- Upgraded for More Precise Pulse Control

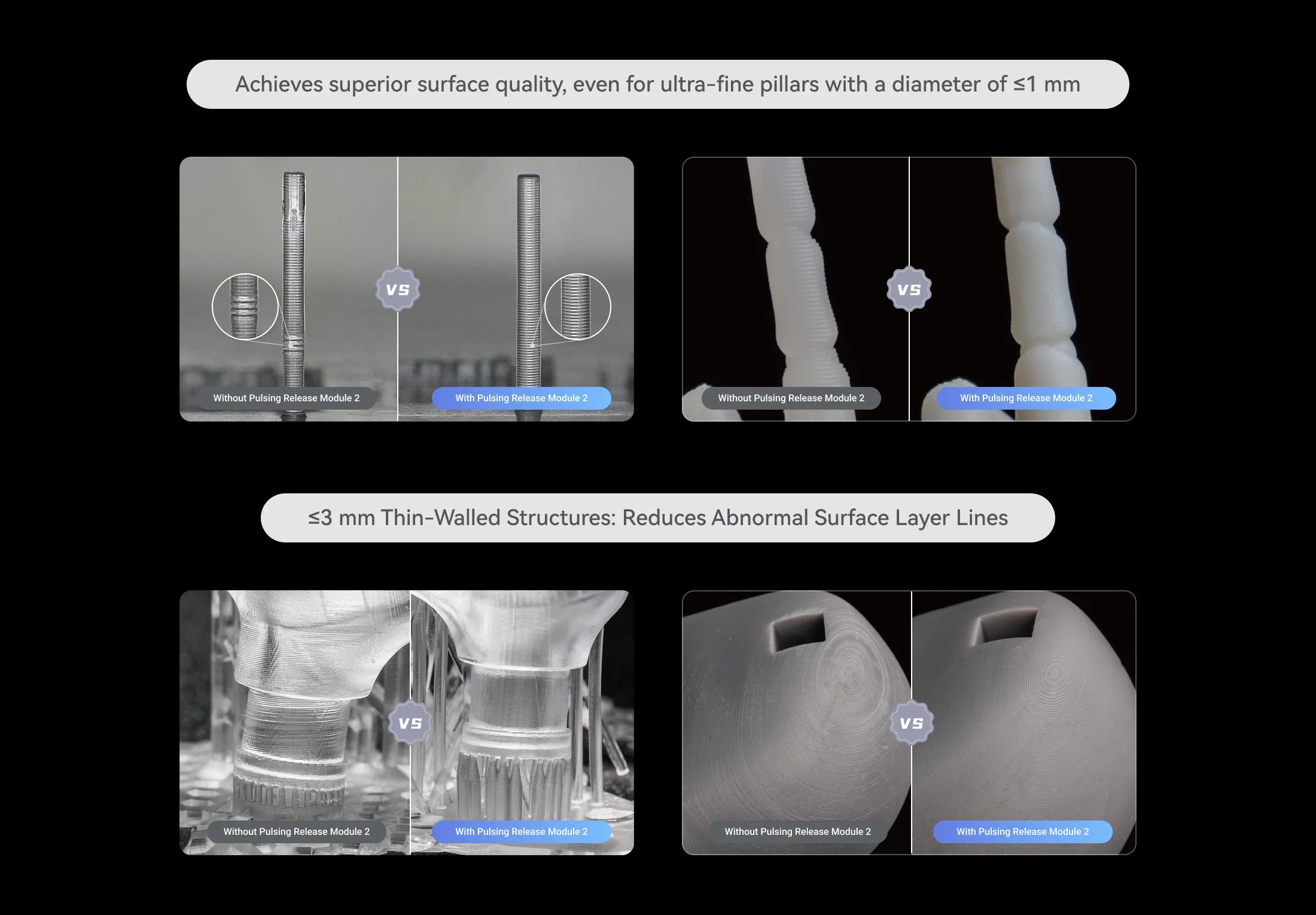

- ≤1 mm Ultra-fine Pillars with Better Surface Quality

- ≤3 mm Thin-Walled Structures with Reduced Abnormal Layer Lines

- More Extreme Support Parameters

- Up to 60% Less Support Usage

- Up to 54% Reduction in Support Contact Point Area

- Resins that must use PRM 2: PAC10, PAE10, PAU20

- Resins not compatible with PRM 2: PAWW10 & PAWW20

Compatible with the Following 3D Printers:

