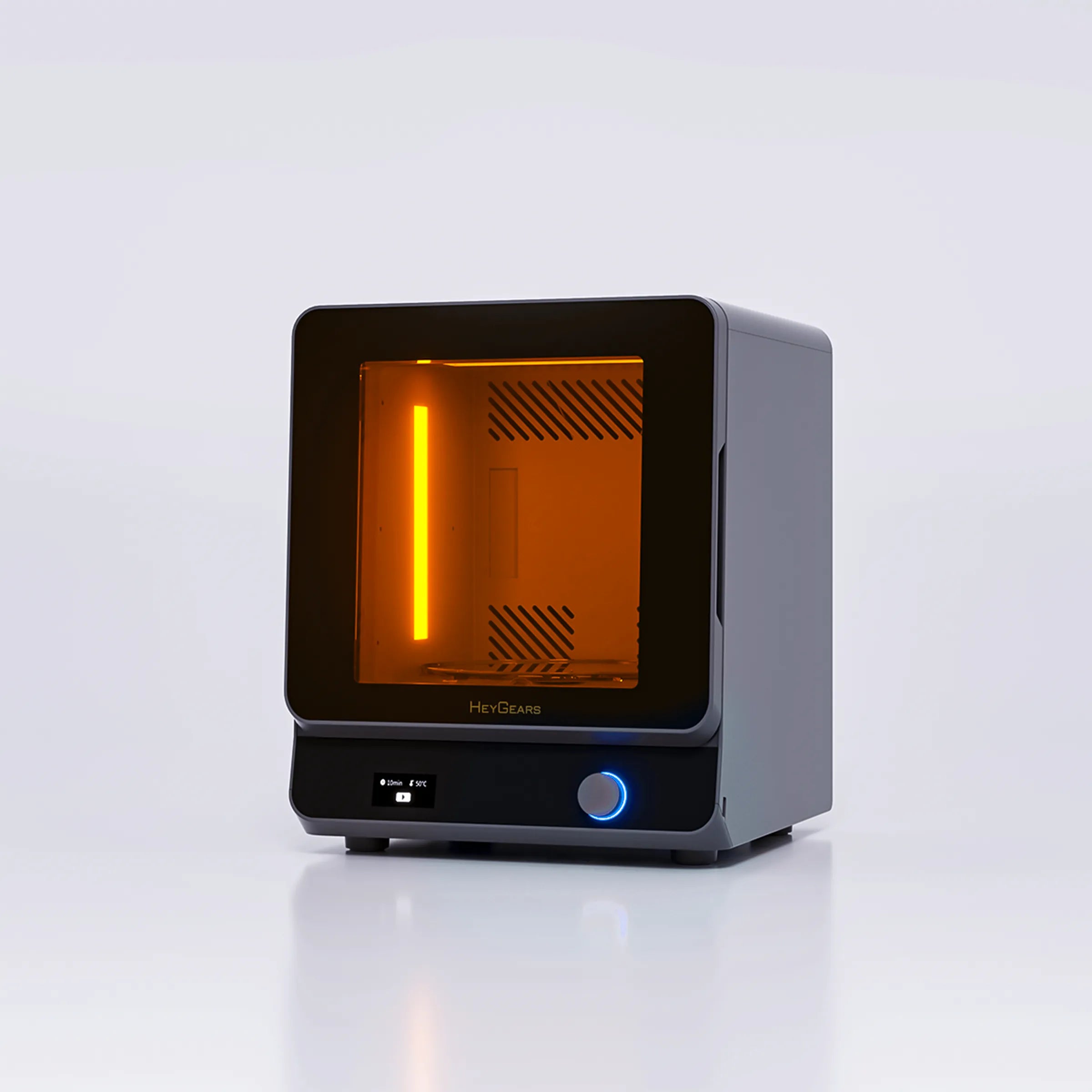

Experience fully integrated workflows—from printing to washing to curing—without the need for additional parameter adjustments.

Extra $50 Off Code: HG50NEW

New to HeyGears? Get $50 Off 3D Printers – Use Code: HG50NEW

(New users only. Valid for 3D printers.)

