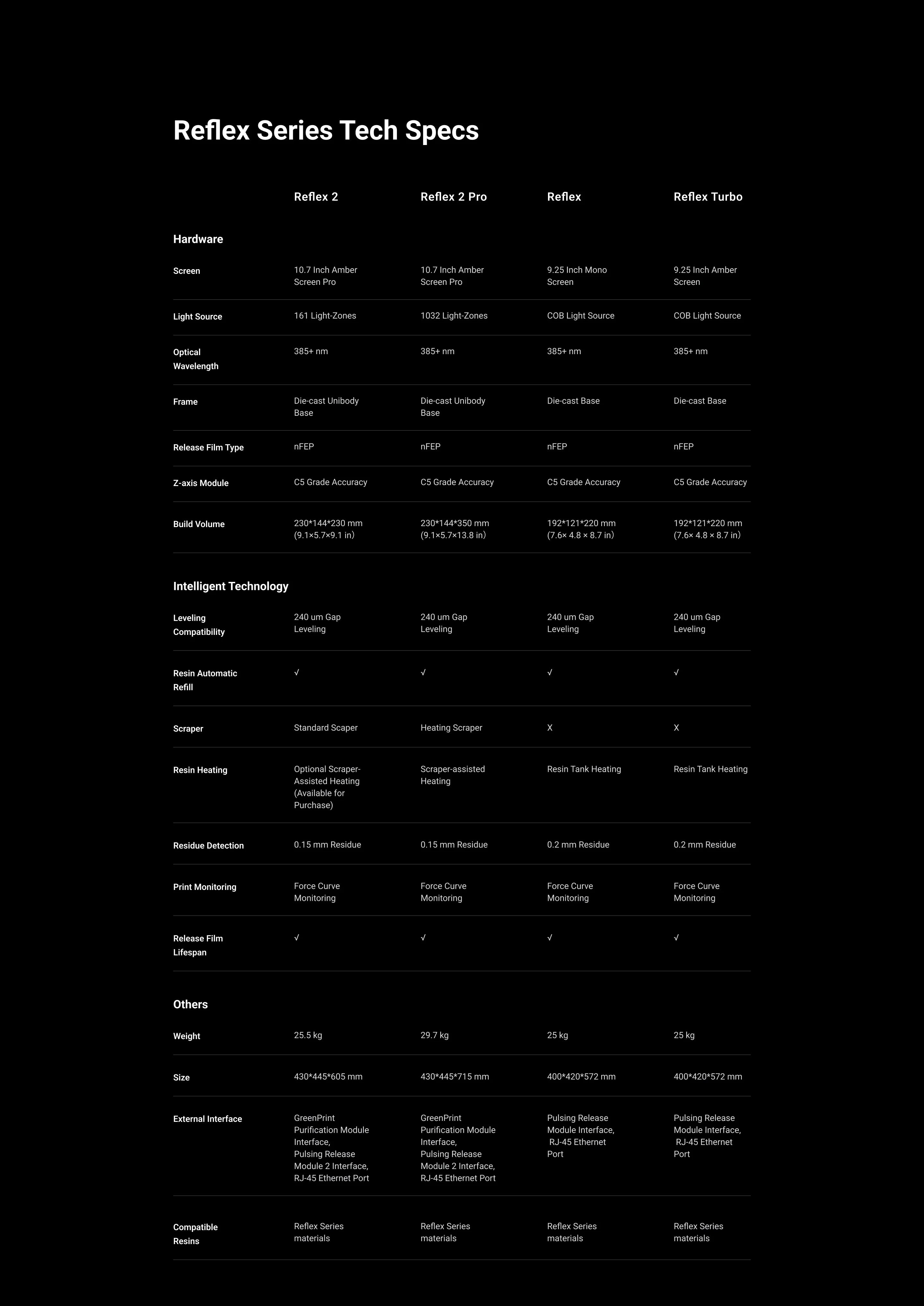

161 OptiZone Light Engine, Pioneered by HeyGears

AI-Powered 86,000+ Zone Light Calibration for Unmatched Light Uniformity

The upgraded visual calibration algorithm, MASK, uses 86,020 calibration zones to compensate for light intensity variations in each screen zone. This method achieves ≥94% light uniformity and print accuracy of ≤0.05 mm*.

*Data sourced from HeyGears Lab.

