Printer Highlights

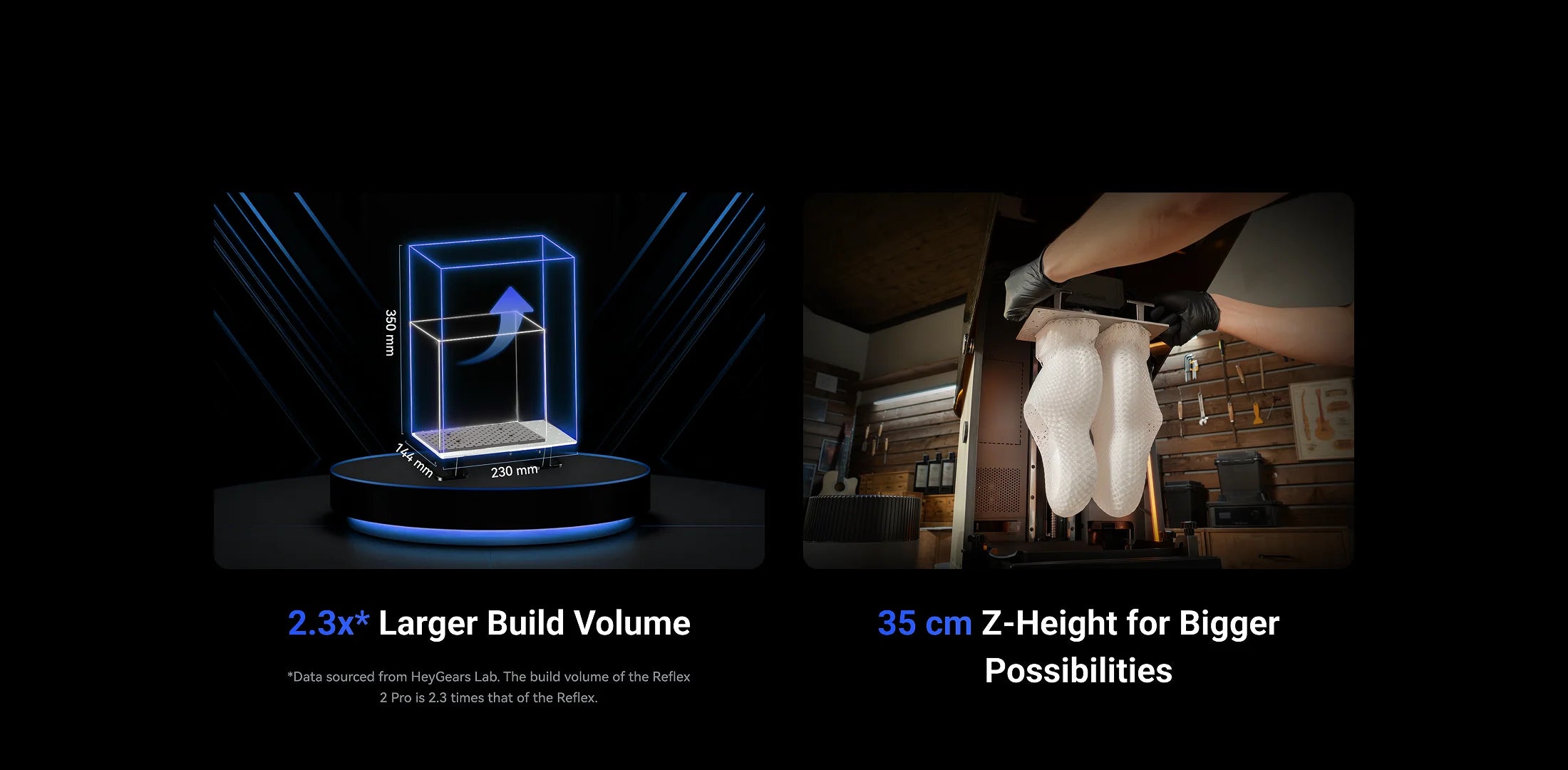

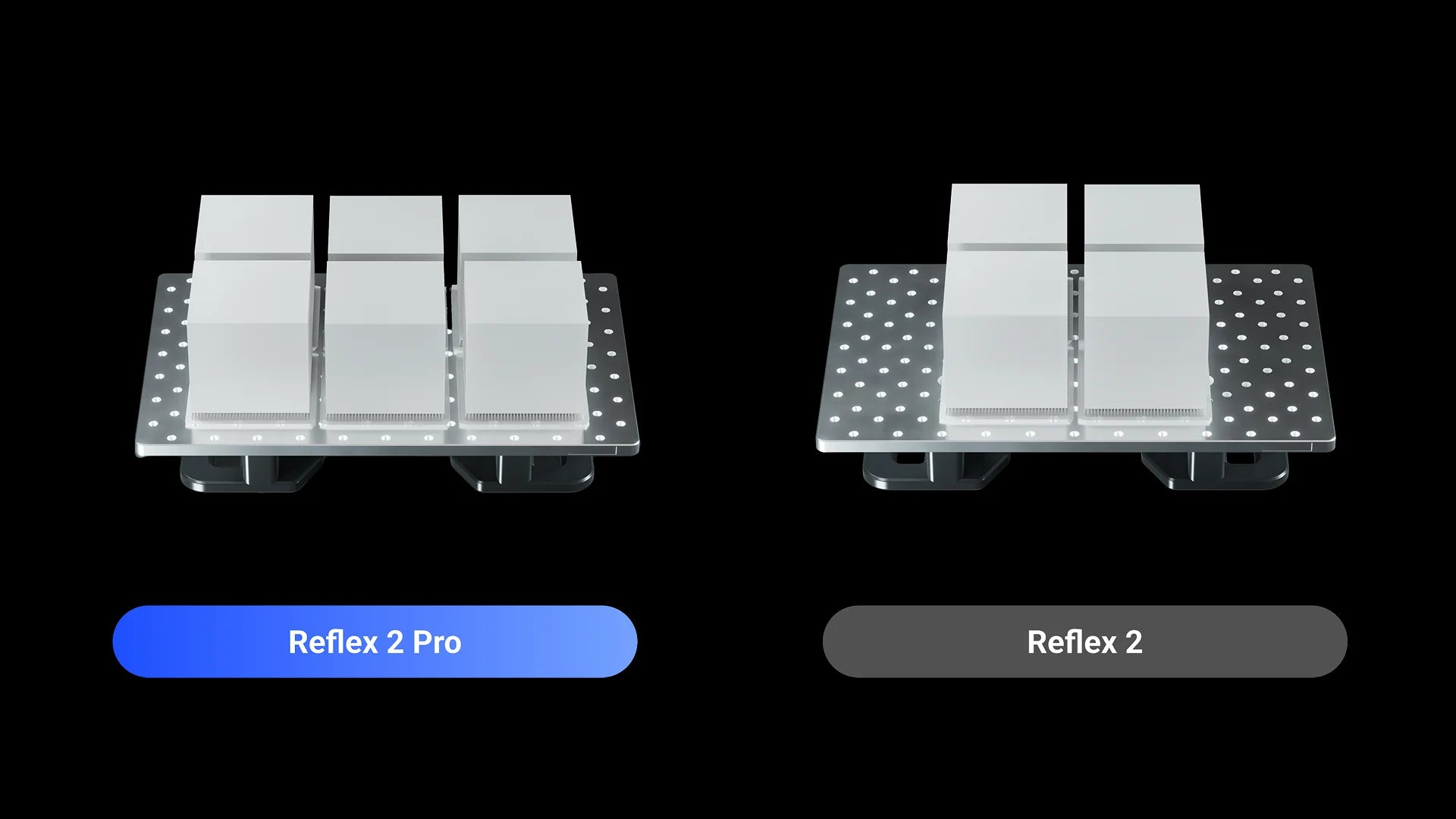

- 230×144×350 mm Build Volume, 2.3× Larger*

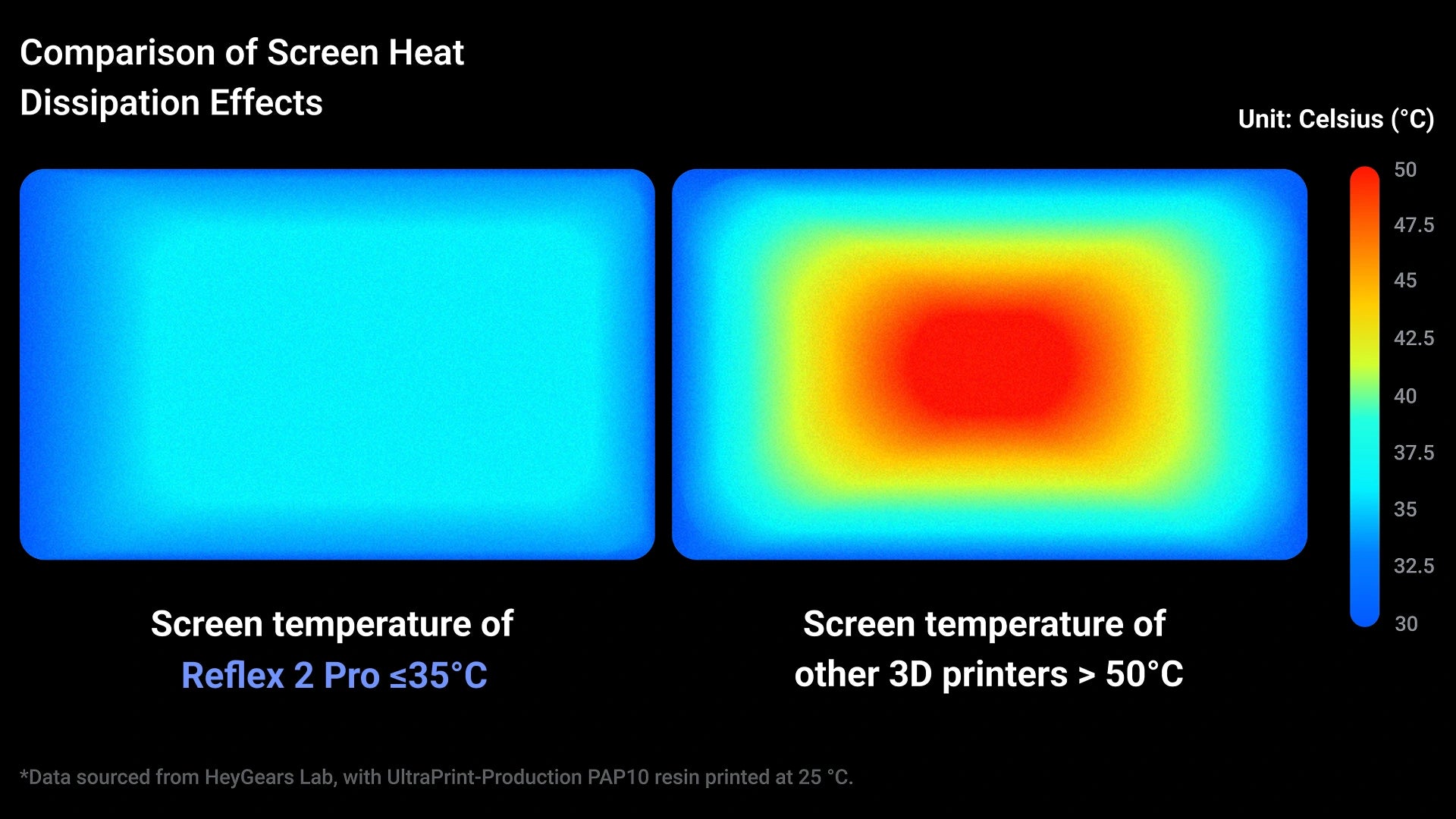

- New Amber Screen Pro, over 6000h Lifespan**

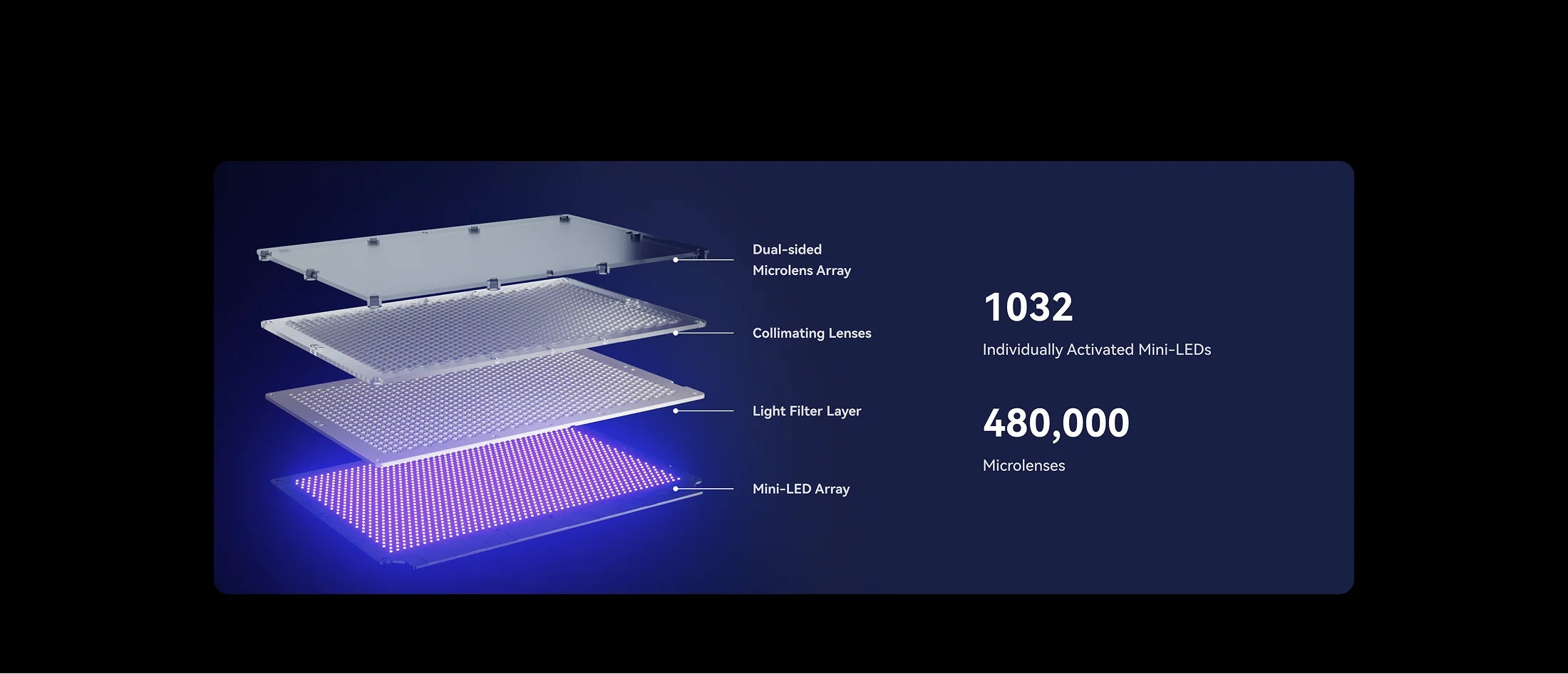

- 1032-Zone OptiZone Light Engine

- 86,000+ Zone Light Calibration