- Reflex 2 3D Printer

- Reflex 2 Pro 3D Printer

Pairs well with

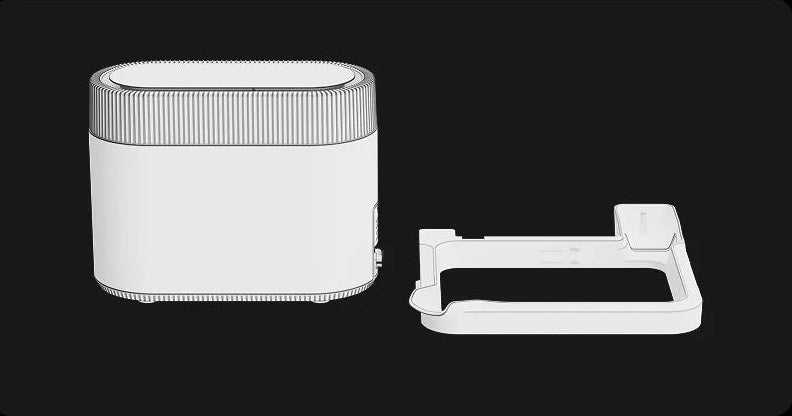

Pulsing Release Module 2 Kit

We're committed to providing you with the best service. Please don't hesitate to reach out if you have any questions.

-

Shipping Information

Free shipping on orders over $399. Click here for more shipping details.

-

Customer Support

Need assistance? We are here to help!

WhatsApp:

+1 949-283-2998(US)

Mon-Fri, 9AM-5PM PSTEmail Support:

contact@heygears.com

Technical Support:

customersupport@heygears.com

-

Get Started

Getting Started with Your HeyGears 3D Printer

-

FAQ’s

Please read our FAQs page to find out more.