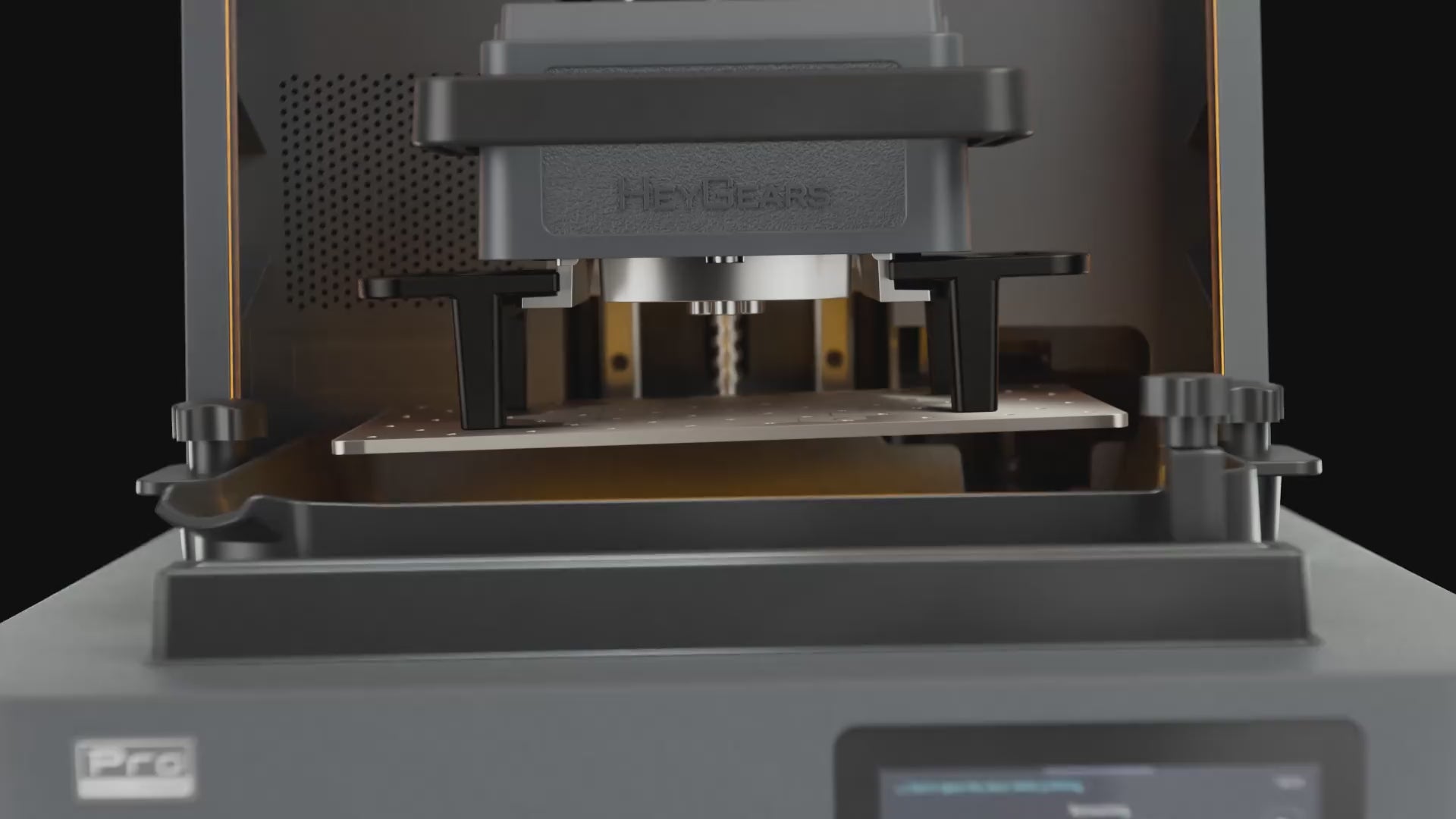

Enhanced 3D Printing Reliability

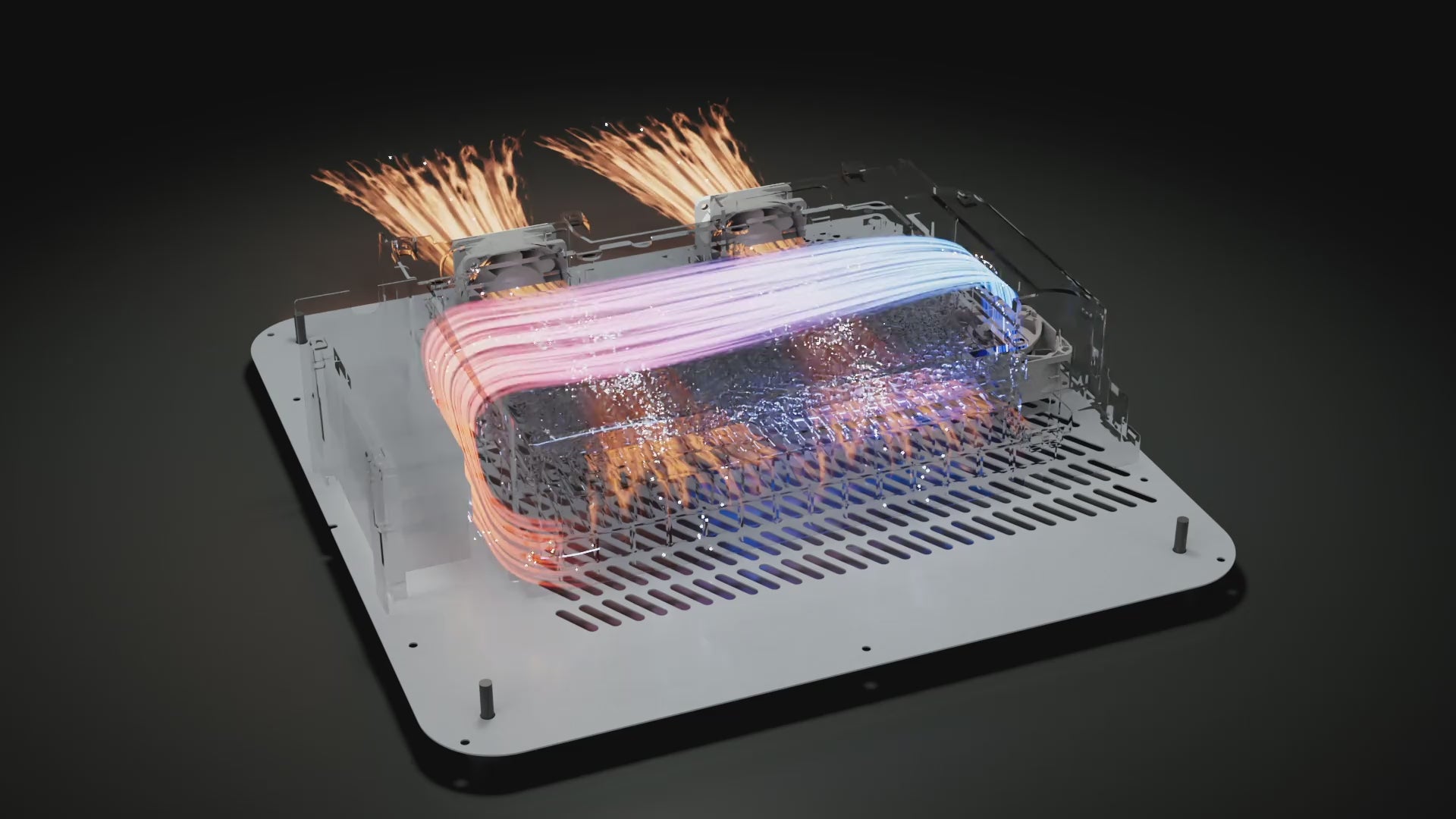