- 0.15 mm Residue Detection Sensor

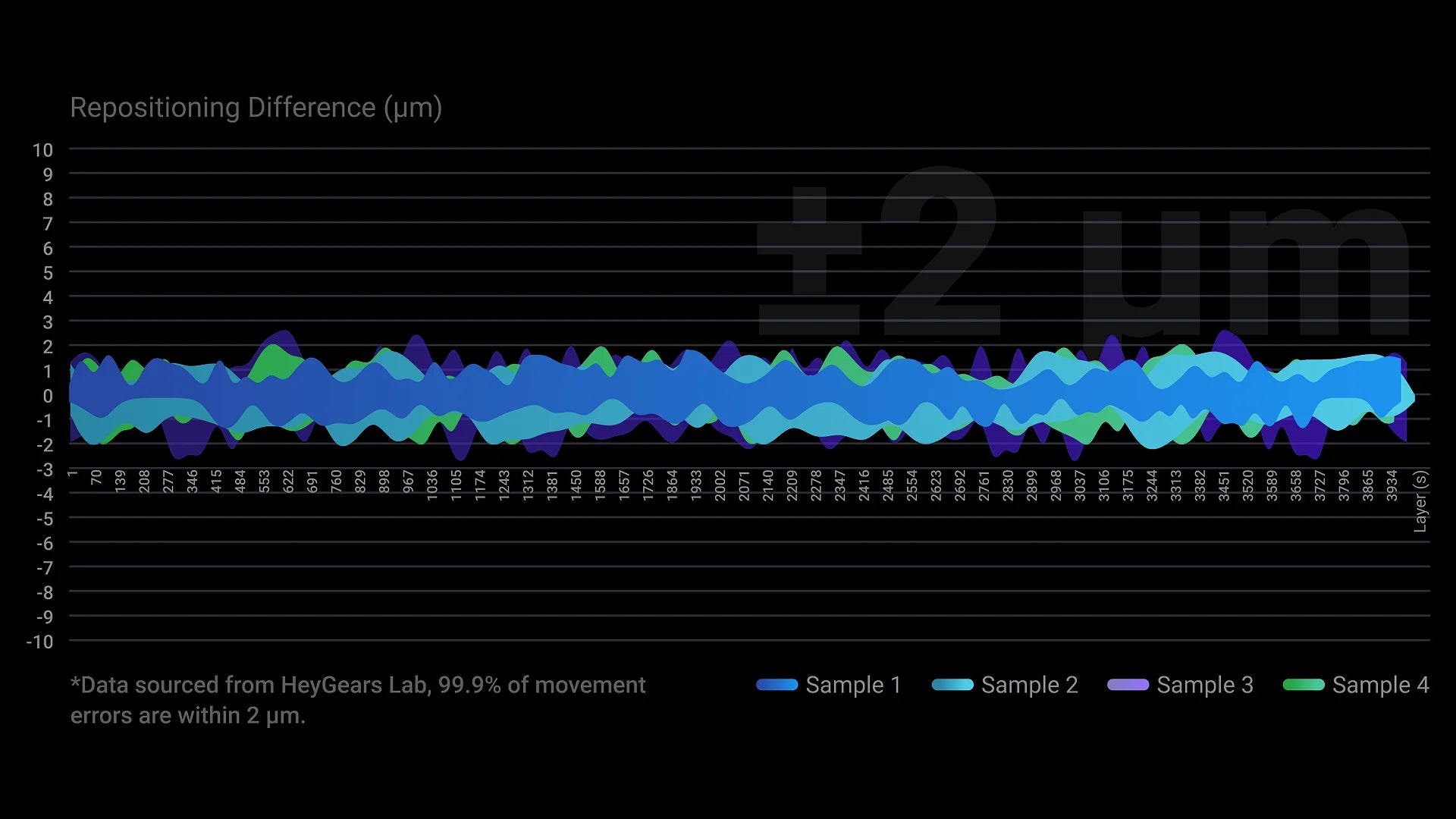

- C5 Grade Z-axis Module

- Die-Cast Unibody Base

- Intelligent Temperature Control ±1 °C

- Compatible with High-Performance Resins

*The build volume of the Reflex 2 Pro is 2.3 times that of the Reflex.

**With 6,000 hours of printing, it can be used year-round based on an average of 16 hours of daily use.

Compatible Resins

Reflex 2 Pro is currently compatible with these materials: PAC10, PAU11, PAH10 Black, PAT10, PARP10 Orange Clay, PAP10 Ash Grey, PAWR10, PAS10 Black, PAF10, PAS10 Pale Purple (using Pulsing Release Module 2), PAH270, PAT10, PAE10, PAU20.