Upgraded for More Advanced Pulse Control

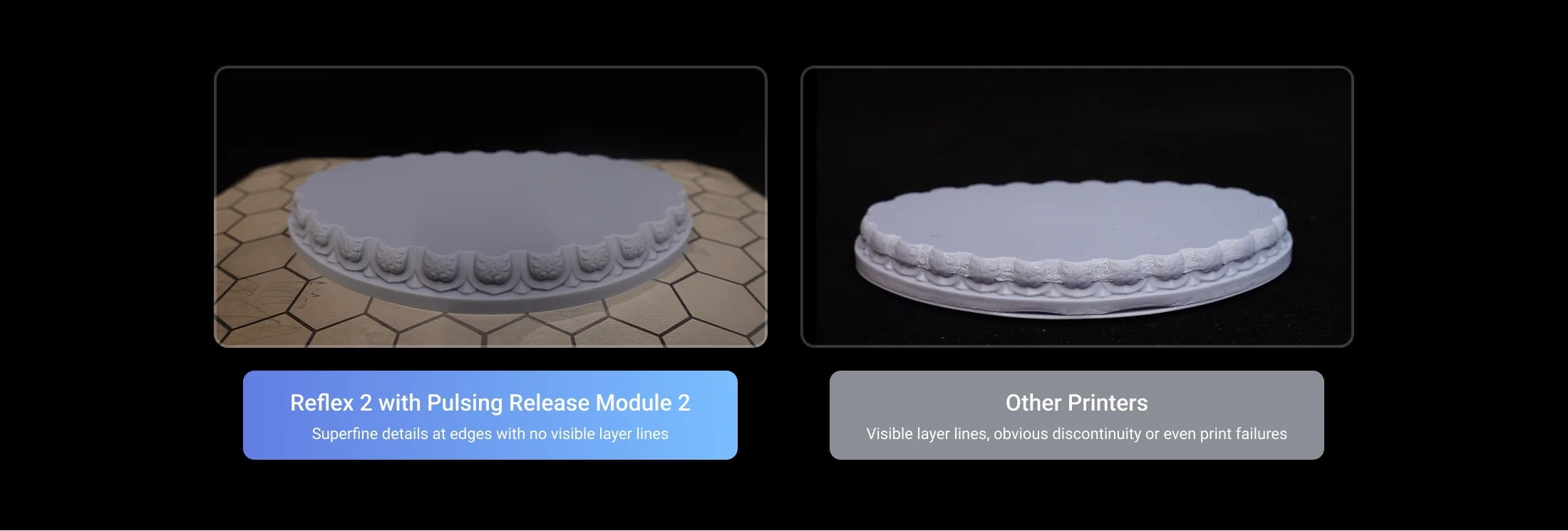

Improved Surface Quality for Precise Details

Large-format Parts

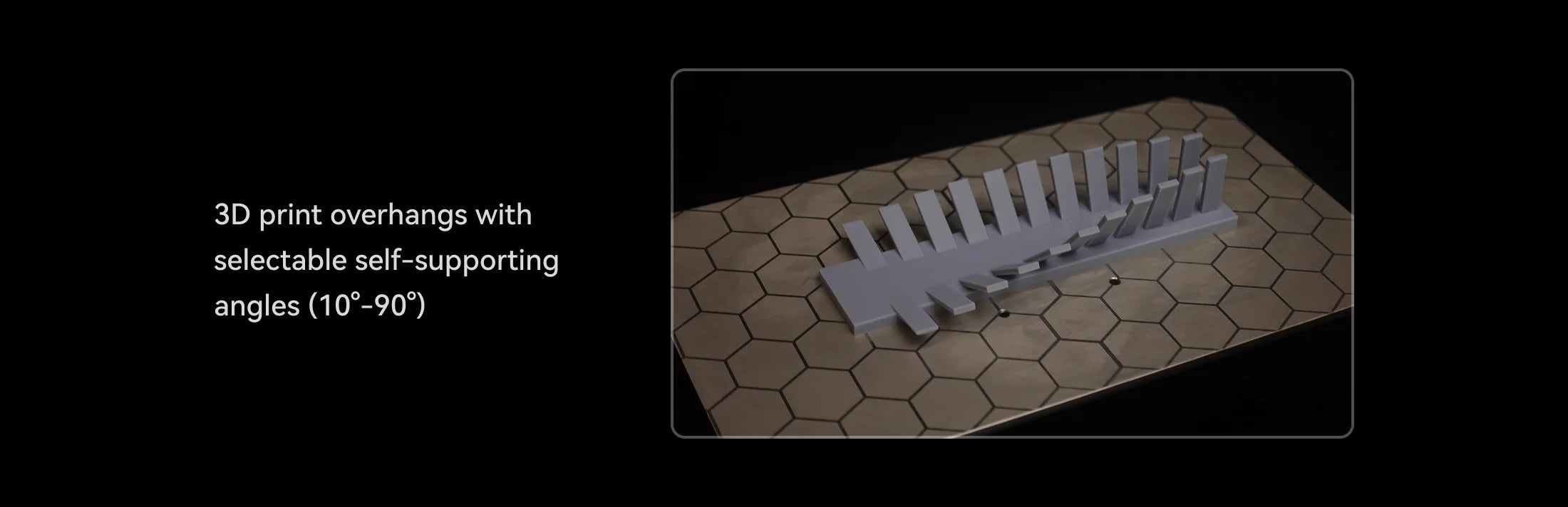

Self-supporting Complex Structures

Less Support Waste, Faster Post-processing