Product Highlights

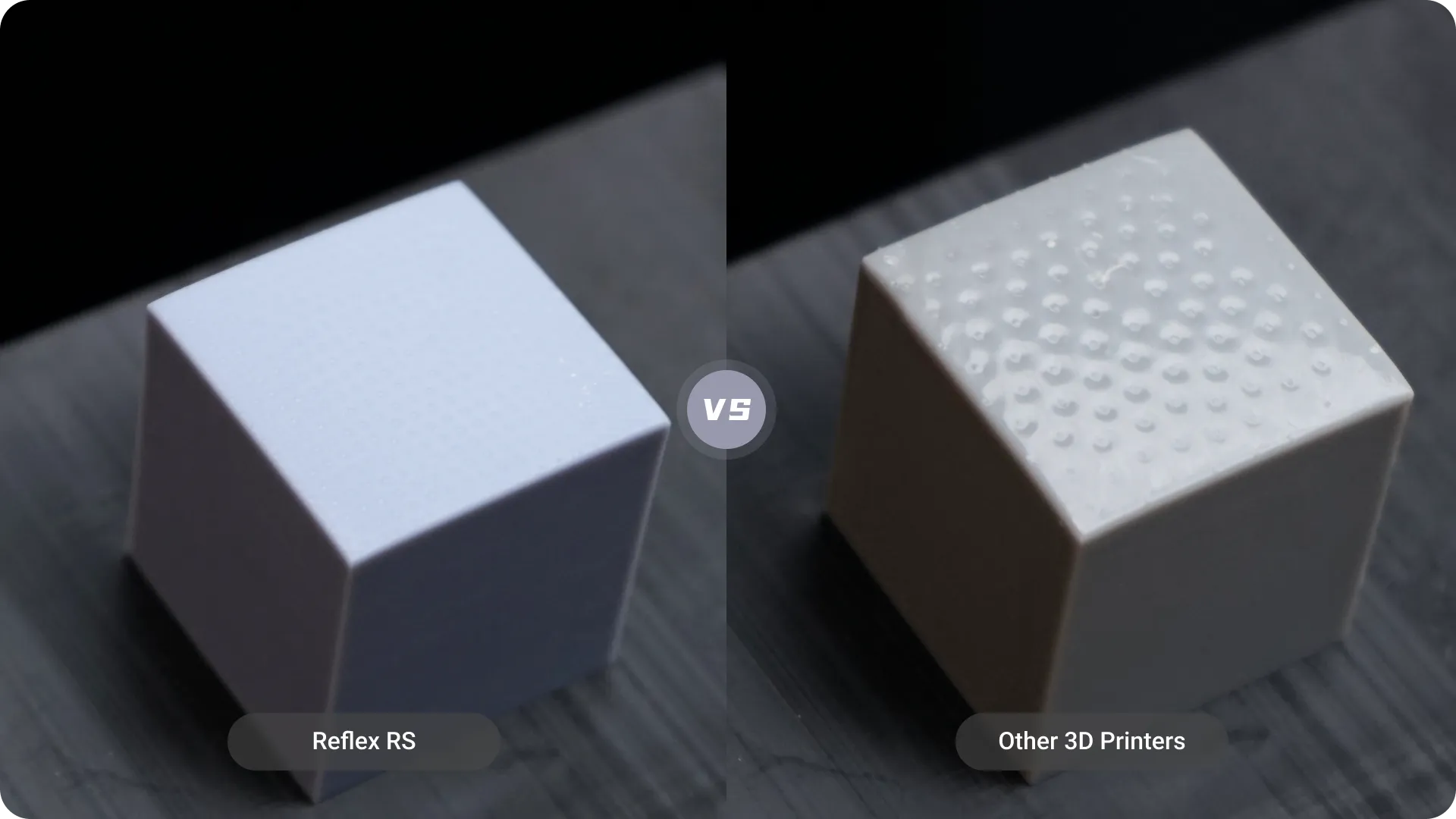

- Injection-molded Precision with 2 Hour Speed* (15 μm Precision).

