Product Highlights

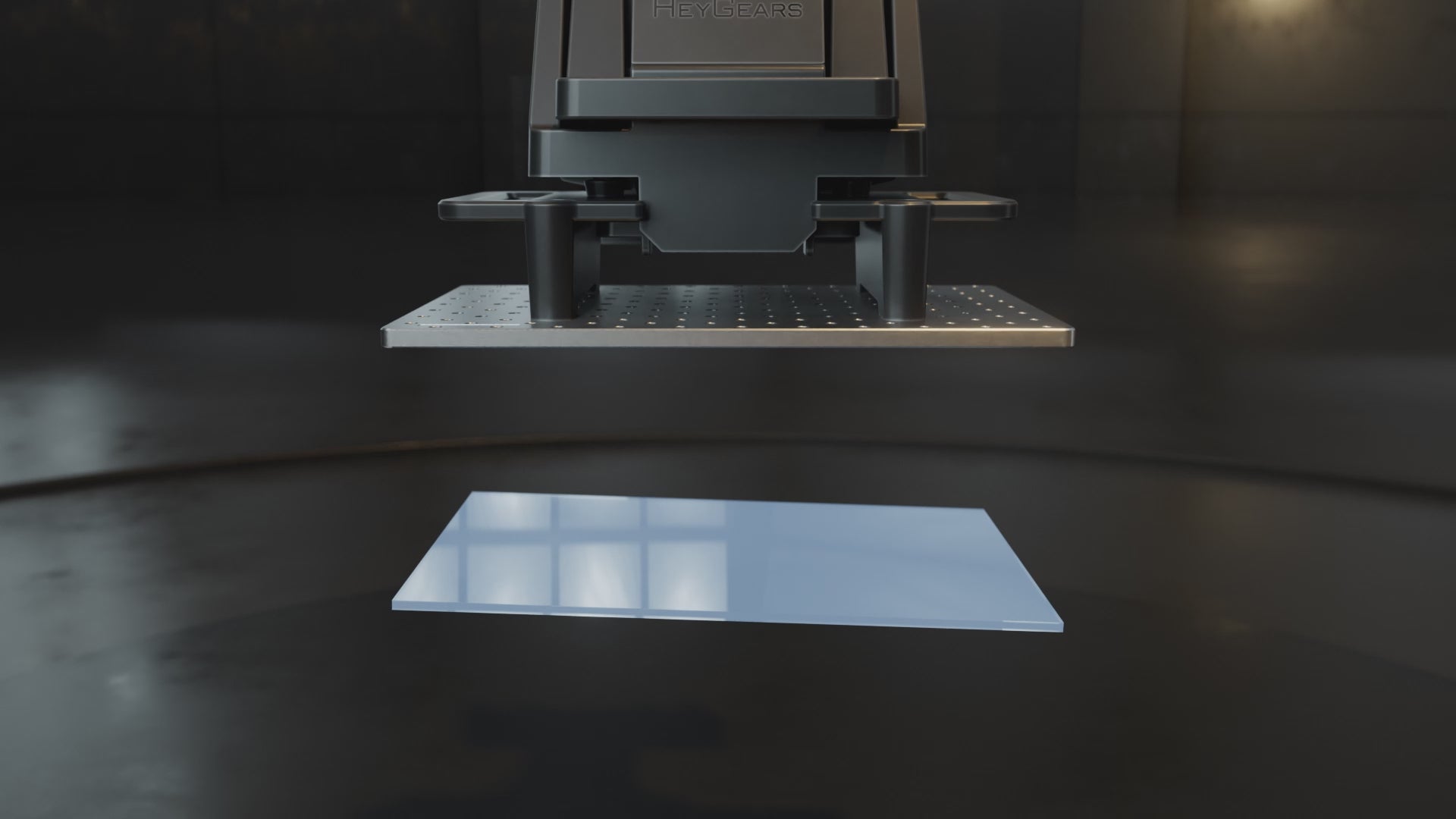

- Fully Interconnected Print Strategies

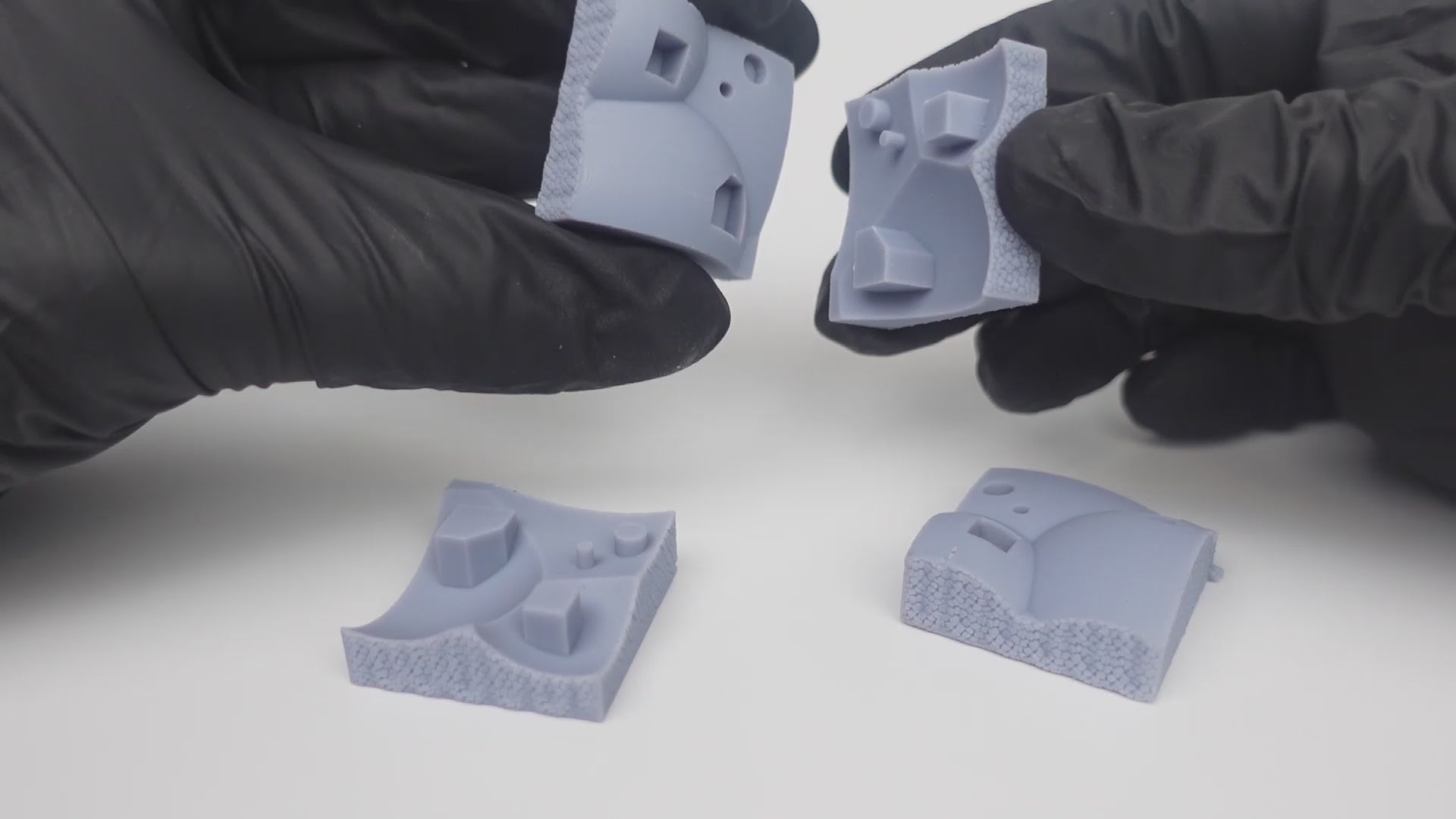

- Smart AI Peeling Force Management

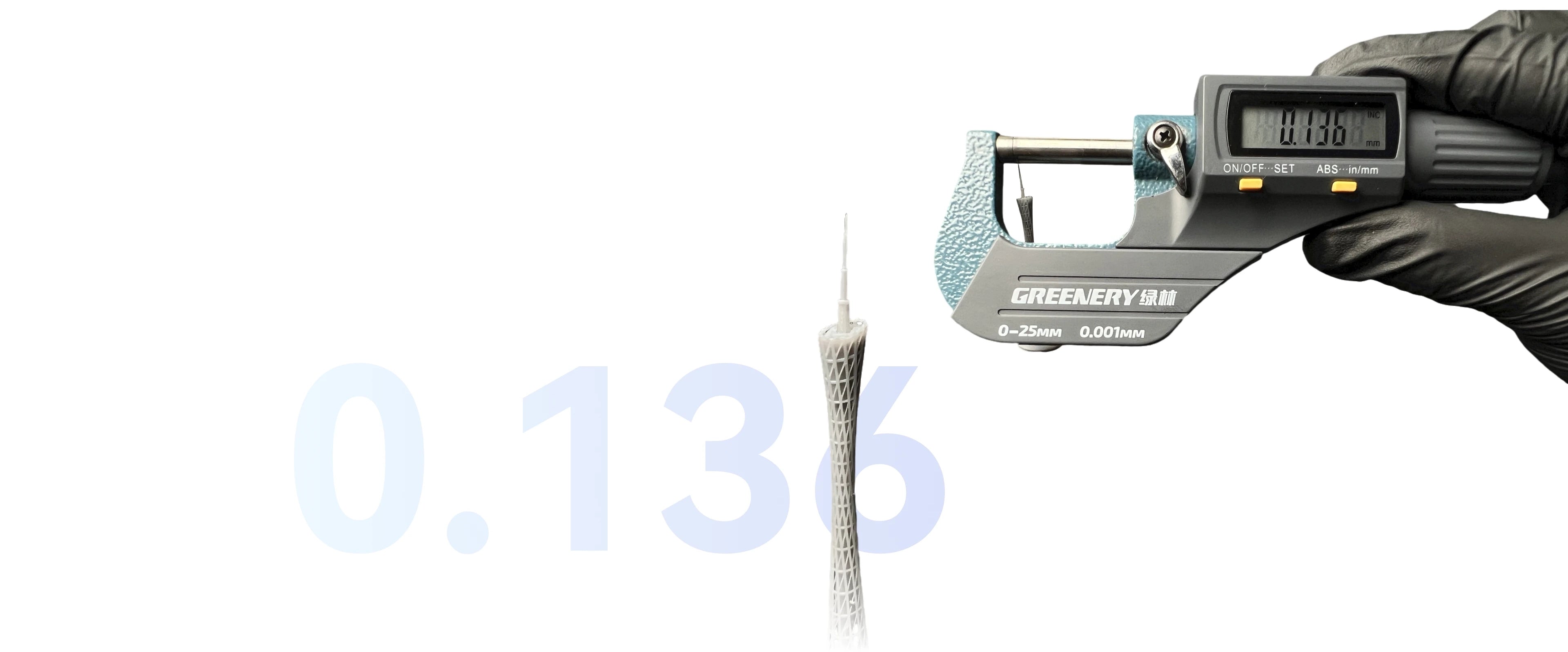

- 33 μm Precision

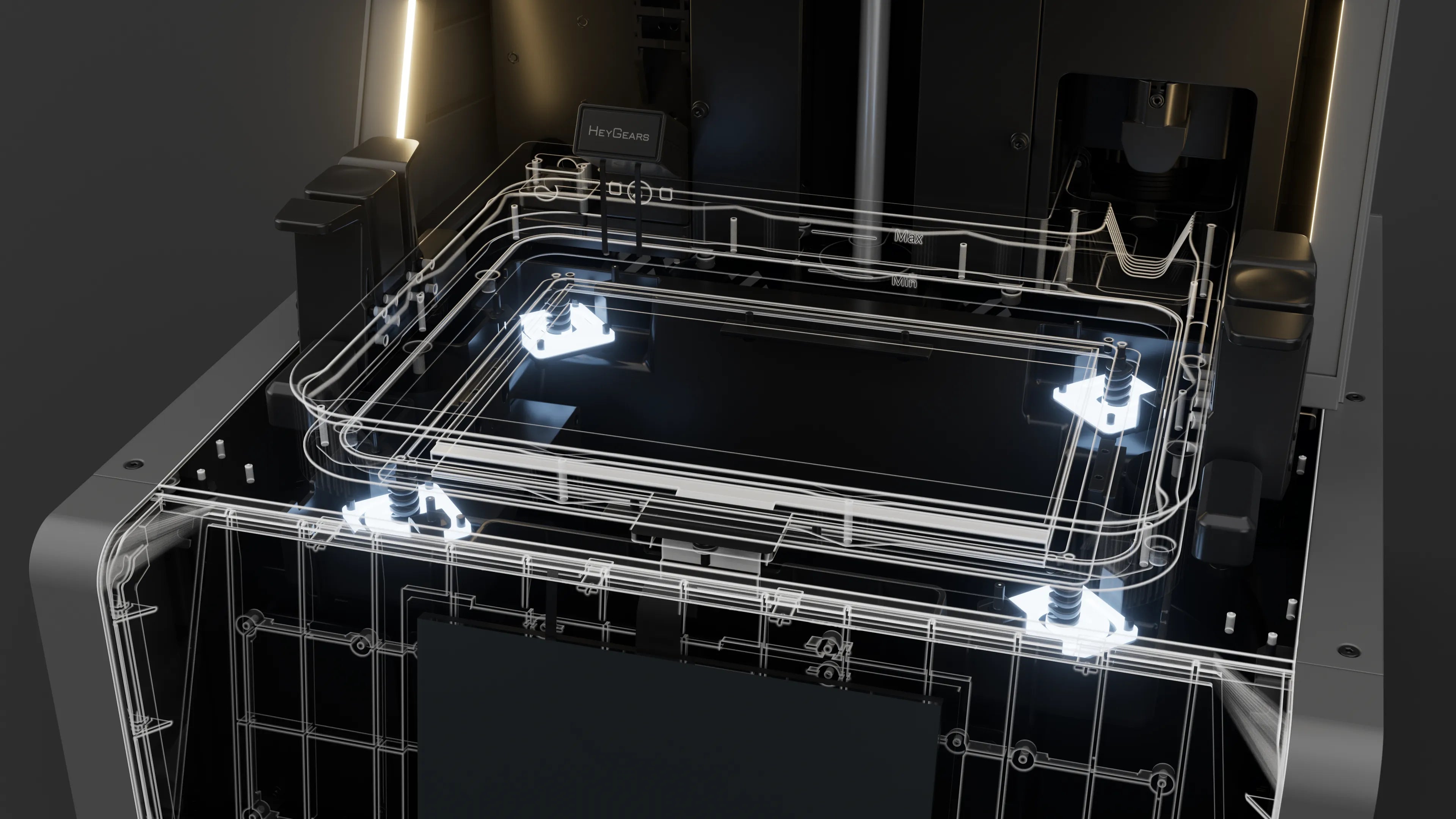

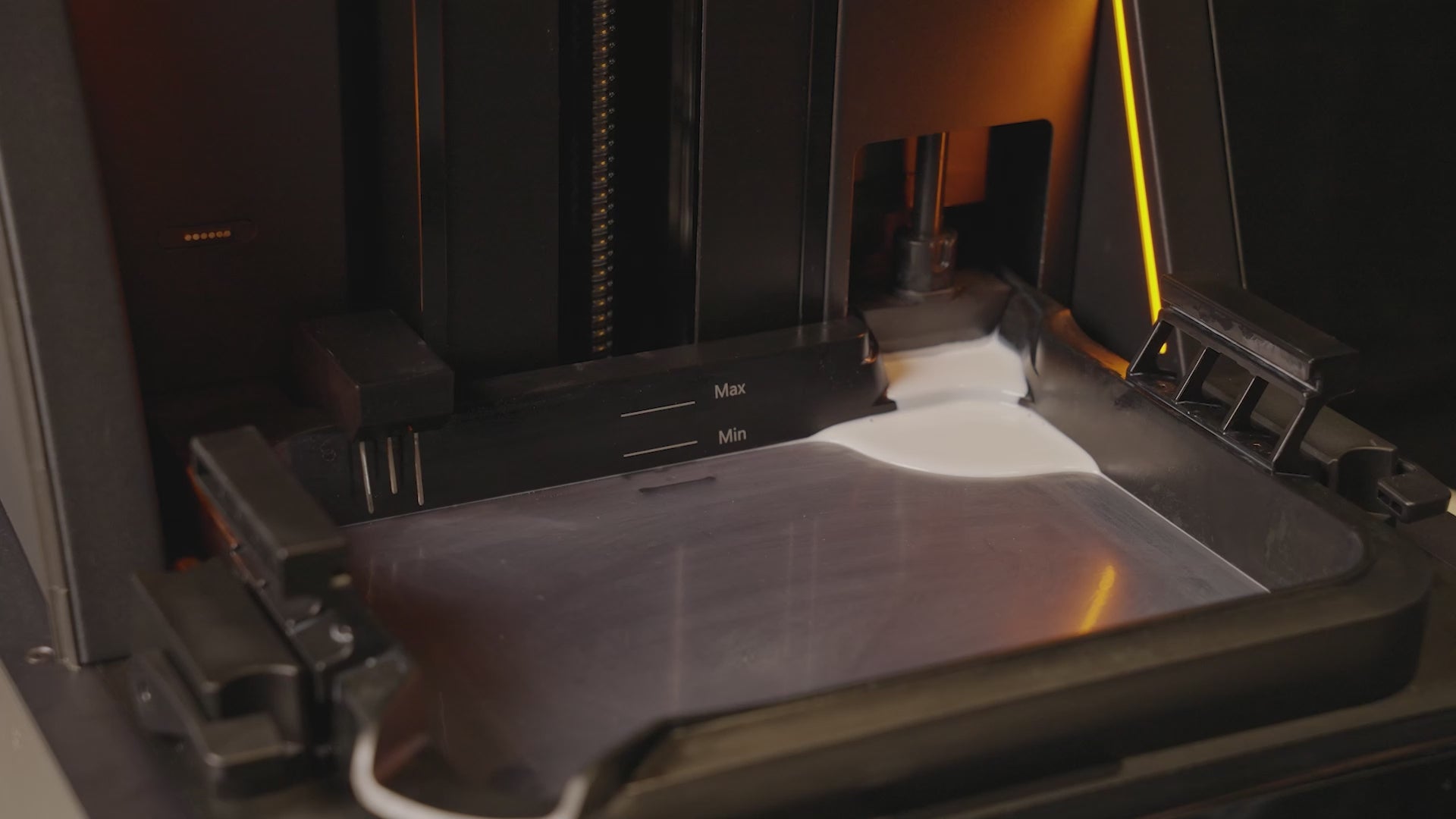

- Auto Resin Level Detection