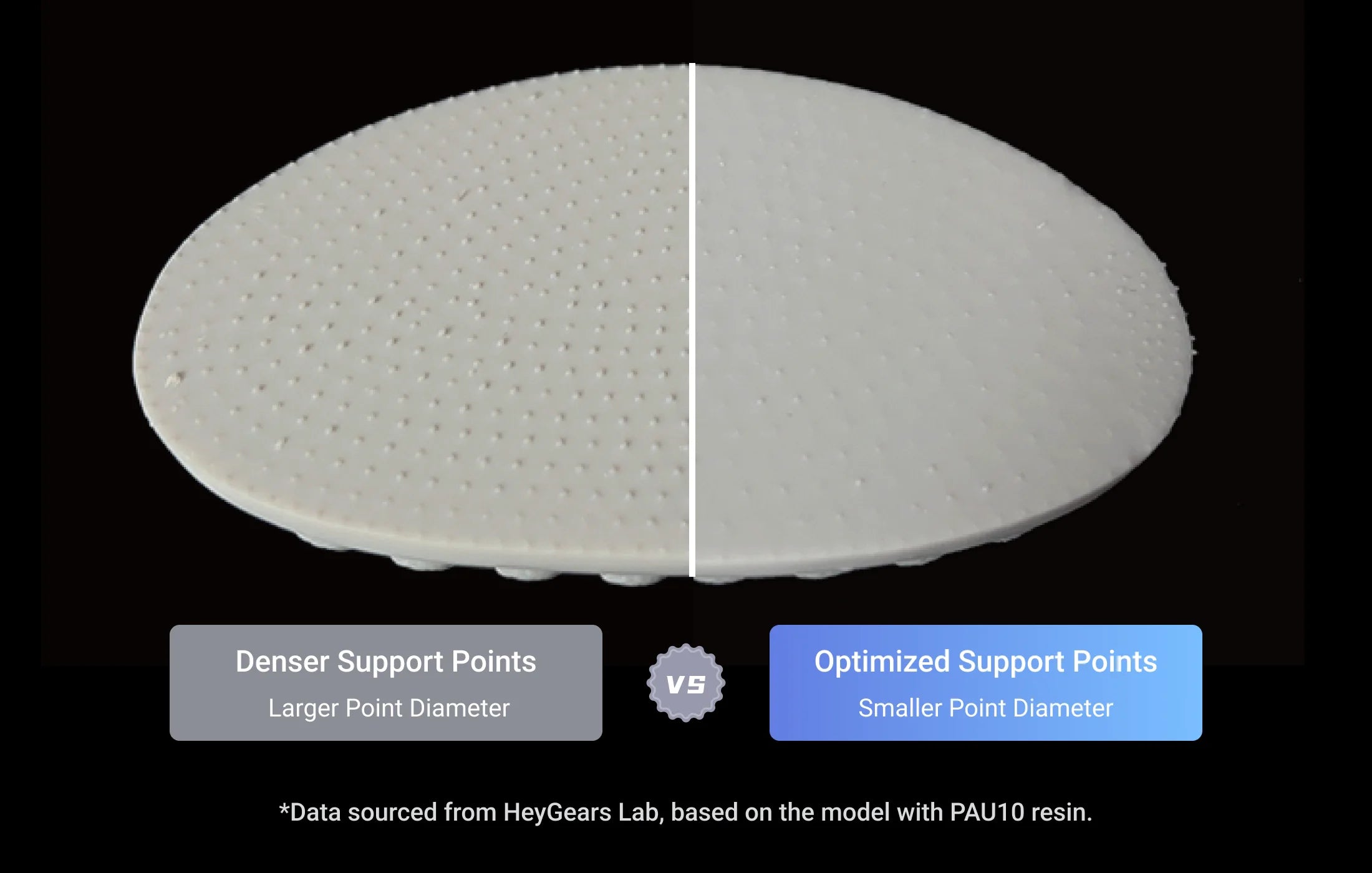

25%~54% Less Time Needed for Sanding or Polishing

The total area of support contact points has been reduced by 25% to 54%*, resulting in a decrease in the time needed for sanding or polishing.