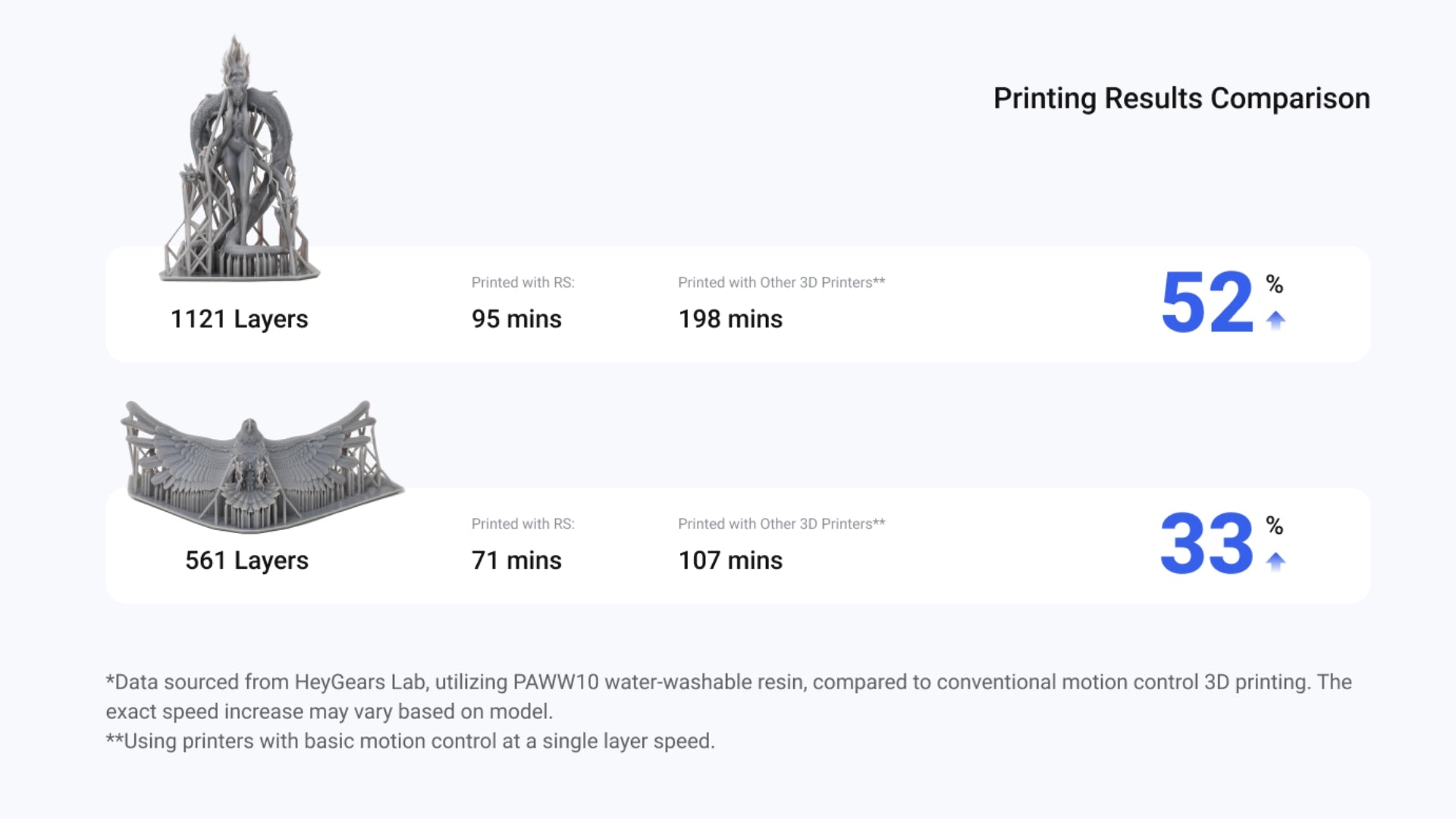

- Dynamic Motion Algorithm 3.0, 33% Increase in Print Speed.