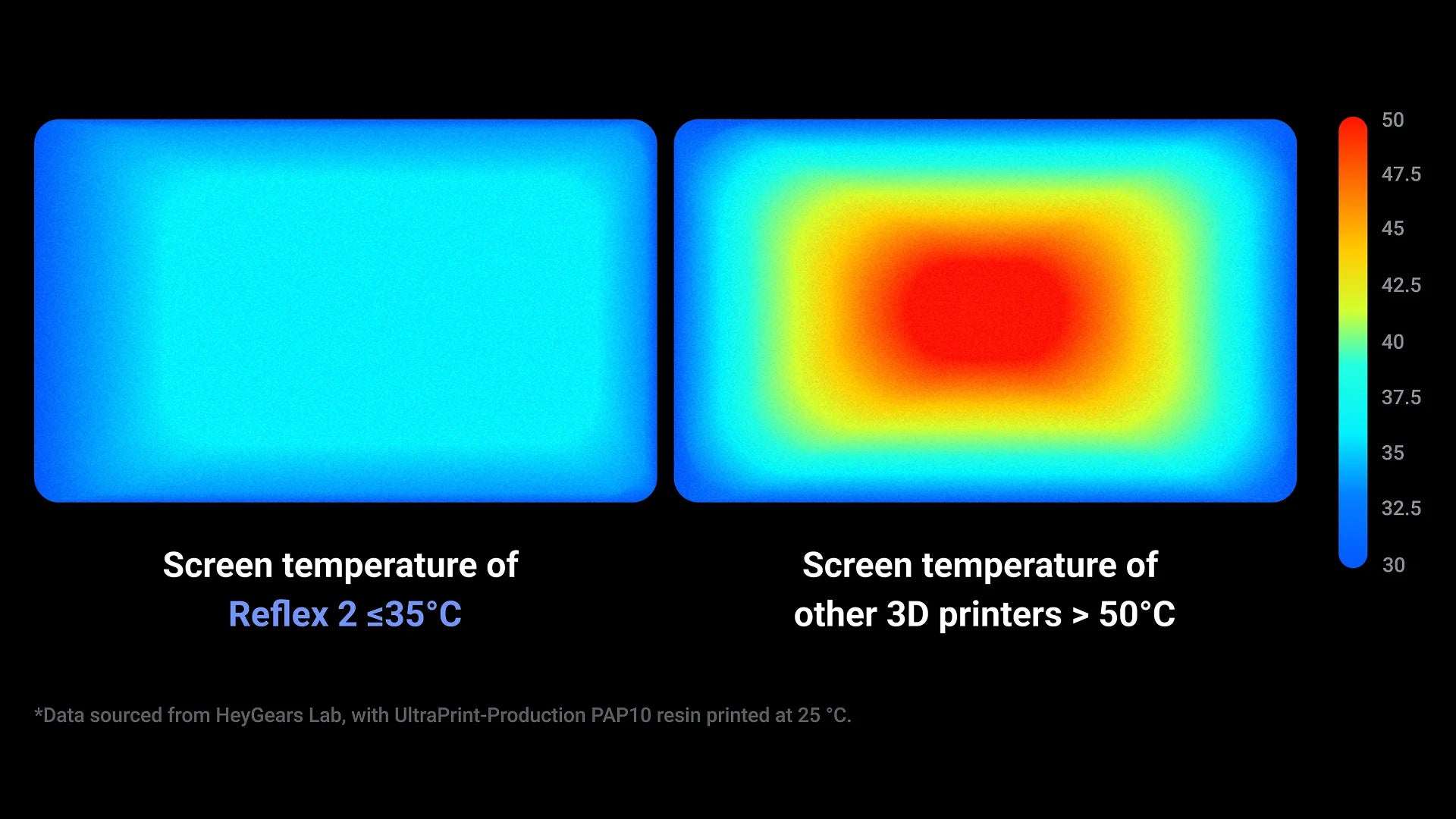

Intelligent Temperature Control

Specifications

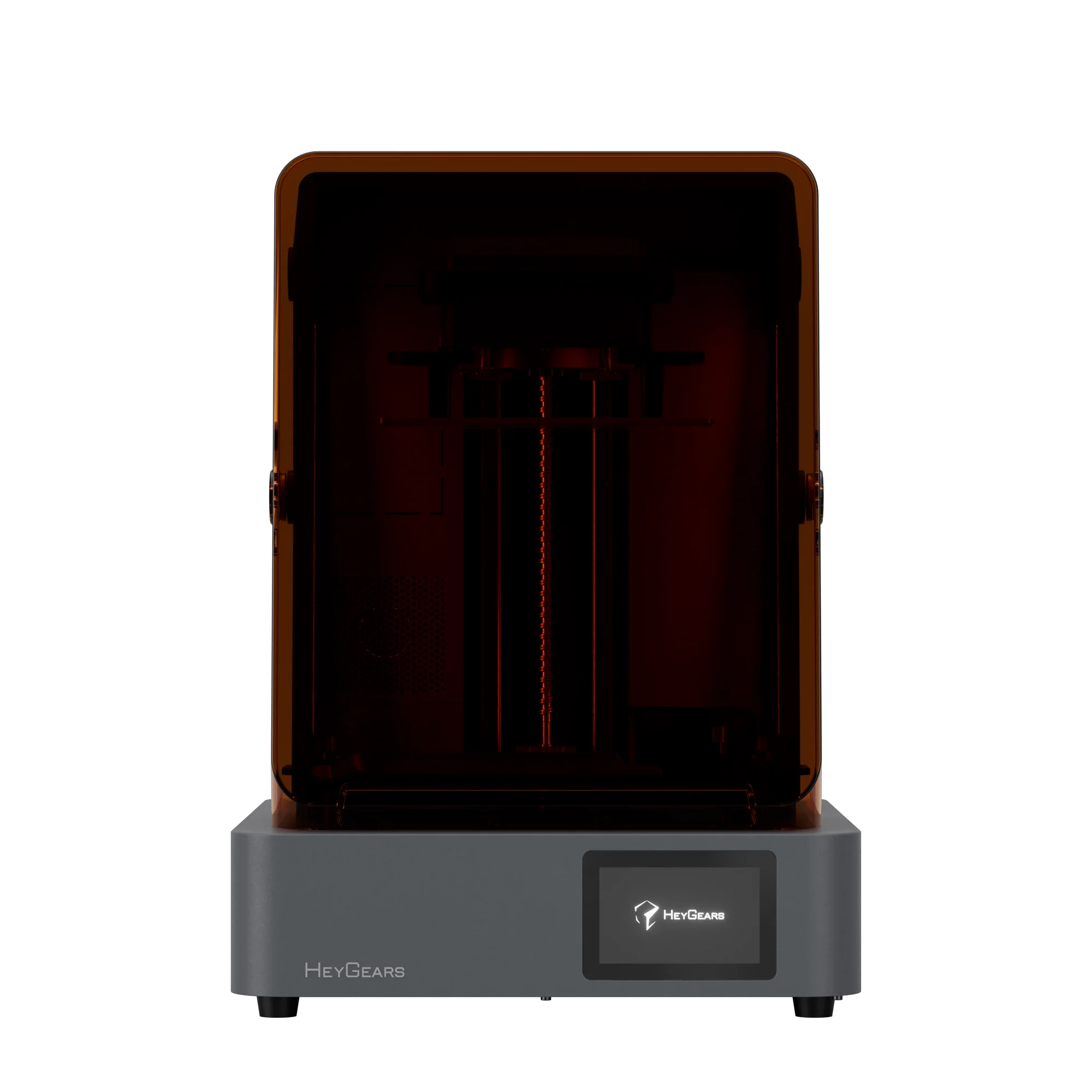

Product Name:

UltraCraft Rapid Production System

Product Model:

UltraCraft Reflex 2

Marketing Name

Reflex 2

3D Printing Technology:

LCD (MSLA)