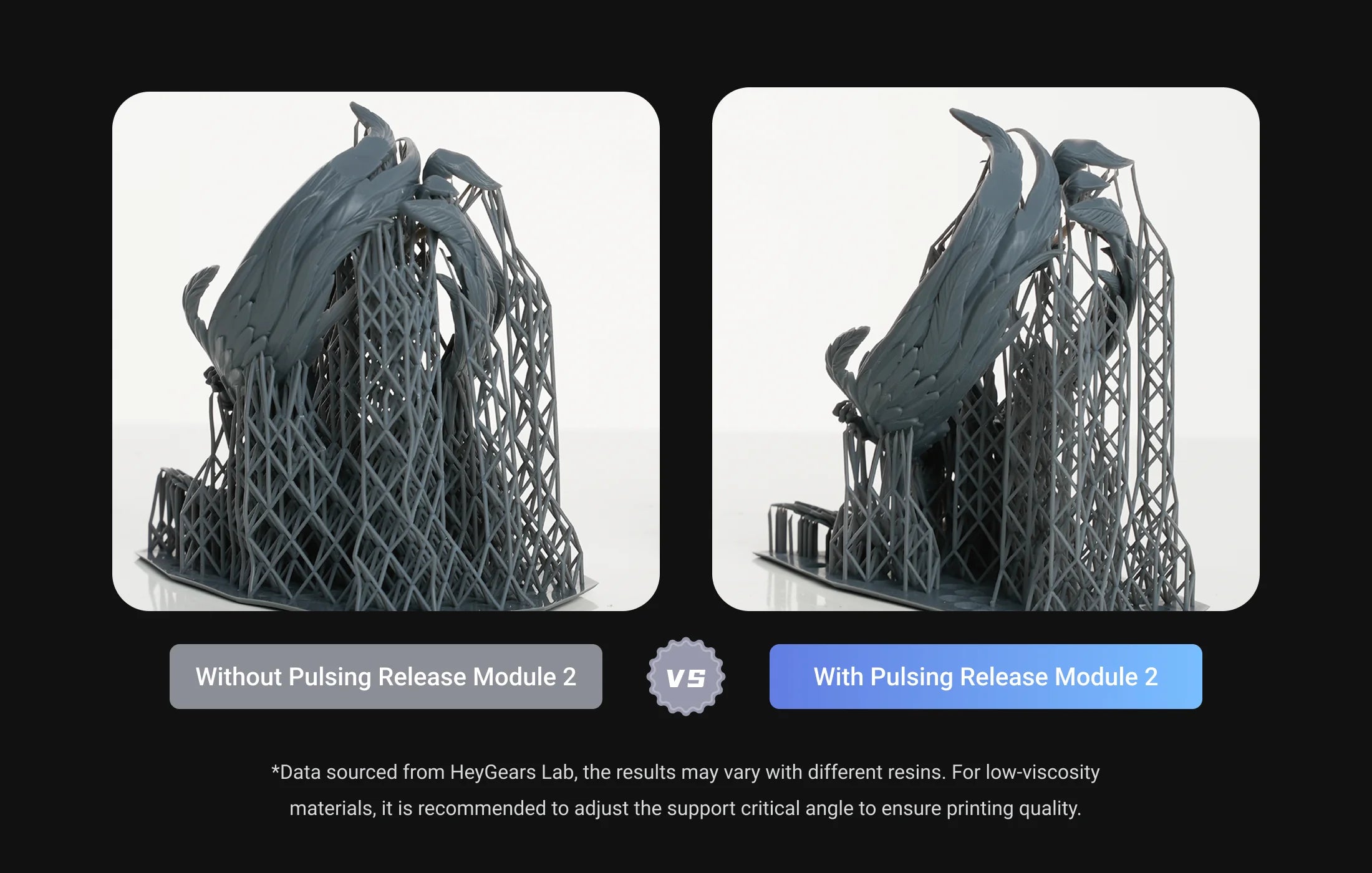

20% - 60% Fewer Supports

A lower peeling force reduces the demand for supports. As a result, support material usage is cut by 20%-60%* while ensuring successful prints, improving resin utilization.