- Auto Resin Refill

- Auto Heated Tray

- Wash without Resin Contact

- Optimized Dual Curing for Greater Material Performance

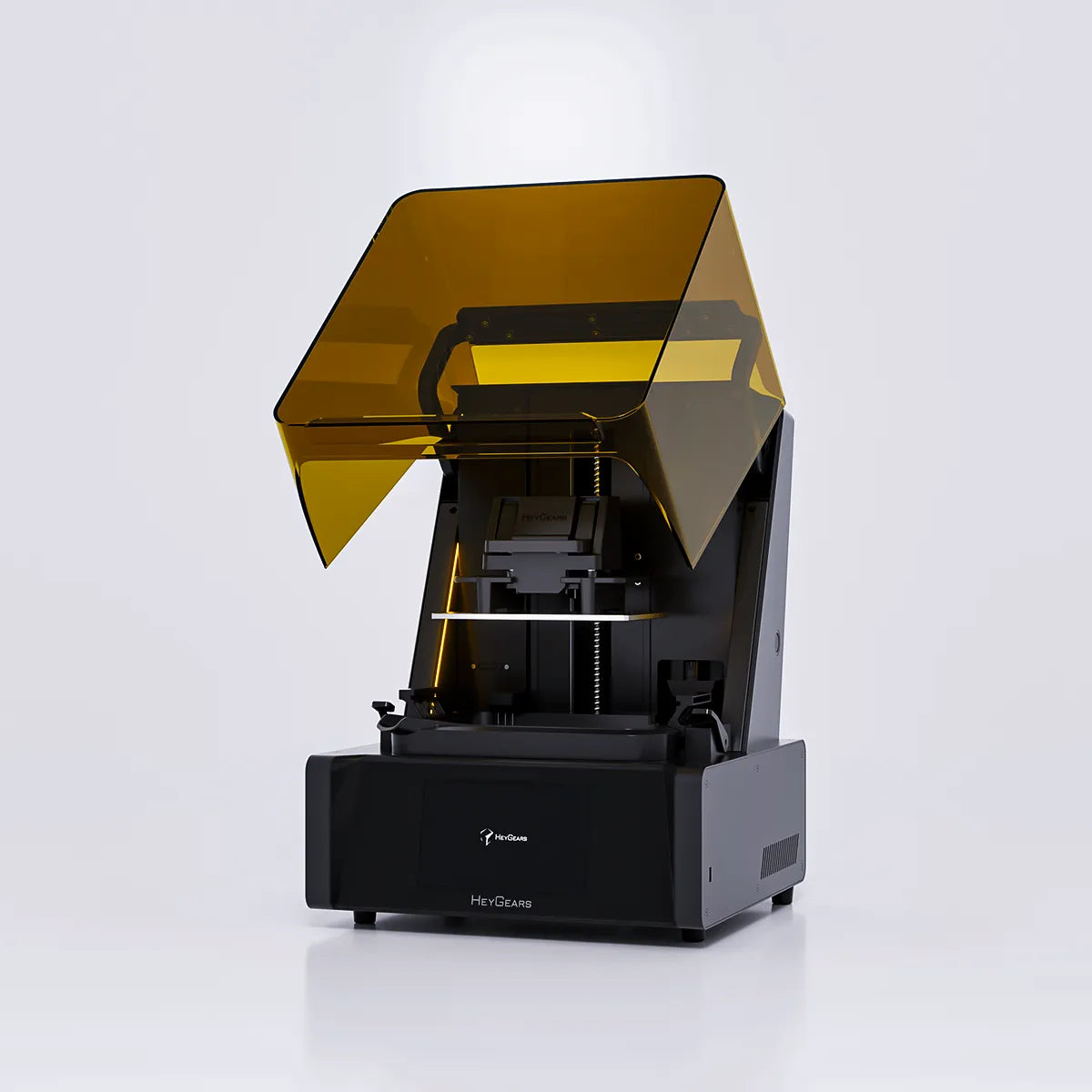

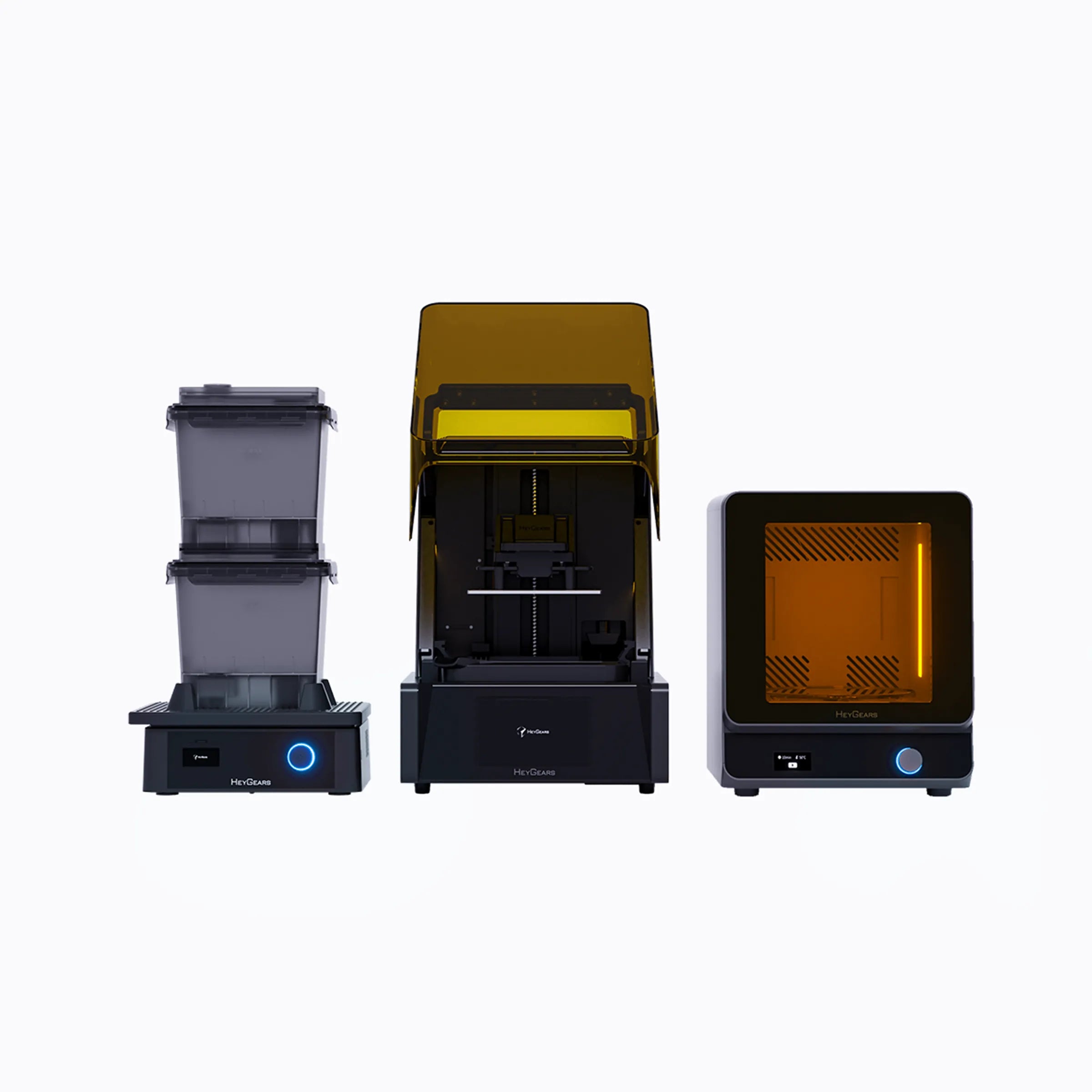

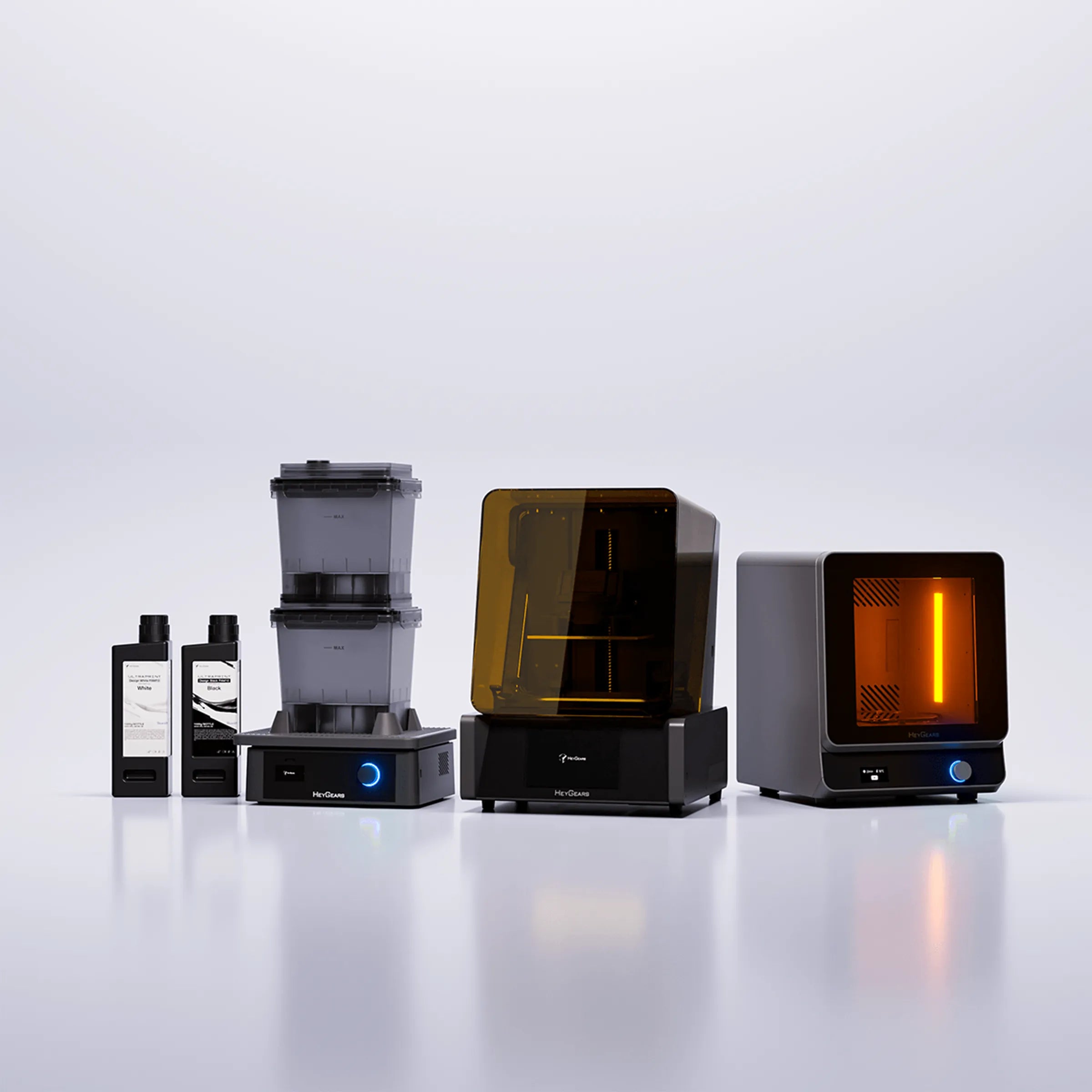

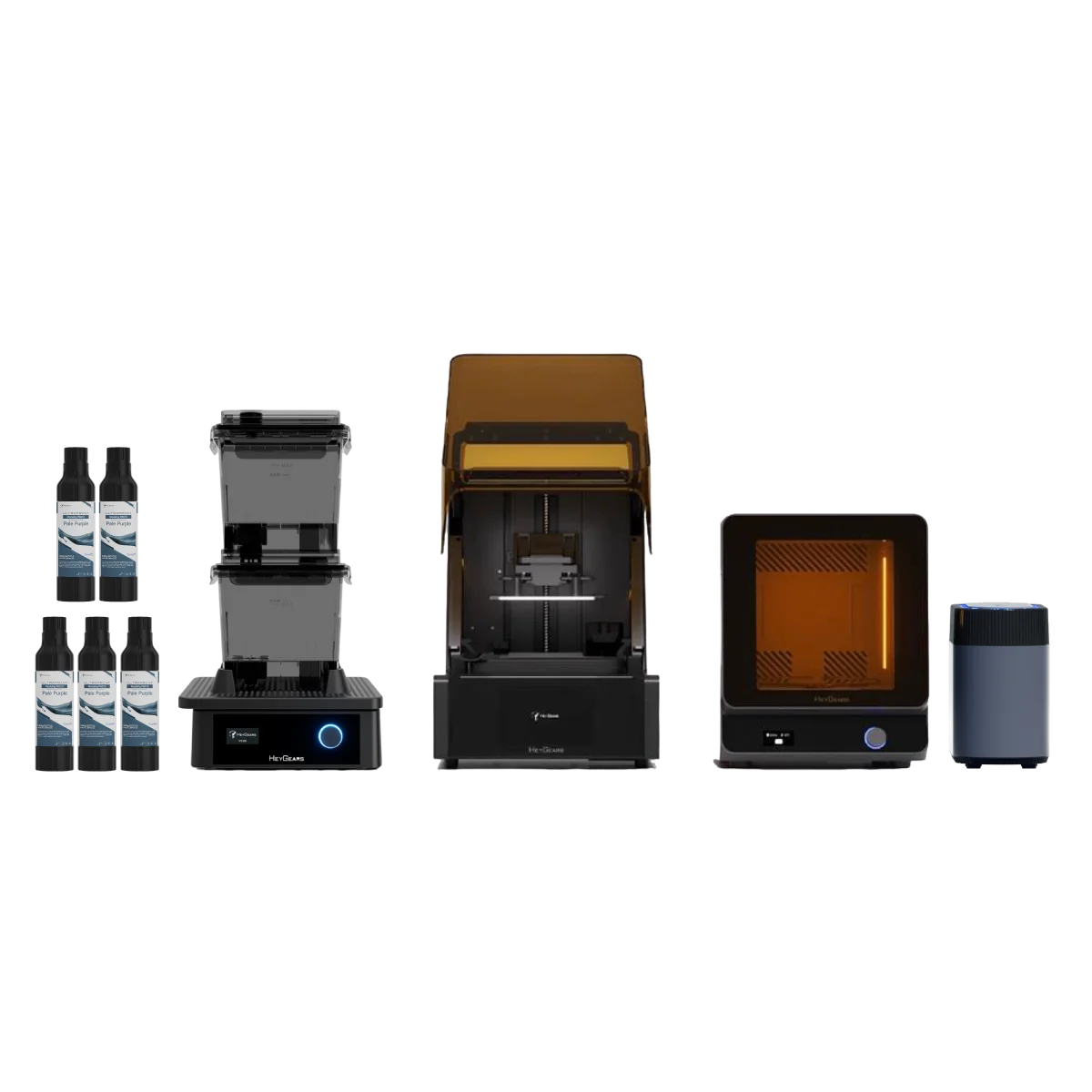

- UltraCraft Reflex 3D Printer x1

- UltraCraft Wash x1