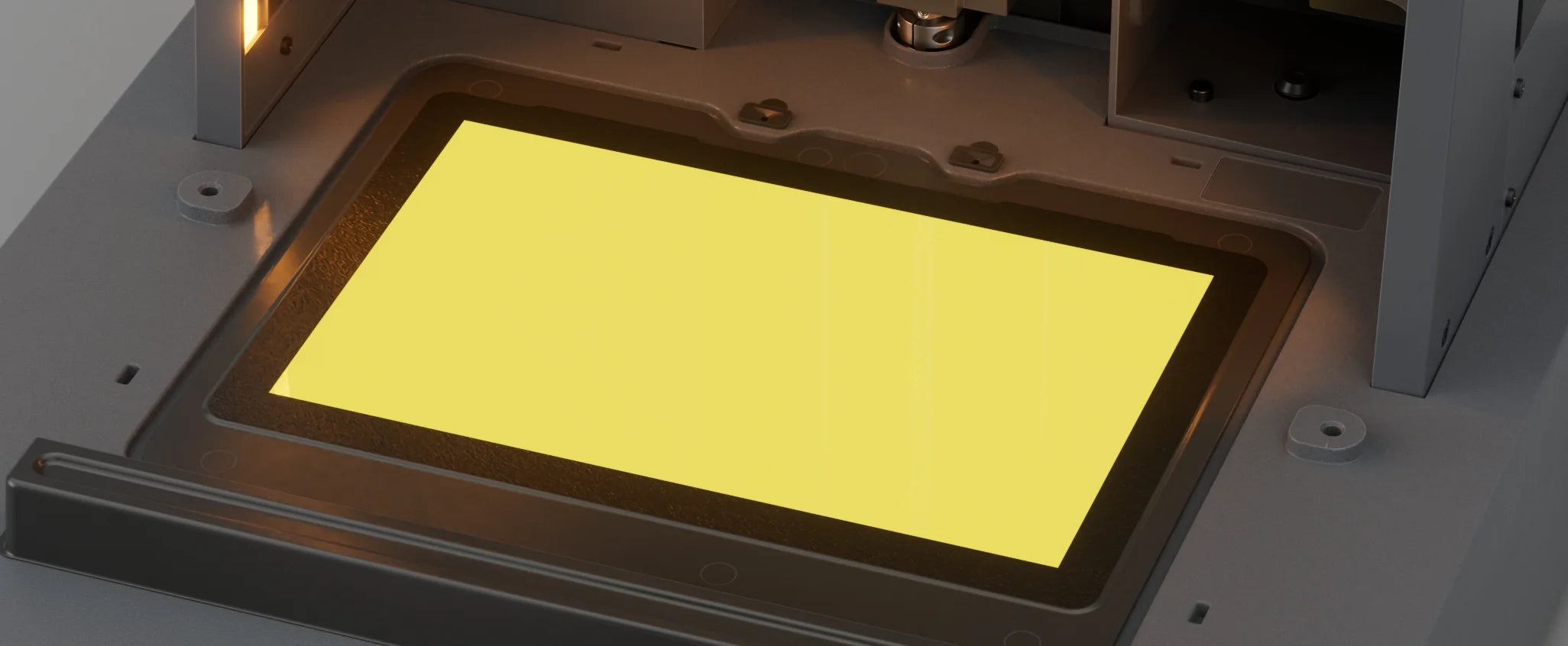

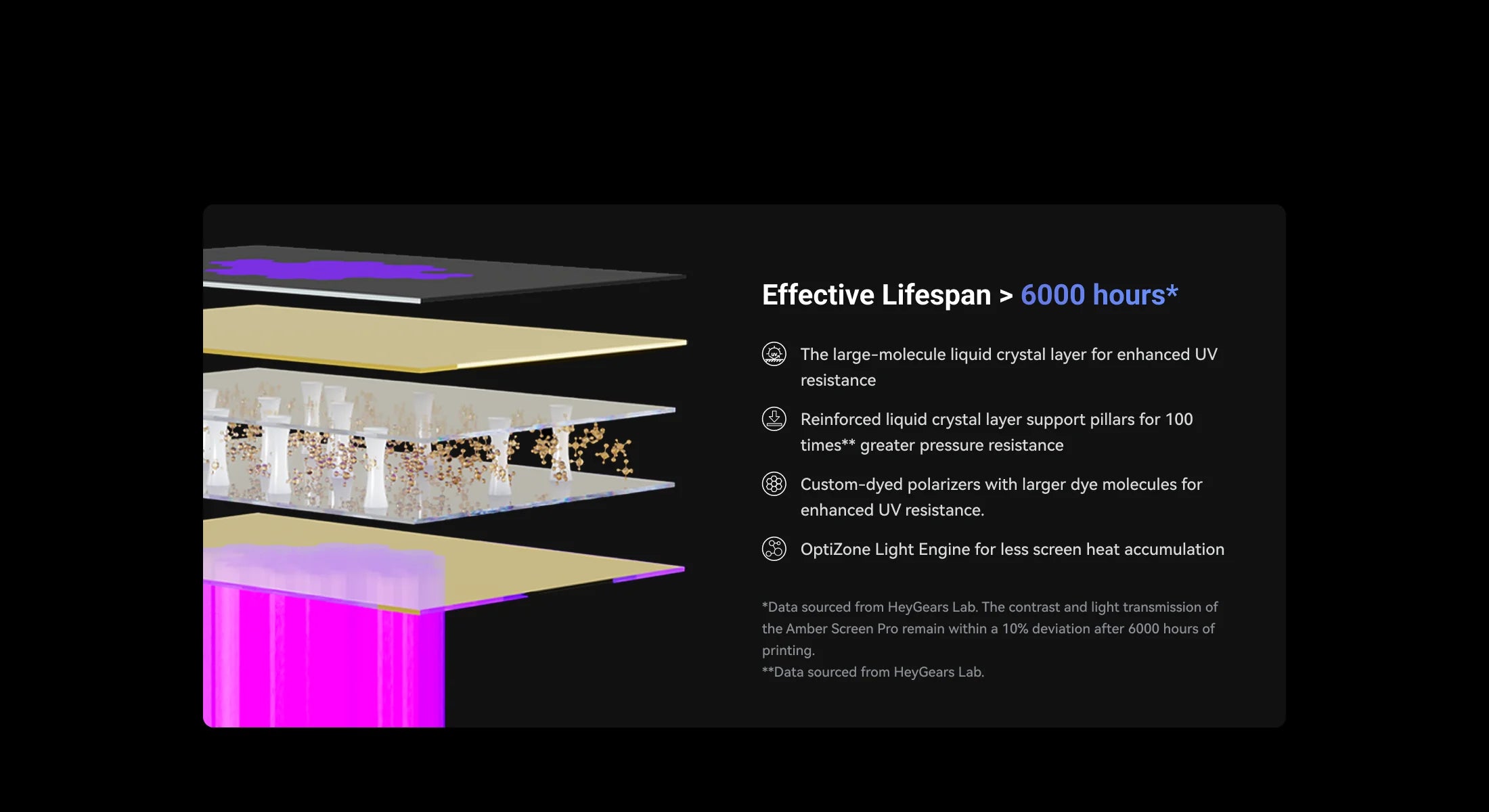

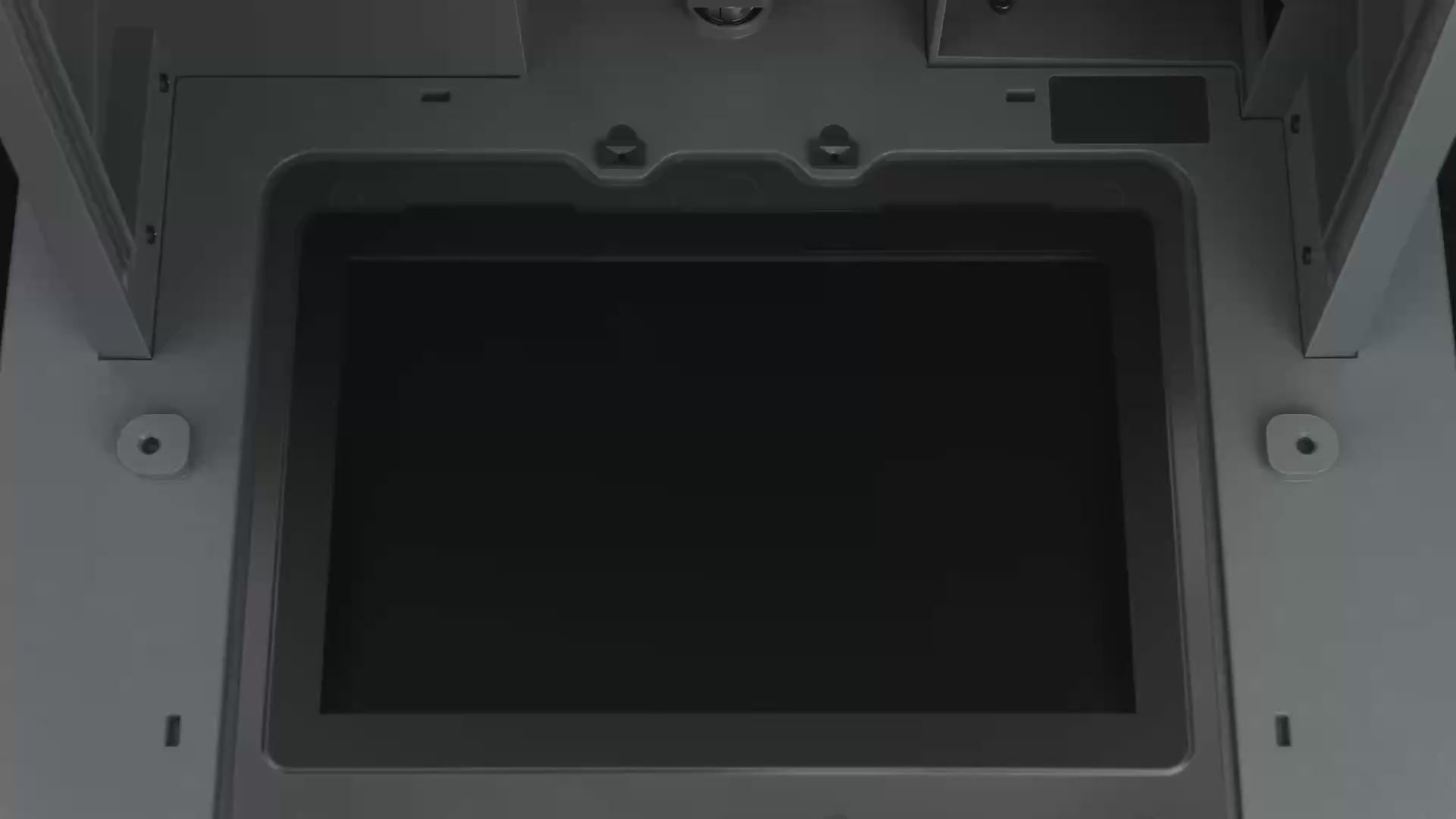