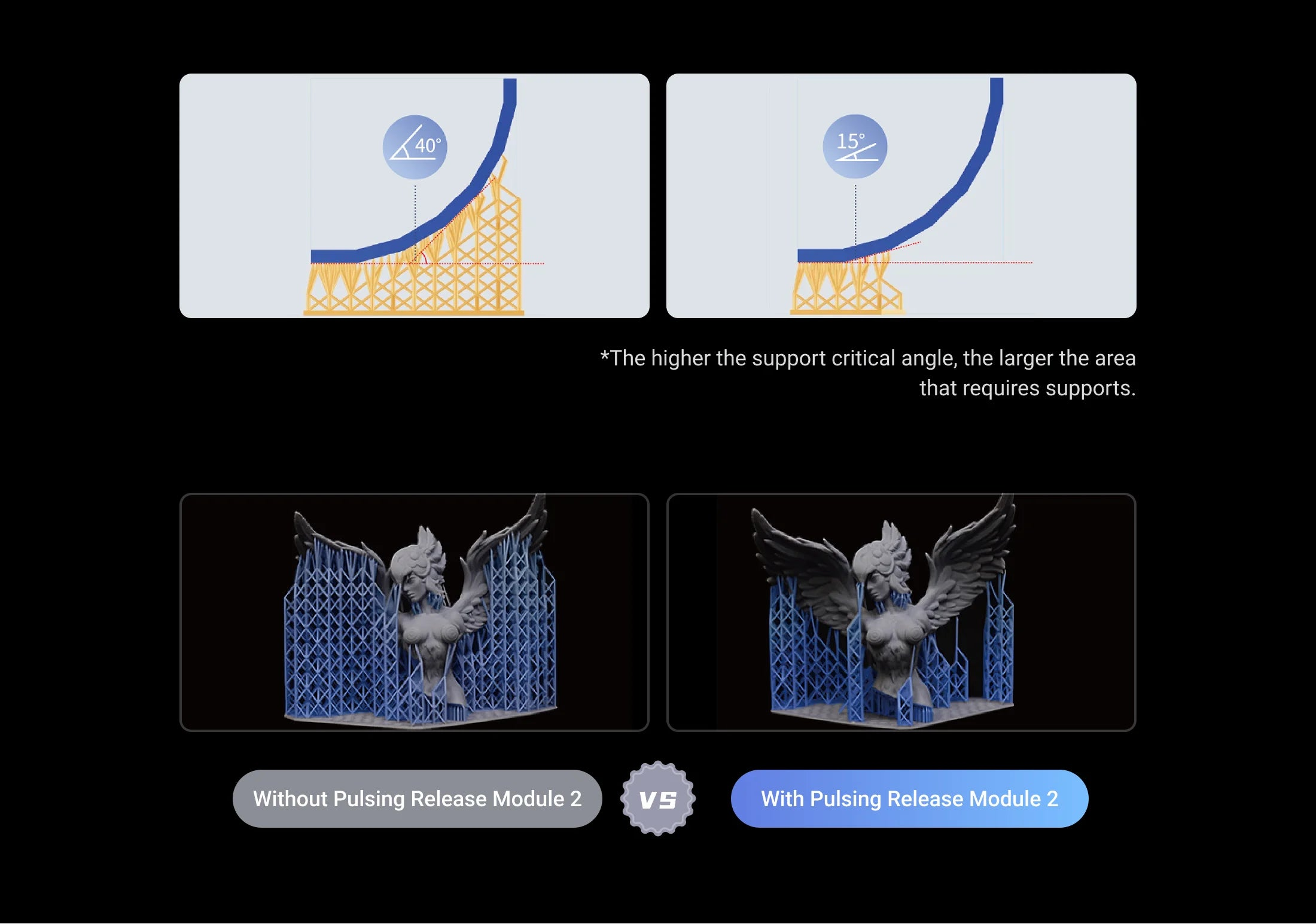

*Data sourced from HeyGears Lab, the results may vary with different resins. For low-viscosity materials, it is recommended to adjust the support critical angle to ensure printing quality.