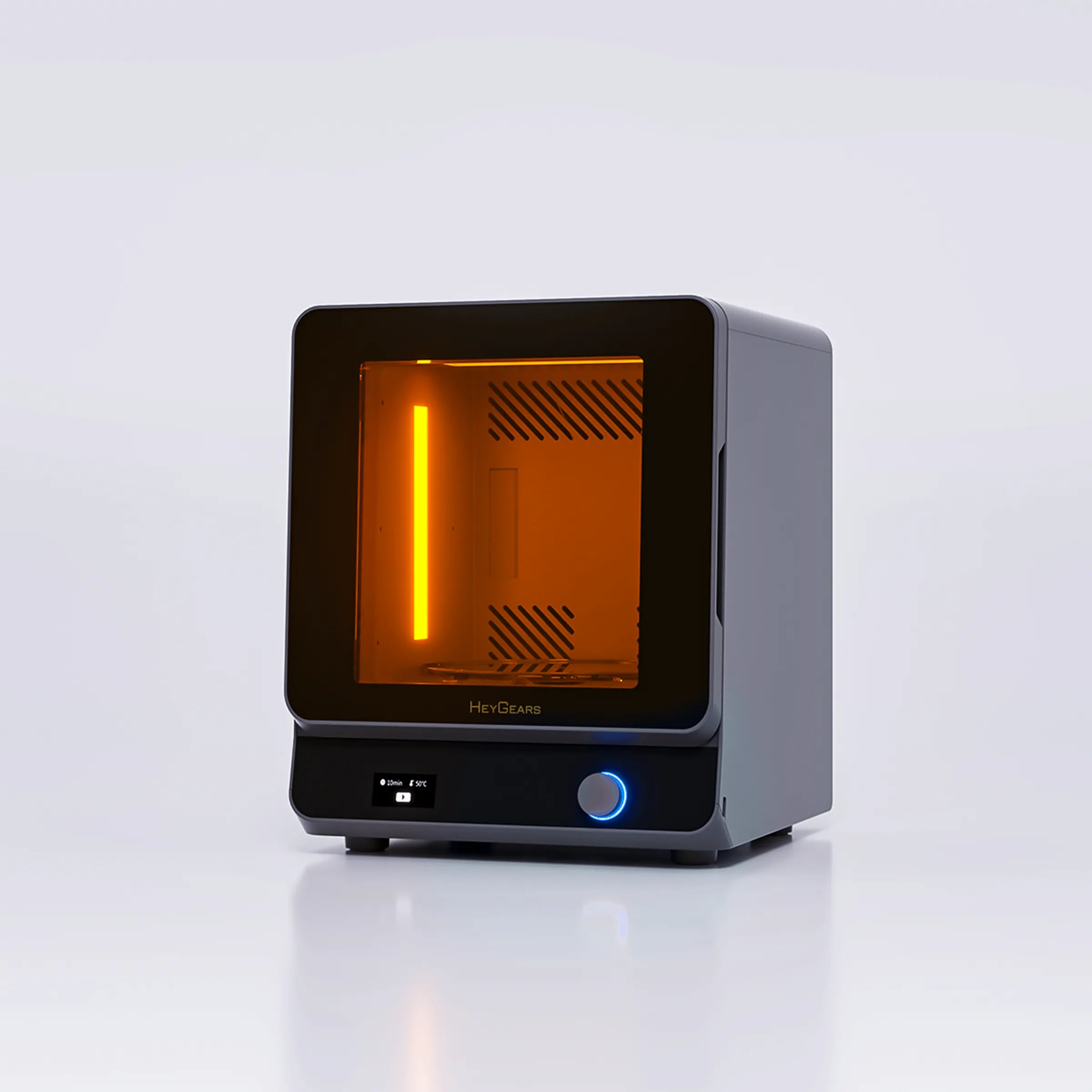

- UltraCraft Cure x1

Extra $50 Off Code: 50XMASNEW

New to HeyGears? Get $50 Off 3D Printers – Use Code: 50XMASNEW

(New users only. Valid for 3D printers.)

Popular upgrades

Pairs well with

Reflex Combo

We're committed to providing you with the best service. Please don't hesitate to reach out if you have any questions.