Pairs well with

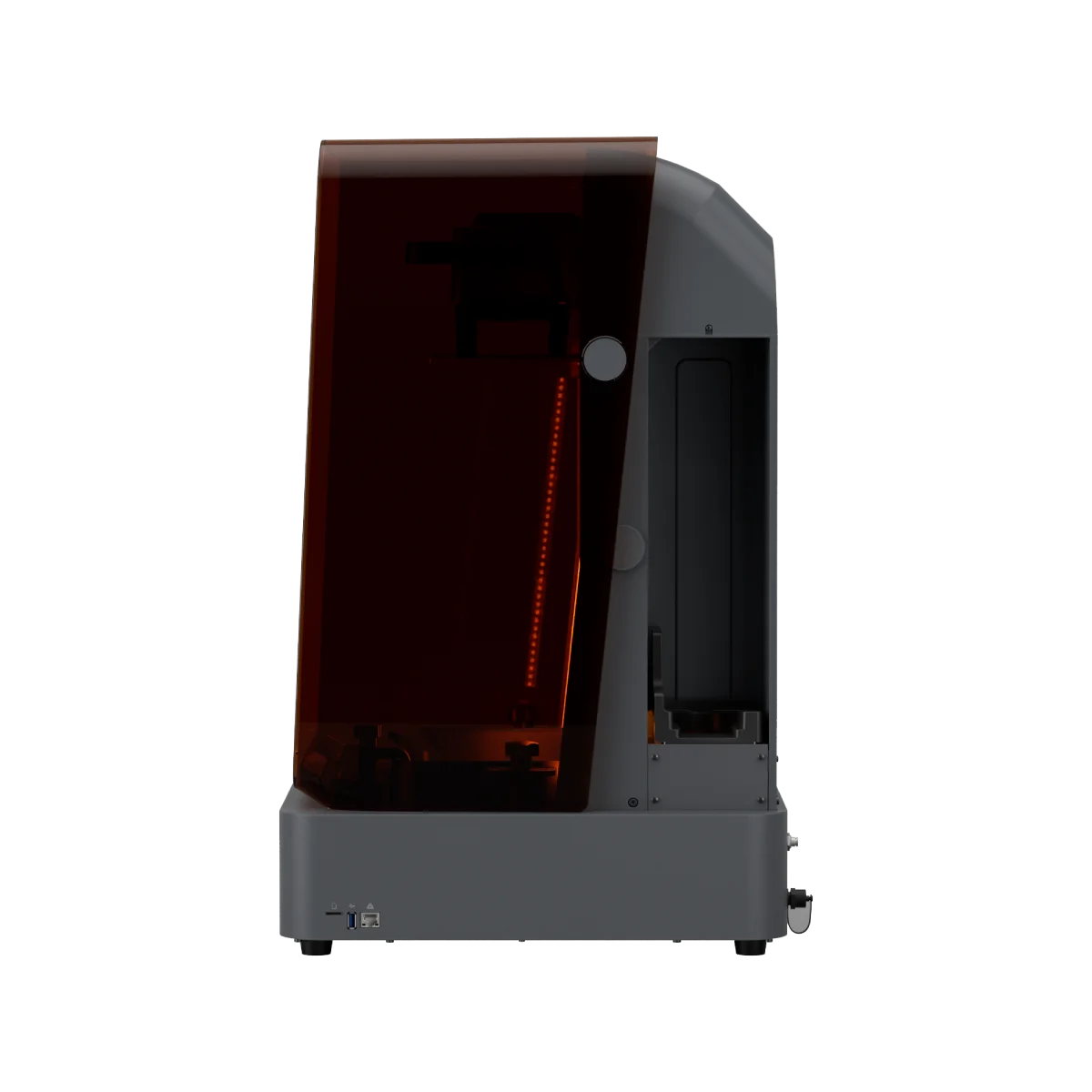

Reflex 2 Pro 3D Printer

We're committed to providing you with the best service. Please don't hesitate to reach out if you have any questions.

-

Shipping Information

Free shipping on orders over $399. Click here for more shipping details.

-

Customer Support

Need assistance? We are here to help!

WhatsApp:

+1 949-283-2998(US)

Mon-Fri, 9AM-5PM PSTEmail Support:

contact@heygears.com

Technical Support:

customersupport@heygears.com

-

Get Started

Getting Started with Your HeyGears 3D Printer

-

FAQ’s

Please read our FAQs page to find out more.

Precise Light Projection

With 1032 individually controlled light zones, the Reflex 2 Pro enables precise light projection within the printing area. This pinpoint accuracy ensures a flawless surface through optimal curing, while reducing resin residue to lower tank filtration frequency and improve production efficiency.

Optimized Multi-Part Nesting

The OptiZone Light Engine, with its 1032 individually controlled LEDs, enables the projected light area to be closely matched to the exact contours of all nested parts. This minimizes unnecessary exposure in empty regions between models, while further optimizing the surface quality and the dimensional accuracy.

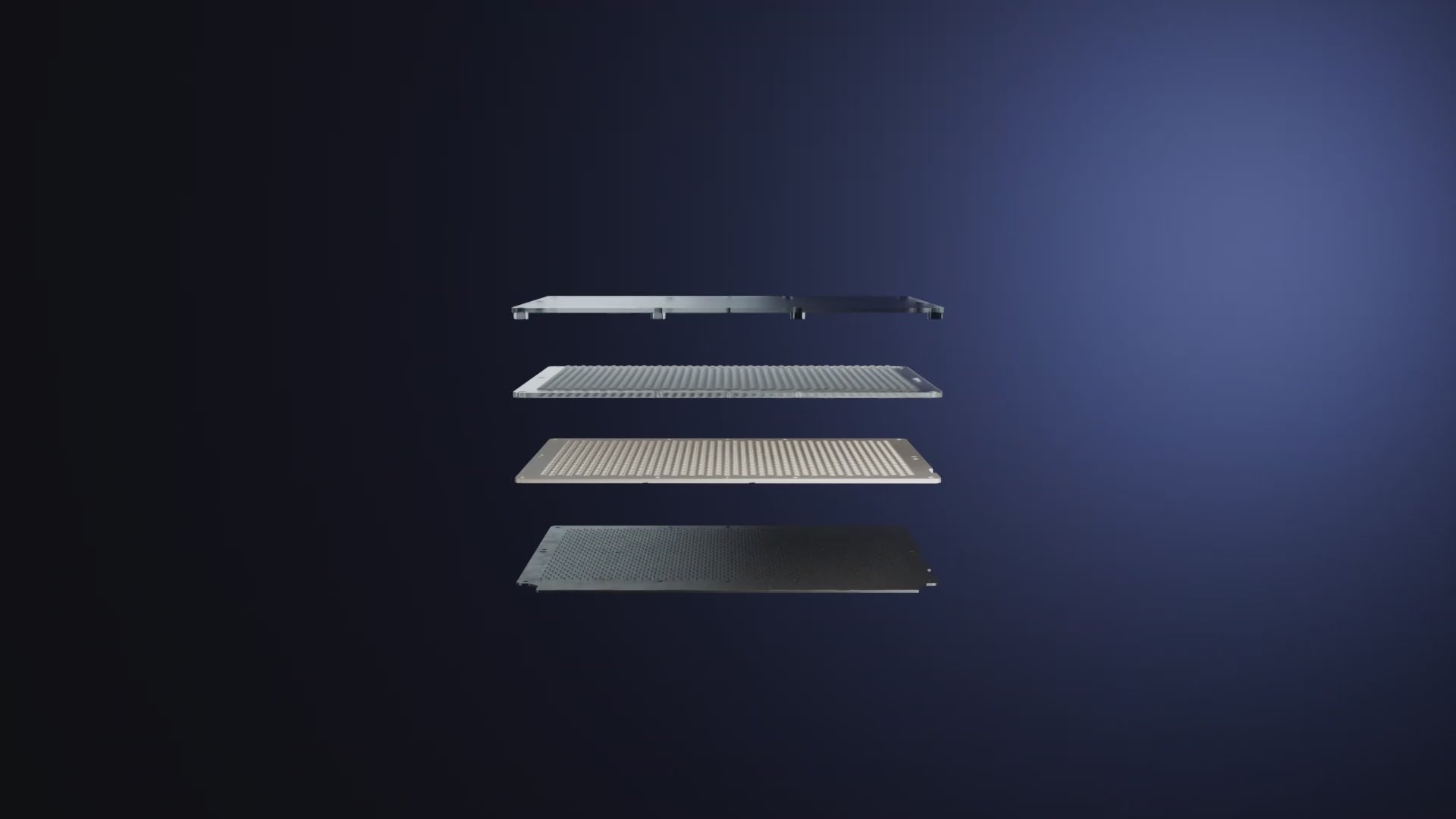

Upgraded Amber Screen Pro, Enhanced Batch-Production Reliability

2x Energy Transmission Rate*

With its high 10% energy transmission rate, double that of conventional LCD printers, the Amber Screen Pro supports a light intensity of up to 35 W/m² for curing, which effectively reduces the exposure time for each layer and opens more possibilities of higher performance resins.

*Data sourced from HeyGears Lab, compared to conventional LCD screens with a 5% transmission rate.

Upgraded UV Resistance for 6,000+ Hours Usage

Featuring a large-molecule liquid crystal layer, the Amber Screen Pro demonstrates exceptional resistance to UV degradation, maintaining good performance even under prolonged high-intensity exposure, ensuring over 6,000 hours of printing*. This durability is backed by a 1-year warranty**.

*Data sourced from HeyGears Lab. The contrast and light transmission of the Amber Screen Pro remain within a 10% deviation after 6000 hours of printing. **With 6,000 hours of printing, it can be used year-round based on an average of 16 hours of daily use.