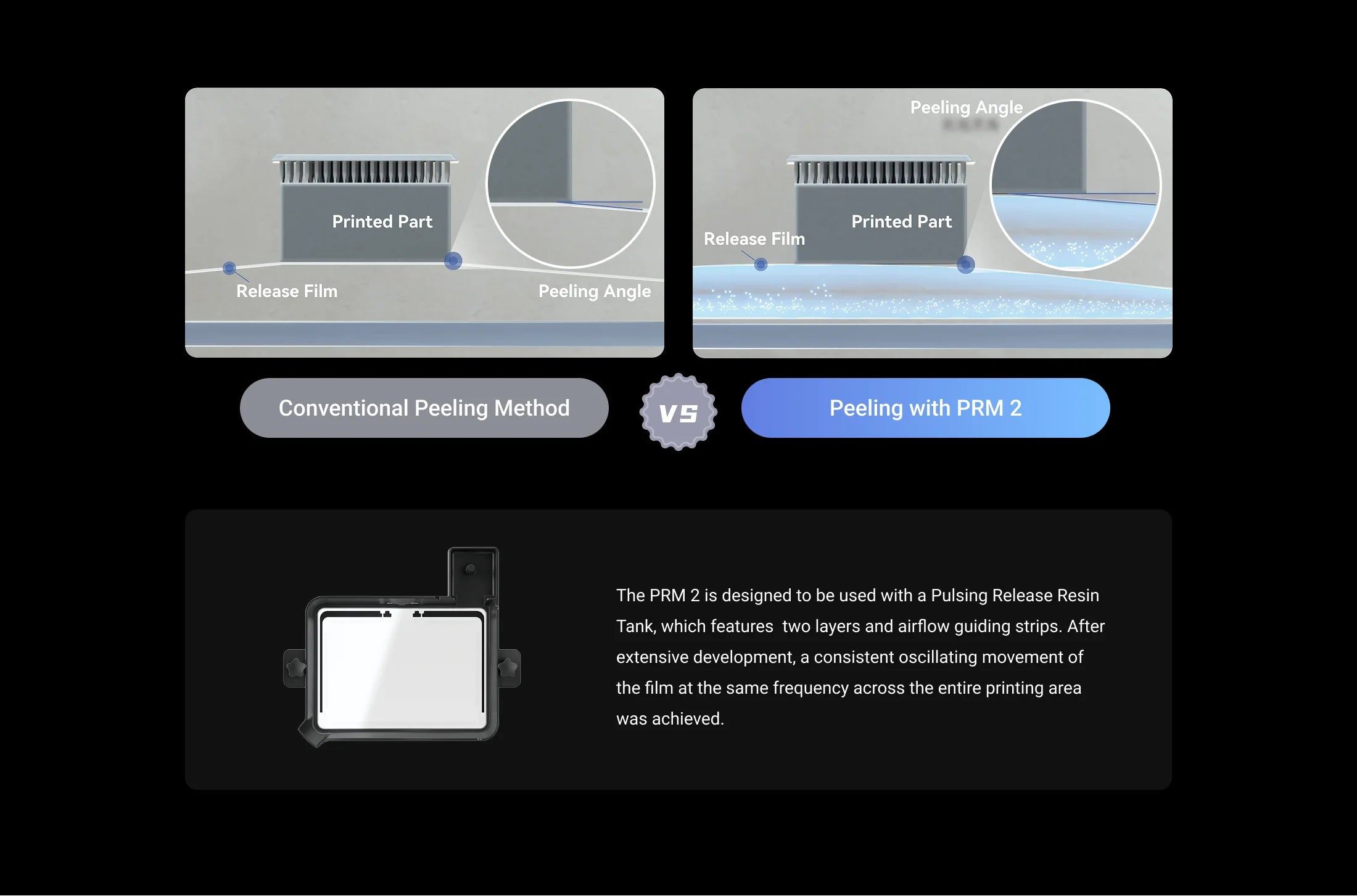

Reduced Peeling Force, Enhanced Print Results

How it Works

During the printing process, the PRM 2 creates a cycle of positive and negative pressure within the release film with periodic inflation and deflation.

This creates a larger peeling angle, reducing the force needed to separate the printedpart from the release film.