-

Shipping Information

Free shipping on orders over $399. Click here for more shipping details.

-

Customer Support

Need assistance? We are here to help!

WhatsApp:

+1 949-283-2998(US)

Mon-Fri, 9AM-5PM PSTEmail Support:

contact@heygears.com

Technical Support:

customersupport@heygears.com

-

Get Started

Getting Started with Your HeyGears 3D Printer

-

FAQ’s

Please read our FAQs page to find out more.

Hear It From Our Users

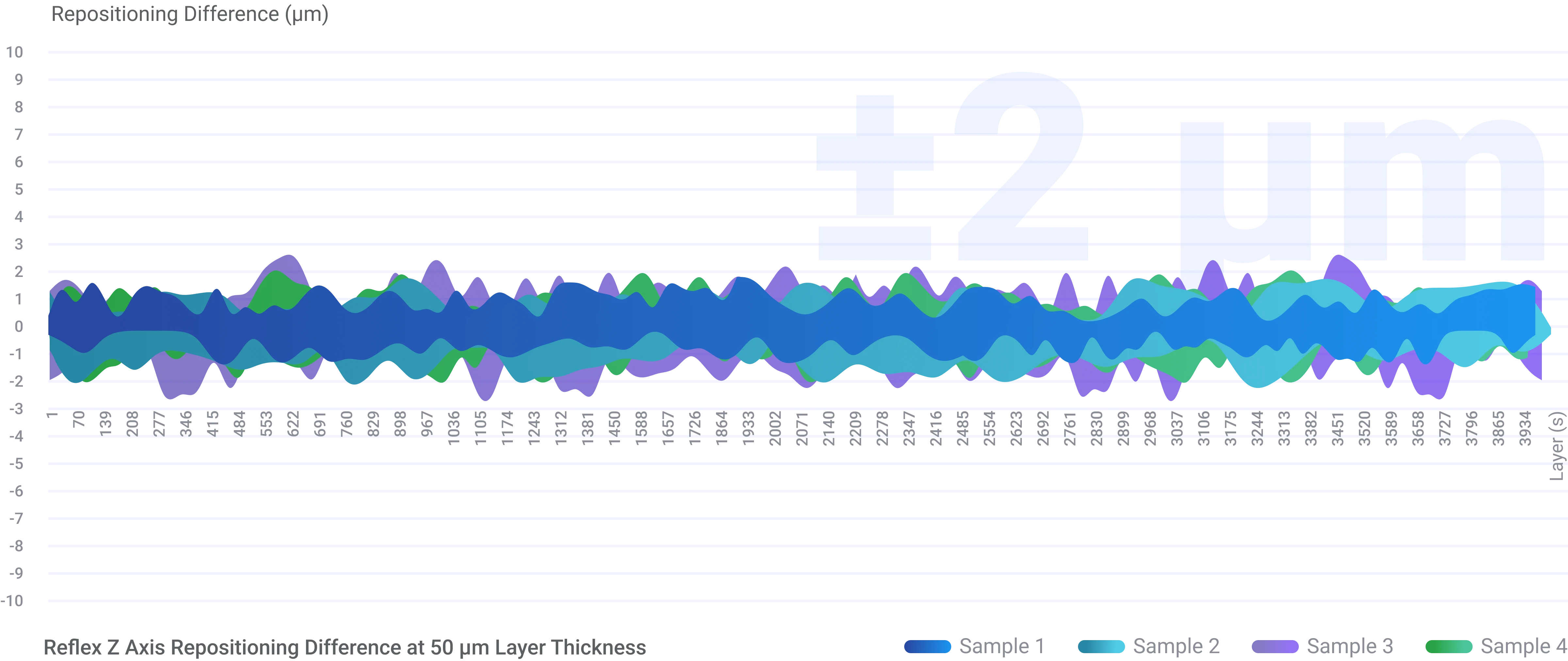

C5 Z-grade Module

Eliminate layer gaps with a Z-axis repositioning accuracy of ±2 µm.

Zero Tolerance Assembly Results*

*Data sourced from HeyGears Lab, tested with PAS10 standard modeling resin.