100x More Pressure Resistant, No Fear of Printing with High-Viscosity Resins

Engineered with structurally reinforced support pillars in the liquid crystal layer, the Amber Screen Pro exhibits excellent pressure resistance—over 10,000 cycles at a 40 kg load causes no damage, effortlessly handling the continuous stress of high-viscosity resins.

*Data sourced from HeyGears Lab. Testing was conducted using a 5x5 mm surface pressure test model that pressed the screen under a 40 kg load, simulating the mechanical stress the screen experiences during the peeling process in printing.

AI-Powered 86,000+ Zone Light Calibration

The upgraded visual calibration algorithm, MASK, uses 86,020 calibration zones to compensate for light intensity variations in each screen zone. This method achieves ≥94% light uniformity and print accuracy of ≤0.05 mm*.

*Data from HeyGears Lab: Indicating the dimensional deviation for a printed test model measuring equal to or less than 20 mm in the XY direction. Test results are within the 95% confidence interval.

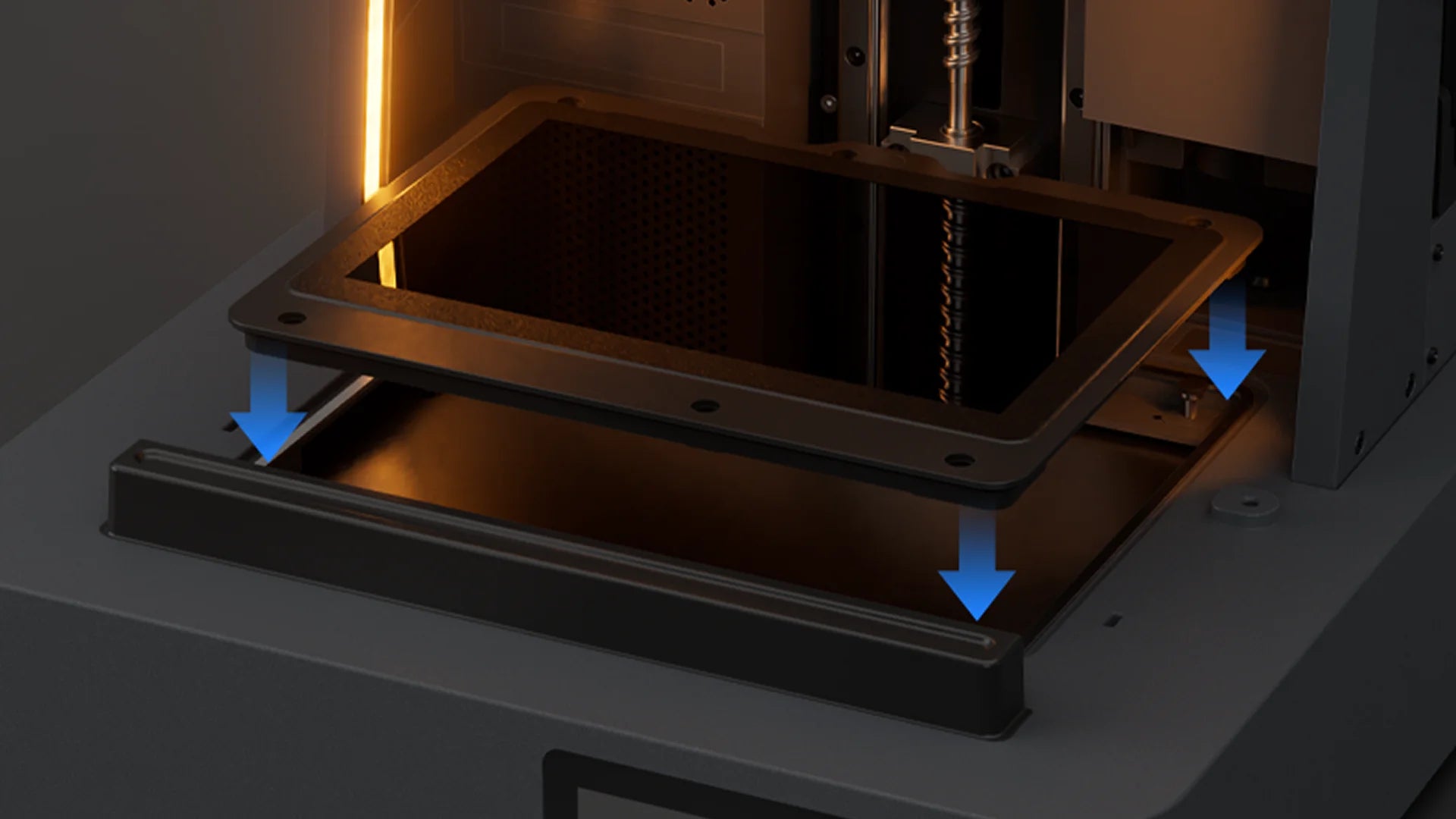

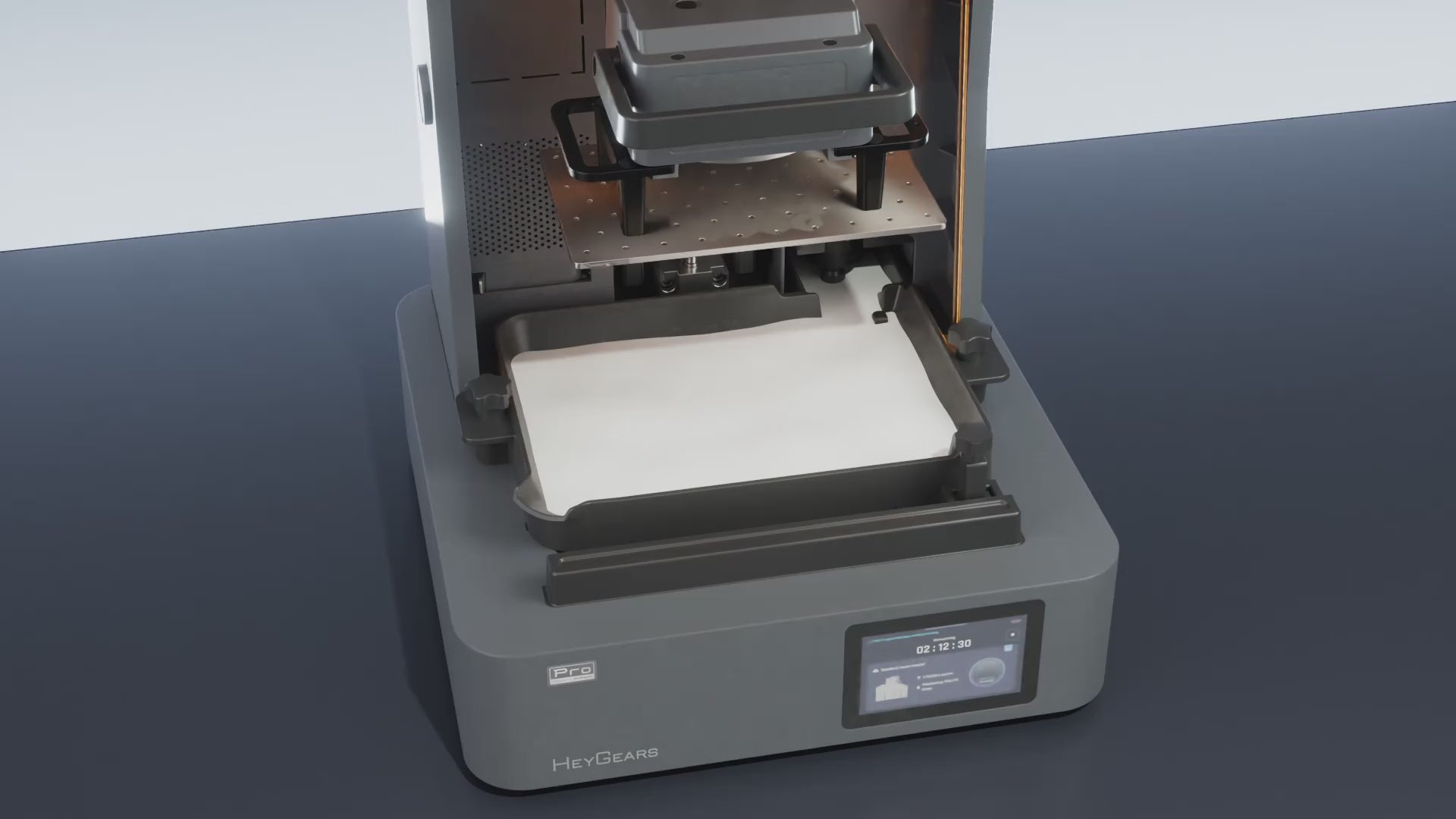

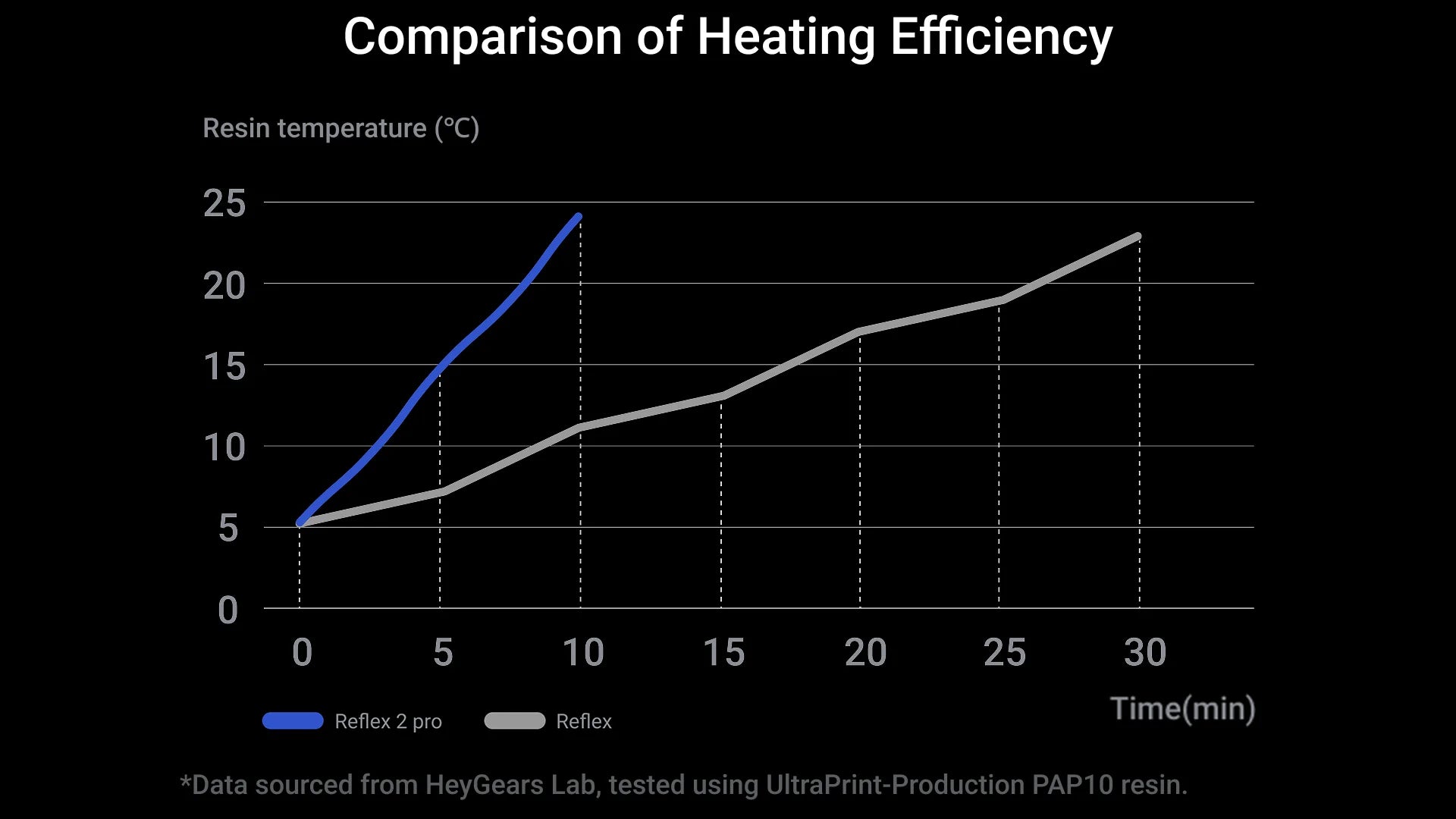

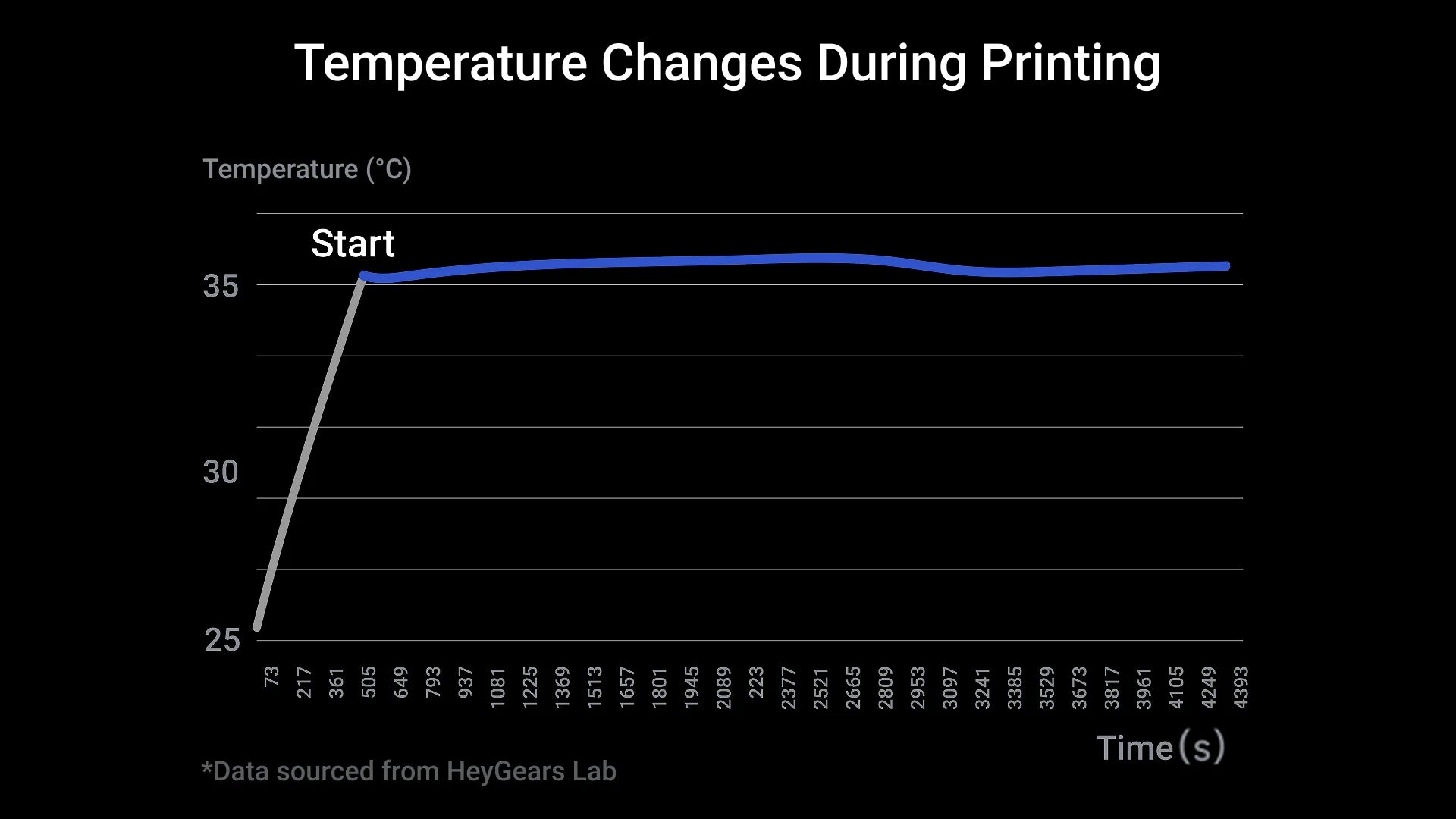

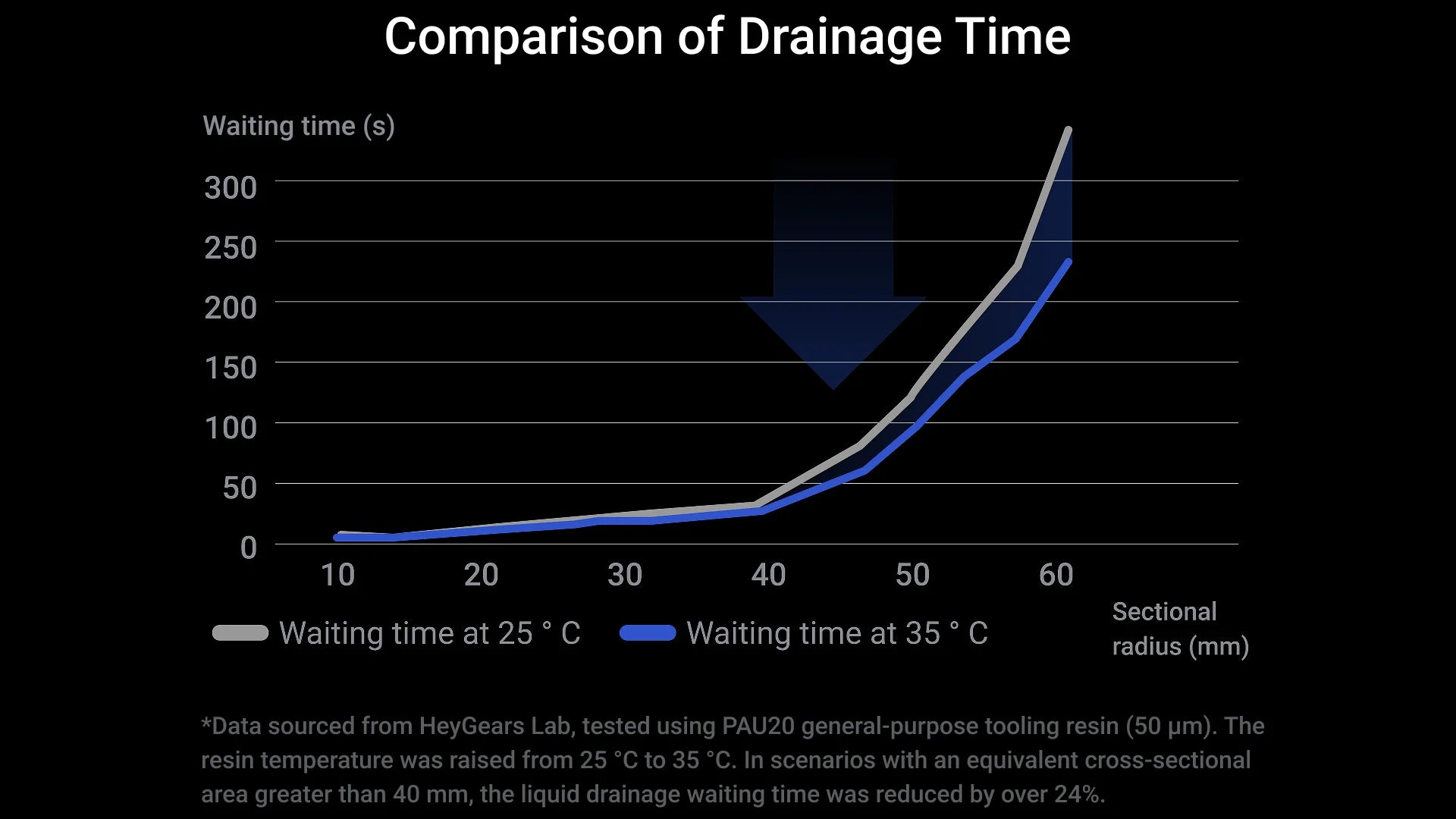

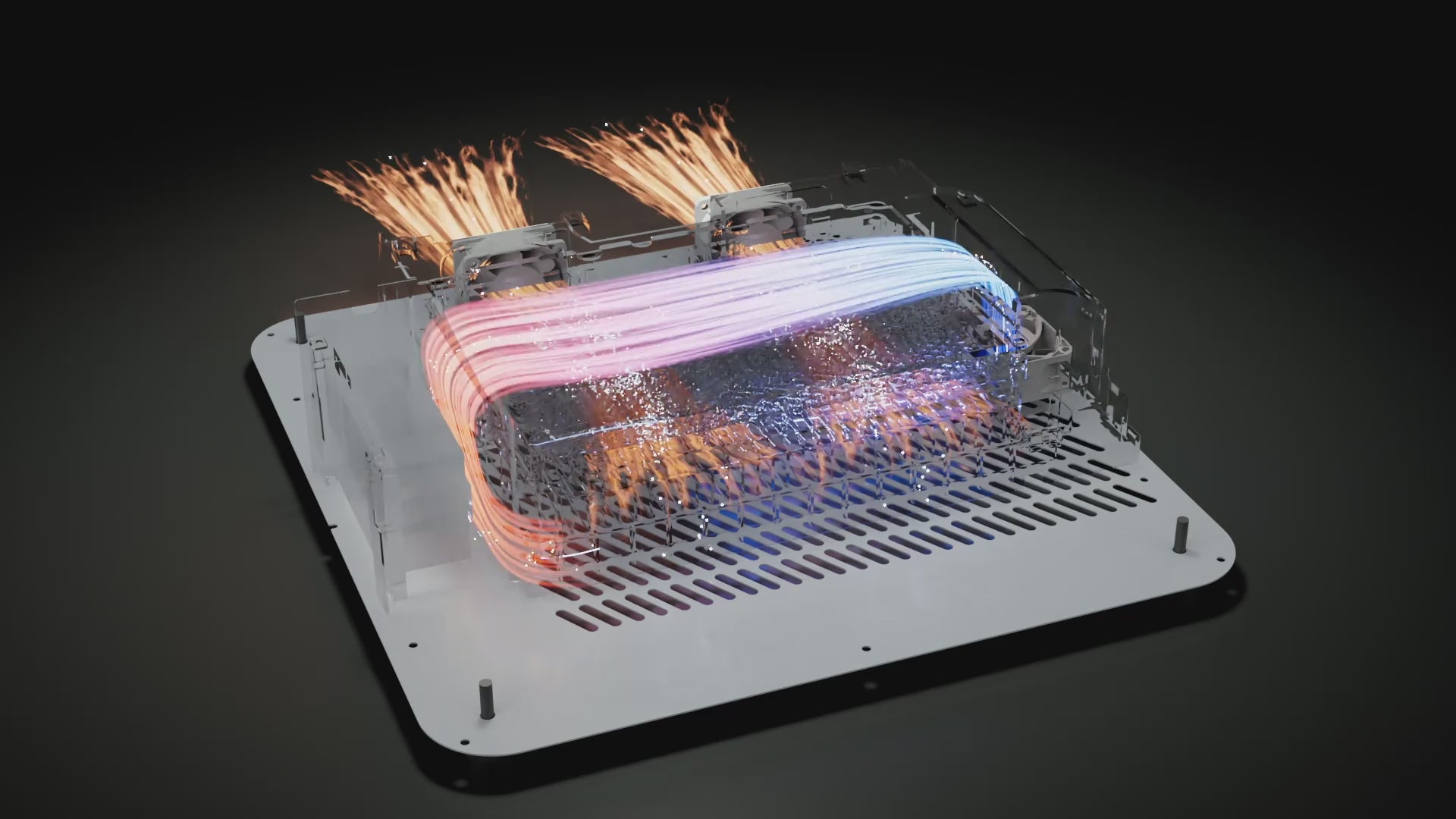

Intelligent Temperature Control: Enhancing 3D Printing Success Rates