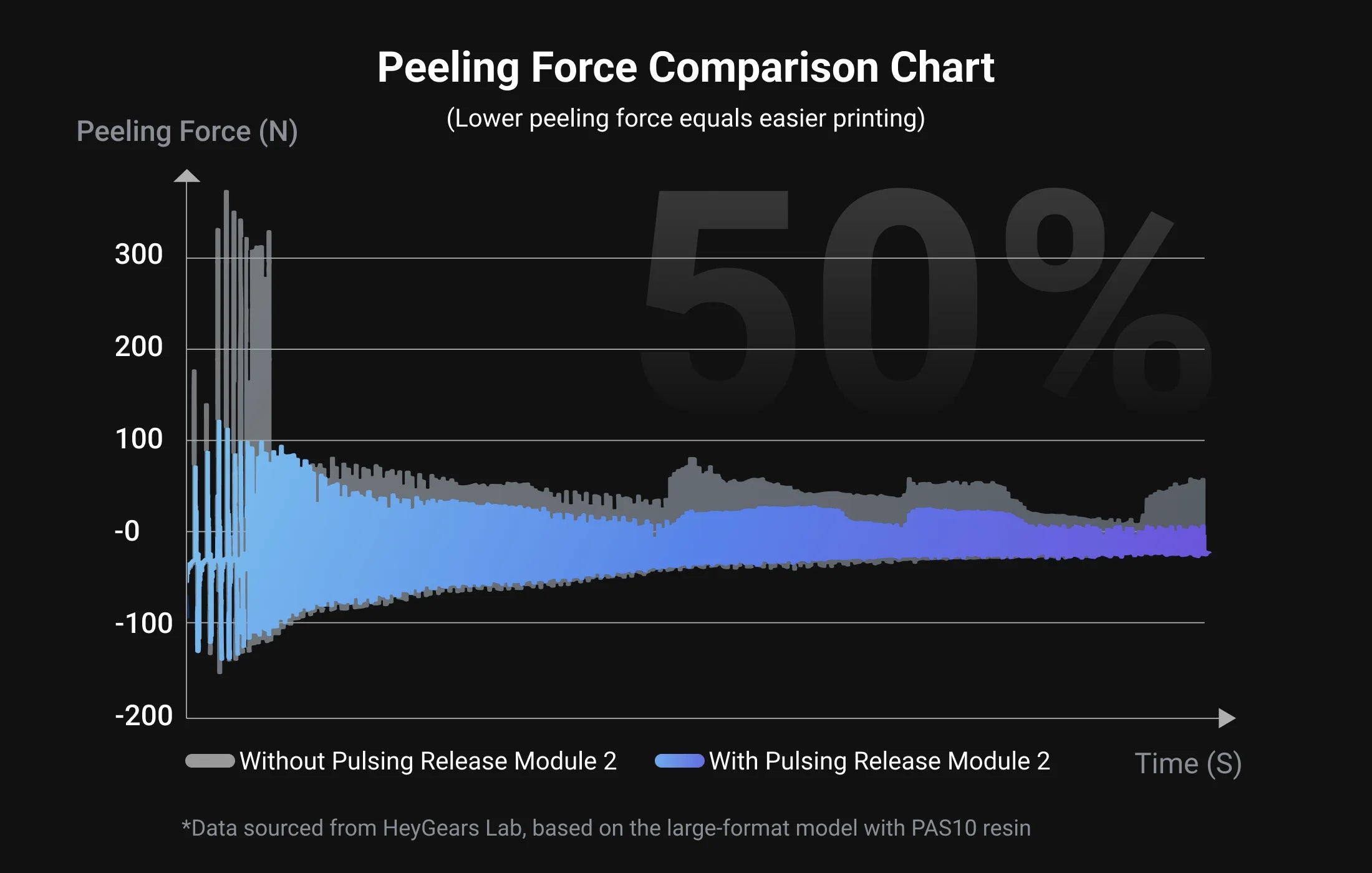

Reduce Peeling Force by Approximately 50%*

The Reflex 2 series, combined with the Pulsing Release Module 2, achieves a dramatic reduction in peeling force—by about 50%*.

This not only minimizes the need for support optimization but also breaks through the limits of manual tuning, ensuring a comprehensive improvement in final print quality.

*Data sourced from HeyGears Lab, based on the large-format model with PAS10 resin

Successful Prints With a Support Critical Angle as low as 15°

The reduction in peeling force allows for a lower critical support angle, which minimizes the number of supports and the area of support contact points, thereby streamlining the post-processing workflow.

Push the Boundaries of Your Support Settings

The reduction in peeling force allows for more extreme support parameters: the diameter of the support contact point can be reduced by up to 30%*, achieving up to a 70%* reduction in the area of the support contact point.

Specifications

- Input Voltage: 24V DC

- Rated Power: 25 W

- Dimensions: 310*148*235 mm 310*148*235 mm (12.52*35.83*39.25 in)

- Weight: 3 kg