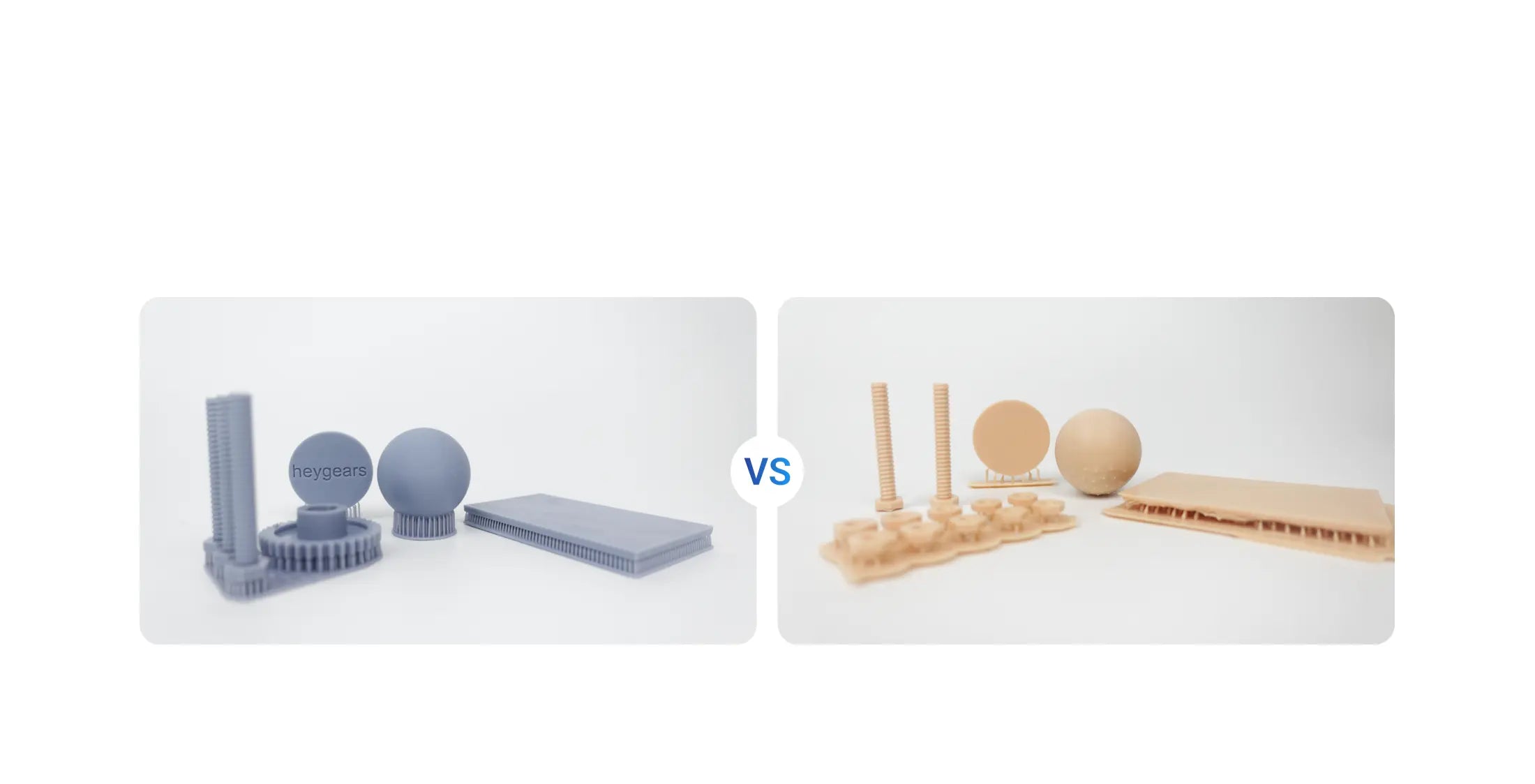

90.6% Detail Restoration

Comparing the 3D printed models and their digital designs, 90.6% of the 3D printed models have a surface tolerance of ≤0.05 mm.

*Data sourced from HeyGears Laboratory

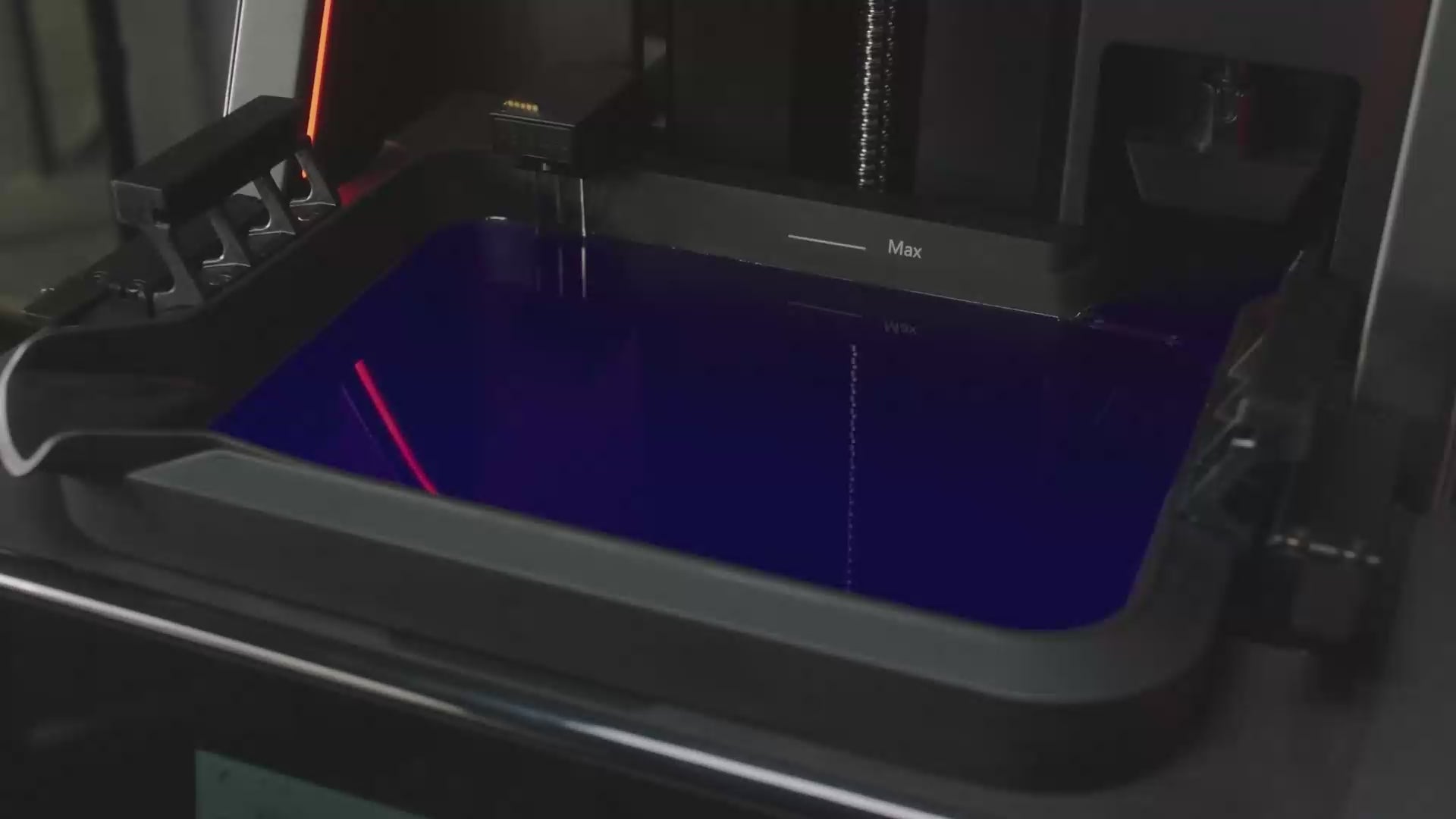

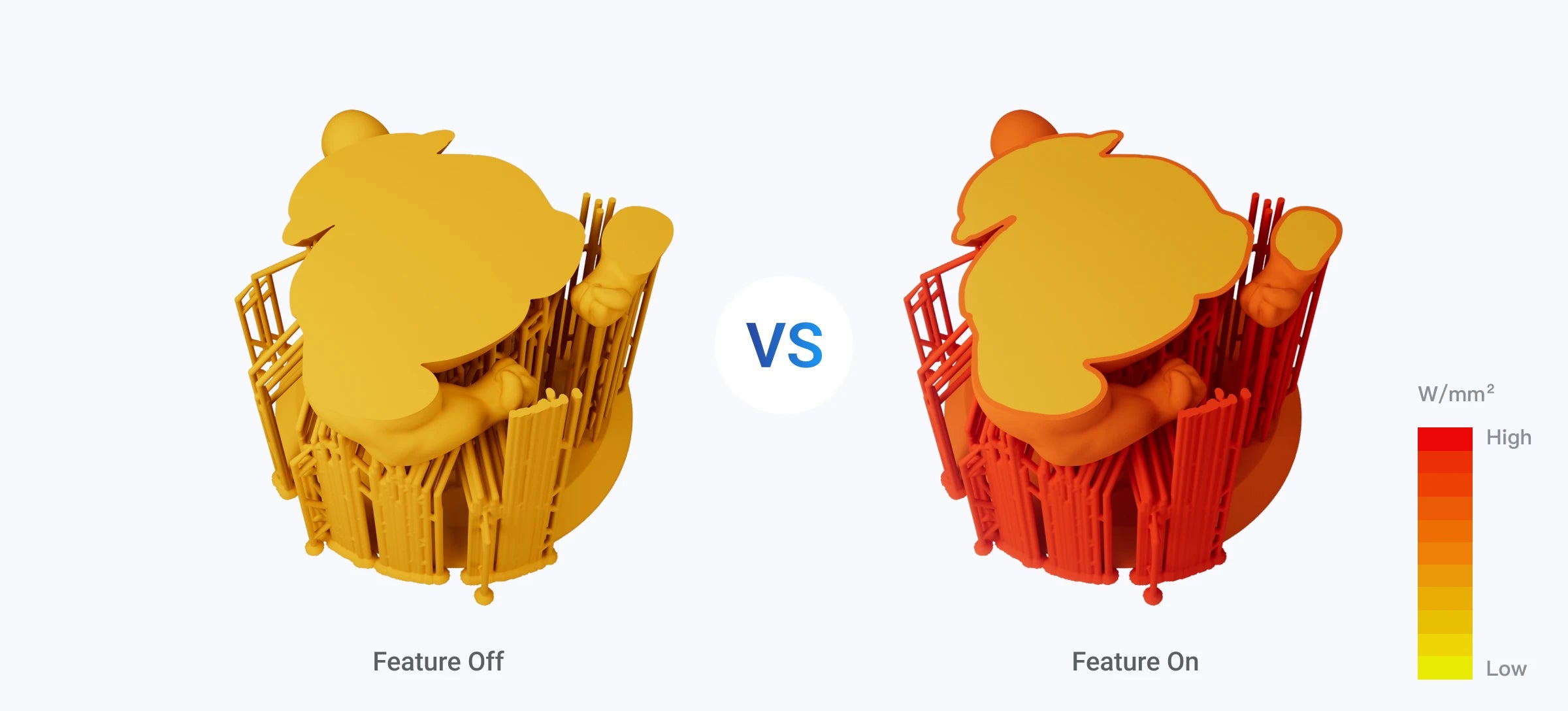

Intelligent Regional Exposure

By identifying various key regions of each layer, such as support structures as well as inner and outer shells, and curing them separately, Reflex significantly improves the surface hardness and support strength of prints, especially those printed with high-tensile-modulus materials*.