The Reflex 2 Pro features a smart scraper-assisted temperature control system which heats the resin more efficiently, keeping it at optimal printing temperature during the whole printing process and prevents resin sedimentation and residue at the same time.

Intelligent Features, Boosting Print Success

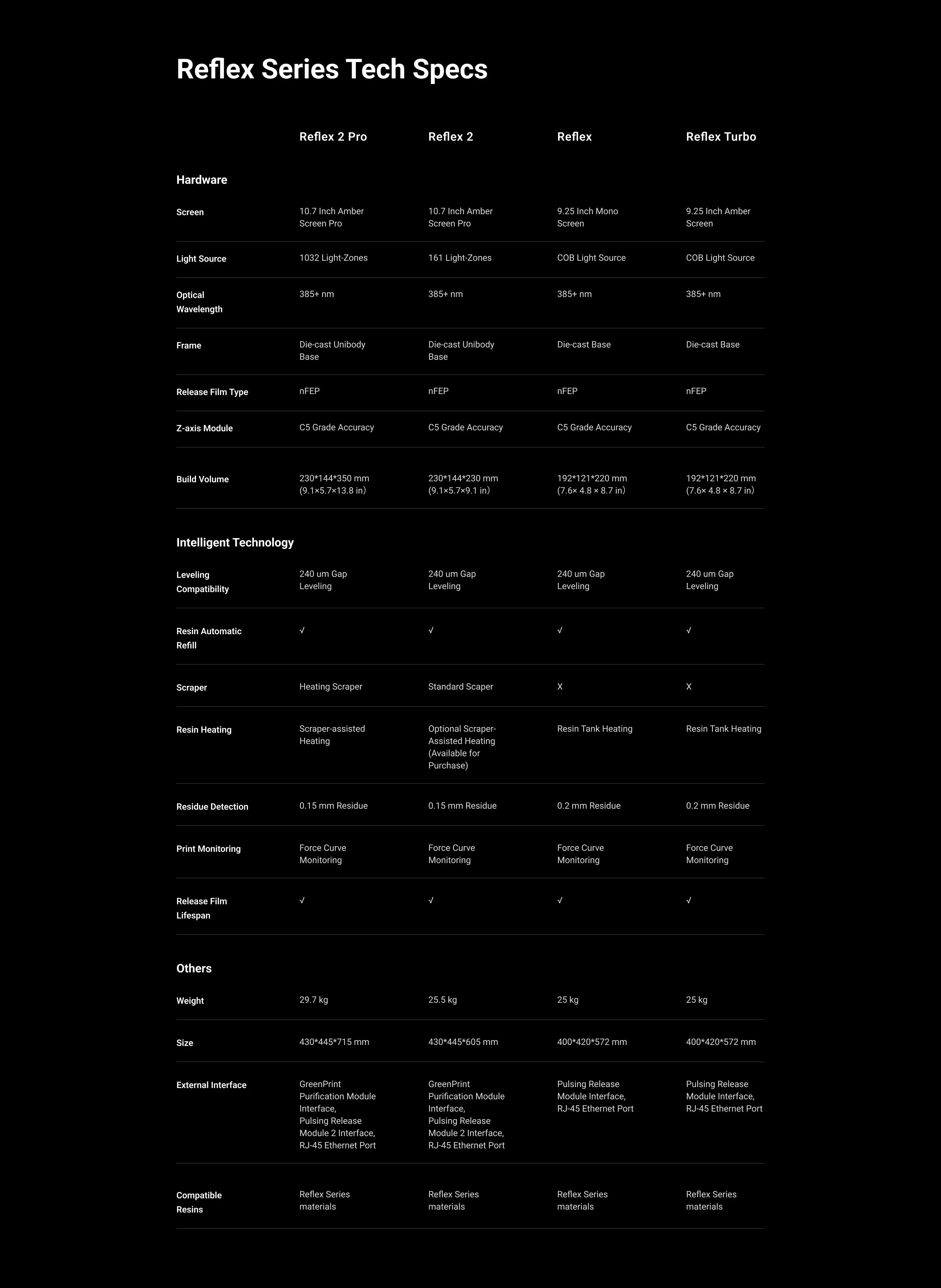

Specifications

Product Name:

UltraCraft Rapid Production System

Product Model:

UltraCraft Reflex 2 Pro

Marketing Name:

Reflex 2 Pro

3D Printing Technology:

LCD (MSLA)

Screen:

10.7 Inch Amber Screen Pro

Optical Wavelength:

385+ nm

Z-axis Module:

C5 Grade Accuracy

Build Volume:

230×144 x 350 mm (9.1×5.7×13.8 in)

Resin Heating:

Scraper-assisted Heating

Leveling Compatibility

240 um Gap Leveling

XY Native Pixel:

40μm

Accuracy:

±20 μm

Layer Thickness:

20-250 μm

Residue Detection:

0.15 mm Residue

External Interface:

• GreenPrint Purification Module Interface

•Pulsing Release Module 2 Interface

• RJ-45 Ethernet Port

Weight:

29.7 kg

Rated Power:

750 W

Voltage:

100-240V~50/60 Hz

Size:

430*445*715 mm

Connectivity:

USB, WIFI, LAN

Language:

English, Simplified Chinese

Compatible Resin

Compatible with all Reflex Series materials

Included in the Box

Printer

Heating Scraper

Resin-Refill Lid

Power Cord

Part Removal Tool

Resin Tank

Part Removal Tool

Build Platform

T-Type Wrench

Quick Start

After-sales Service Guide