Screen:

10.7 Inch 6K Amber Screen Pro

Optical Wavelength:

385+ nm

Light Source:

161 Light-Zones

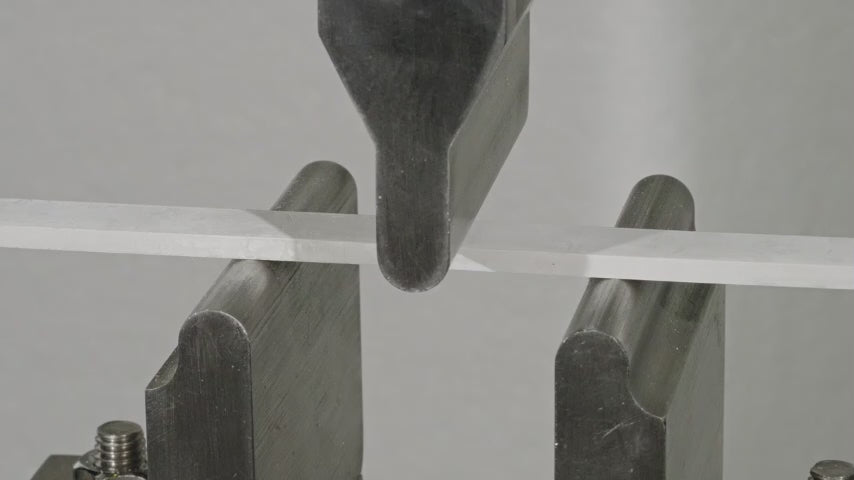

Z-axis Module:

C5 Grade Accuracy

Build Volume:

230×144 x 230 mm

(9.1×5.7×9.1 in)

XY Native Pixel:

40 μm

Accuracy:

±20 μm

Layer Thickness:

20-250 μm

Resin Heating:

Optional Scraper-Assisted Heating

(Available for Purchase)

Residue Detection:

0.15 mm Residue

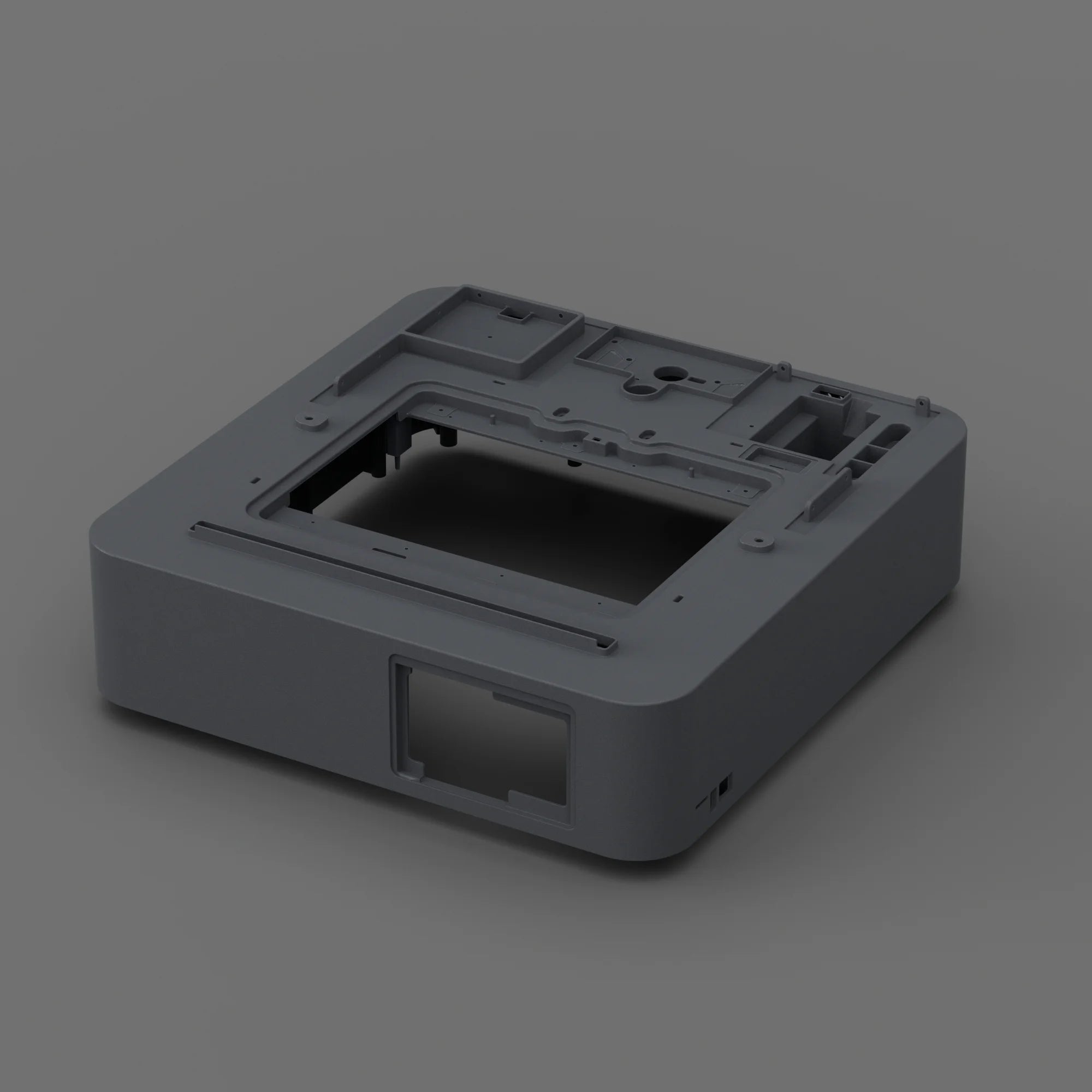

Frame:

Die-casted Unibody Base

Weight:

25.5 kg

Rated Power:

350 W

Voltage:

100-240 V~50/60 Hz

Size:

430*445*605 mm

External Interface:

• GreenPrint Purification Module Interface

•Pulsing Release Module 2 Interface

• RJ-45 Ethernet Port

Connectivity:

USB, WIFI, LAN

Language:

English, Simplified Chinese

Compatible Resin

Compatible with all Reflex Series materials

Included in the Box

Printer

Regular Scraper

Spatula

Power Cord

Part Removal Tool

Resin Tank

Build Platform

Resin-Refill Lid

T-Type Wrench

Quick Start

After-sales Service Guide