*Such as ABS-like resin, PVC-like resin, nylon-like resin, elastic resin, etc.

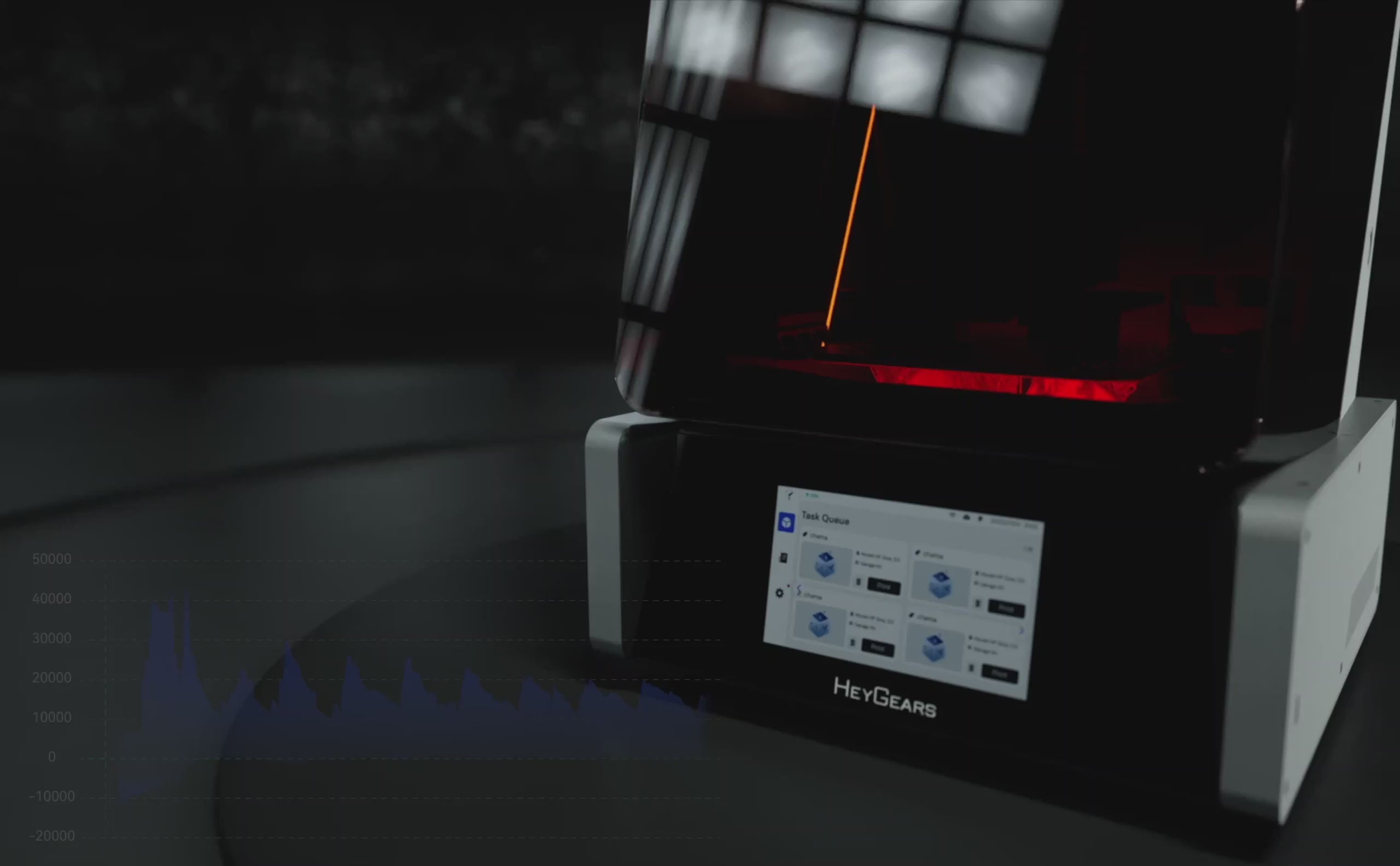

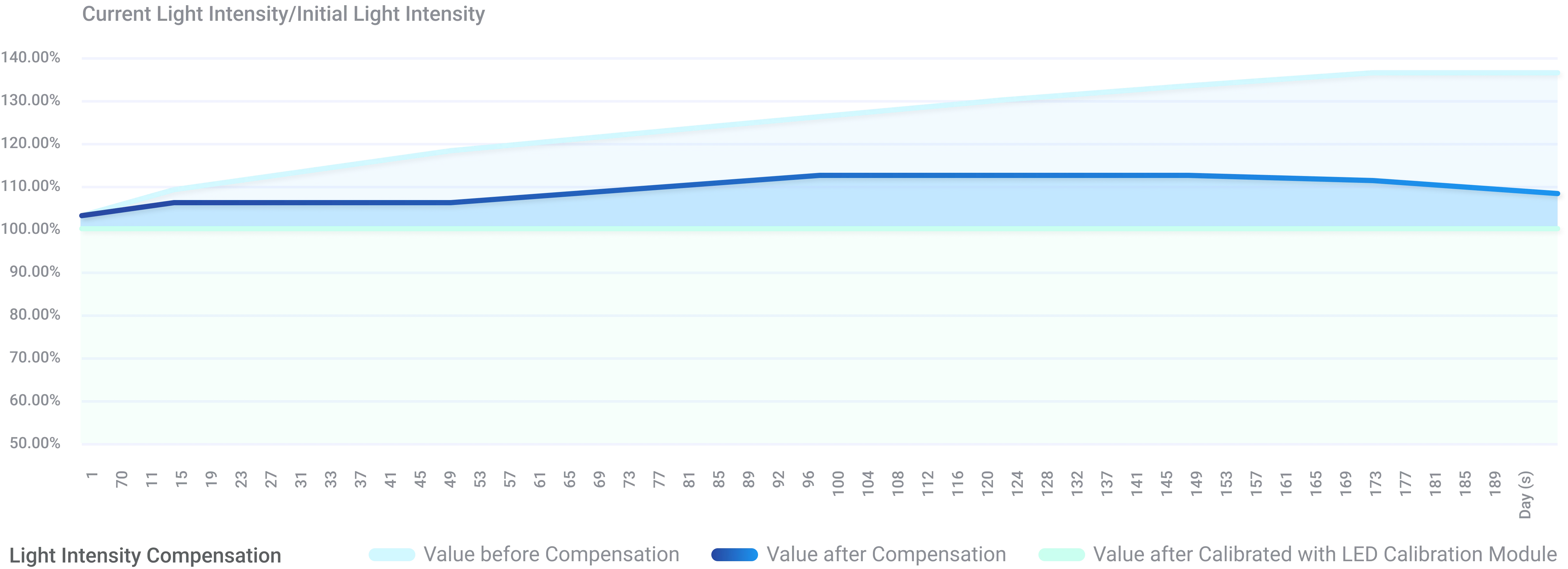

Printing Consistency During Printer Lifetime

By testing and recording the light source aging data, Reflex provides automatic light intensity compensation so users get consistent printing results during the whole printer life cycle.

Specifications

3D Printing Technology:

LCD (MSLA)

Build Volume:

191*121*220 mm

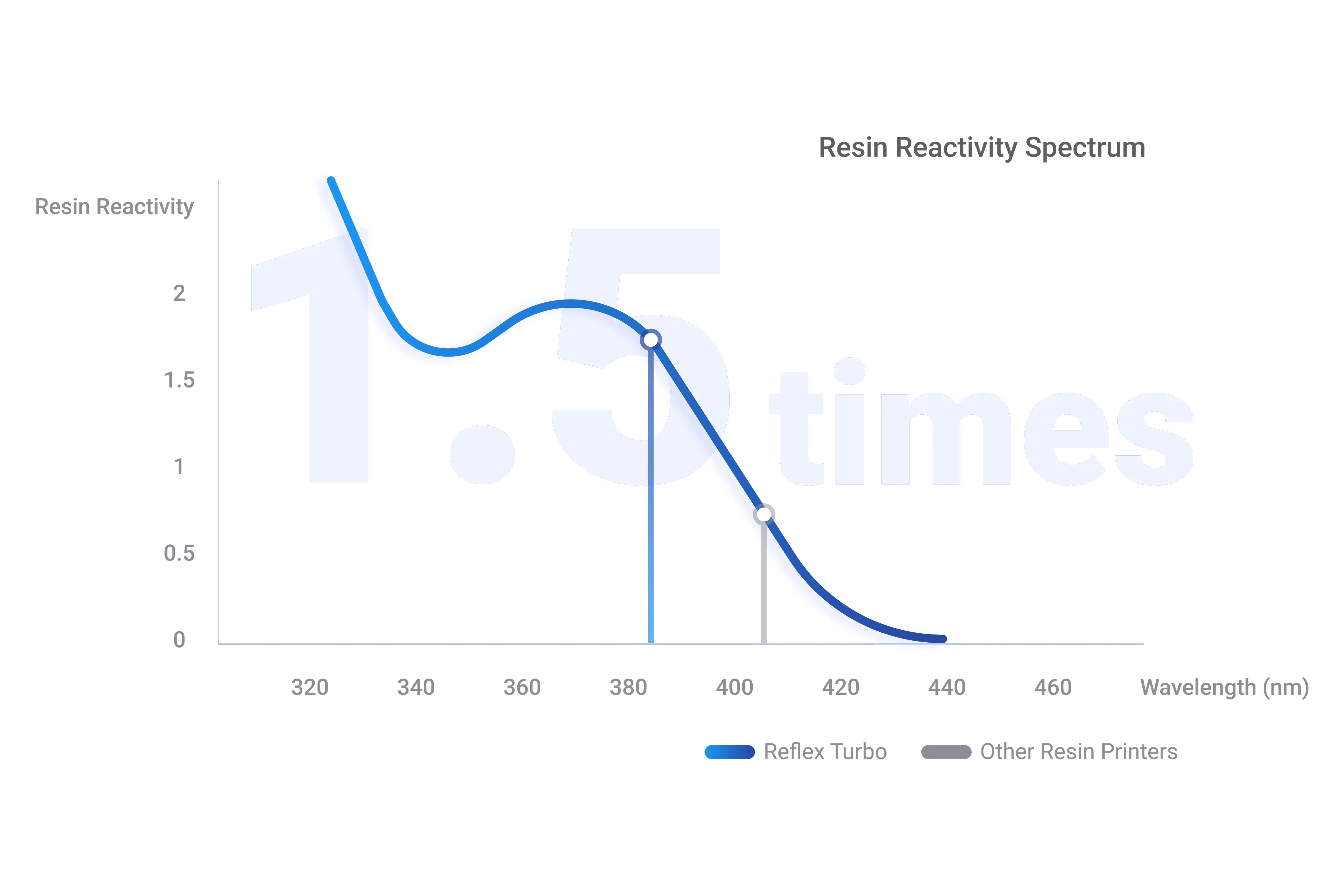

Optical Wavelength:

385+ nm

Build Height:

220 mm

XY Native Pixel:

33 μm

Accuracy:

±16 μm

Layer Thickness:

50 μm

Dimensions:

400*420*572 mm

Connectivity:

USB/WIFI/Ethernet

Weight:

25 kg

Voltage:

100-240 V~50/60 Hz

Rated Power:

350 W

Compatible Resin

All Resins

What's In the Box(Overview)

Printer X1

Power Cord X1

Resin Tank X1

Build Platform X1

LCD Screen Tape X1

Spare Release Film X1

Spare Screws for Release Film X2

Rubber Gloves X2

Allen Wrench X3

Part Removal Tool X1

Scraper X10

Pliers X1

Simple Cleaning Box X1

Filter Paper X5

Residue Remover X1

Multifunctional Handle X1

What's In the Box(Incomplete List)

Reflex Printer

Resin Tank

Build Platform

LCD Screen Tape

Spare Release Film

Resin Tank Sensor

Power

and more!

FAQs

Please read our FAQs page to find out more.

What is a resin 3D printer and how does it work?

Resin 3d printers offer higher resolution, better detail, and smoother surface finishes compared to FDM printers. They are also capable of producing complex geometries and intricate designs.

What types of resin are compatible with the UltraCraft Reflex 3D printer?

The UltraCraft Reflex 3D printer offers a wide range of compatible resins to cater to diverse printing needs. These include:

- PAS10 Standard Modeling Resin for general purpose modeling

- PAP10 Precise Detail Resin for intricate designs

- PAWW10 Water Washable Resin for easy post-processing

- PARP10 Rapid Prototyping Resin for quick prototyping

- PAH10 High-Temperature Resistance Resin for heat-resistant parts

- PAWR10 Wear-Resistant Resin for durable applications

- PAU10 ABS-like Resin for ABS-like properties

- PAT10 Transparent Resin for clear and translucent parts

- PAC10 Wax Casting Resin for lost wax casting

- PAM10 Design Resin for a balance of properties.

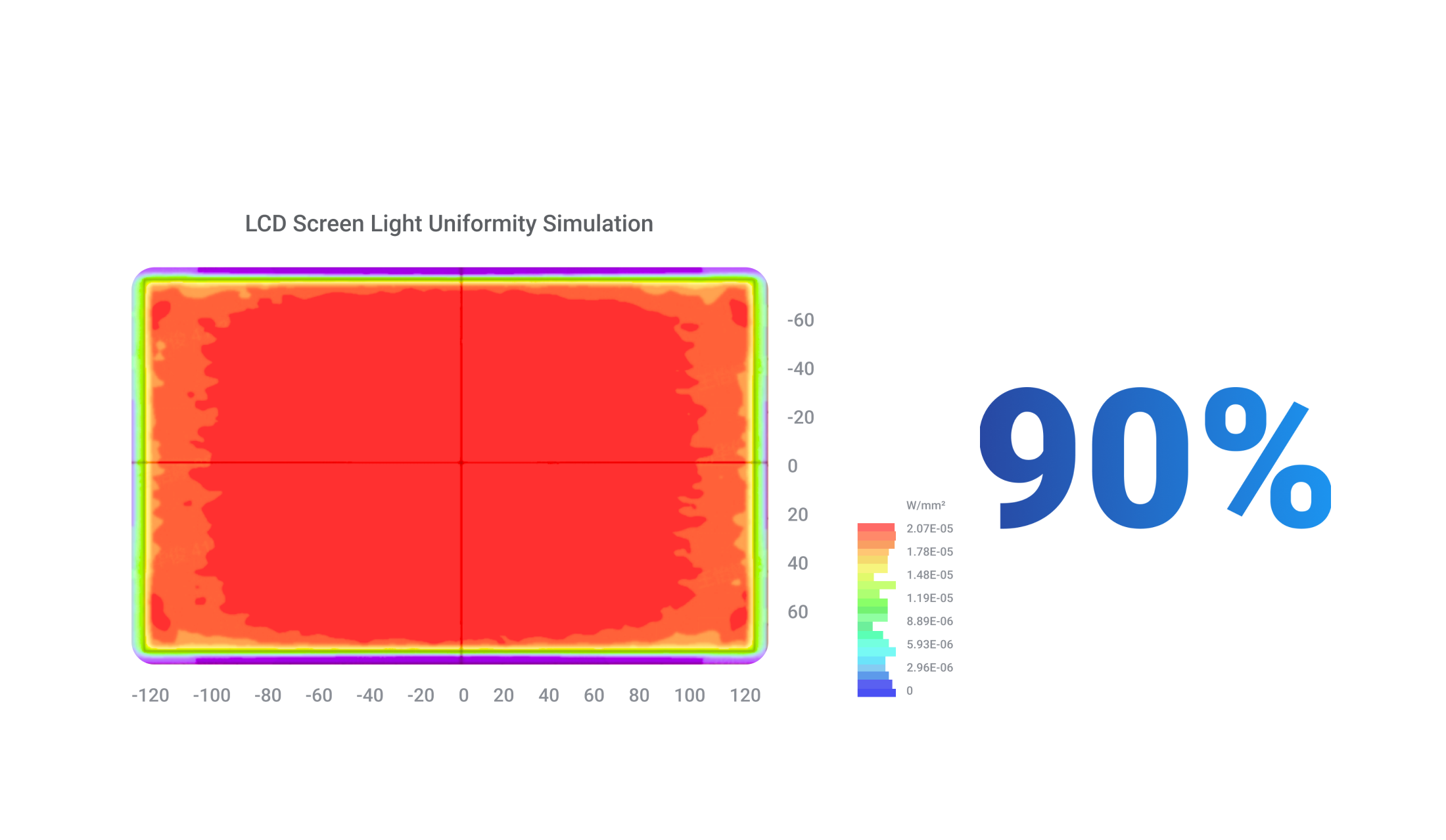

What type of light source is used on the UltraCraft Reflex 3D Printer?

HeyGears is the only brand in the industry that uses a self-developed 385+nm + COB light source and lens group, which delivers better light uniformity and collimation. Light sources with a shorter wavelength can also support higher-performance material curing.

How much tuning needs to be done before you can make your first print?

Before your first print, you need to select which resin you will use, the type of printed part, layer thickness, and other parameters that can be automatically set based on these selections. Other automatic features include auto-supports to make the preparation for printing as streamlined as possible. Once these steps are complete, you are ready to start your print.In some situations, such as low-temperature working environments requiring the heating of the print tray or if a 3D model needs to be repaired or adjusted before printing, the preparation time may be longer.

How do printing errors get fixed in the middle of a print?

HeyGears Blueprint printing software will be able to detect and analyze the model before the print to let the user know whether it is a printable structure.