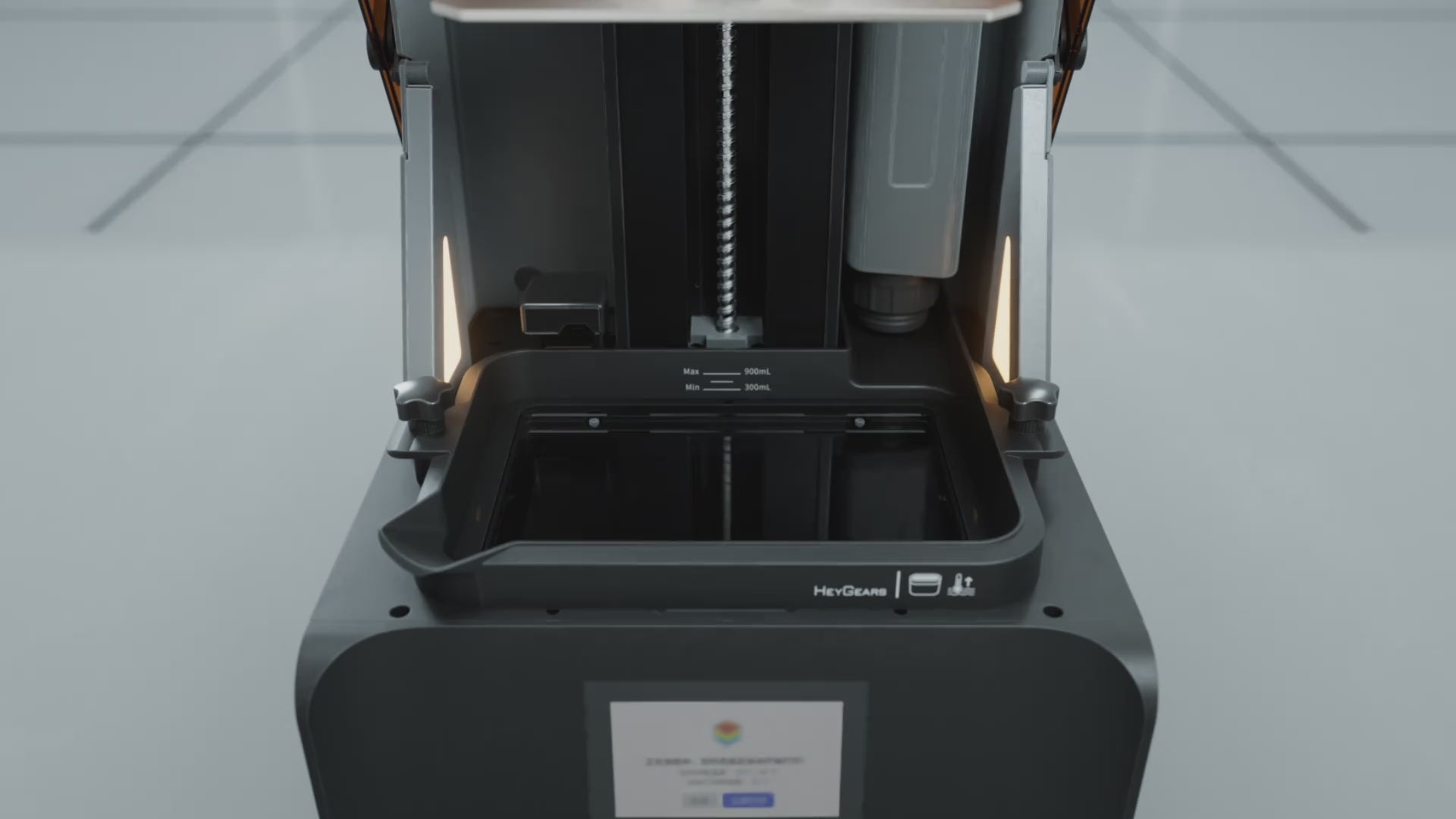

- Auto Resin Level Detection.

- UltraCraft Wash: Minimal Contact with Resin.

- UltraCraft Cure: Dual UV Wavelength Curing for Greater Material Performance. Extra Heating Function.

- Fully Interconnected Print Strategies. No Parameter Adjustments Throughout the Whole Process.

- Auto Assisted Printing:

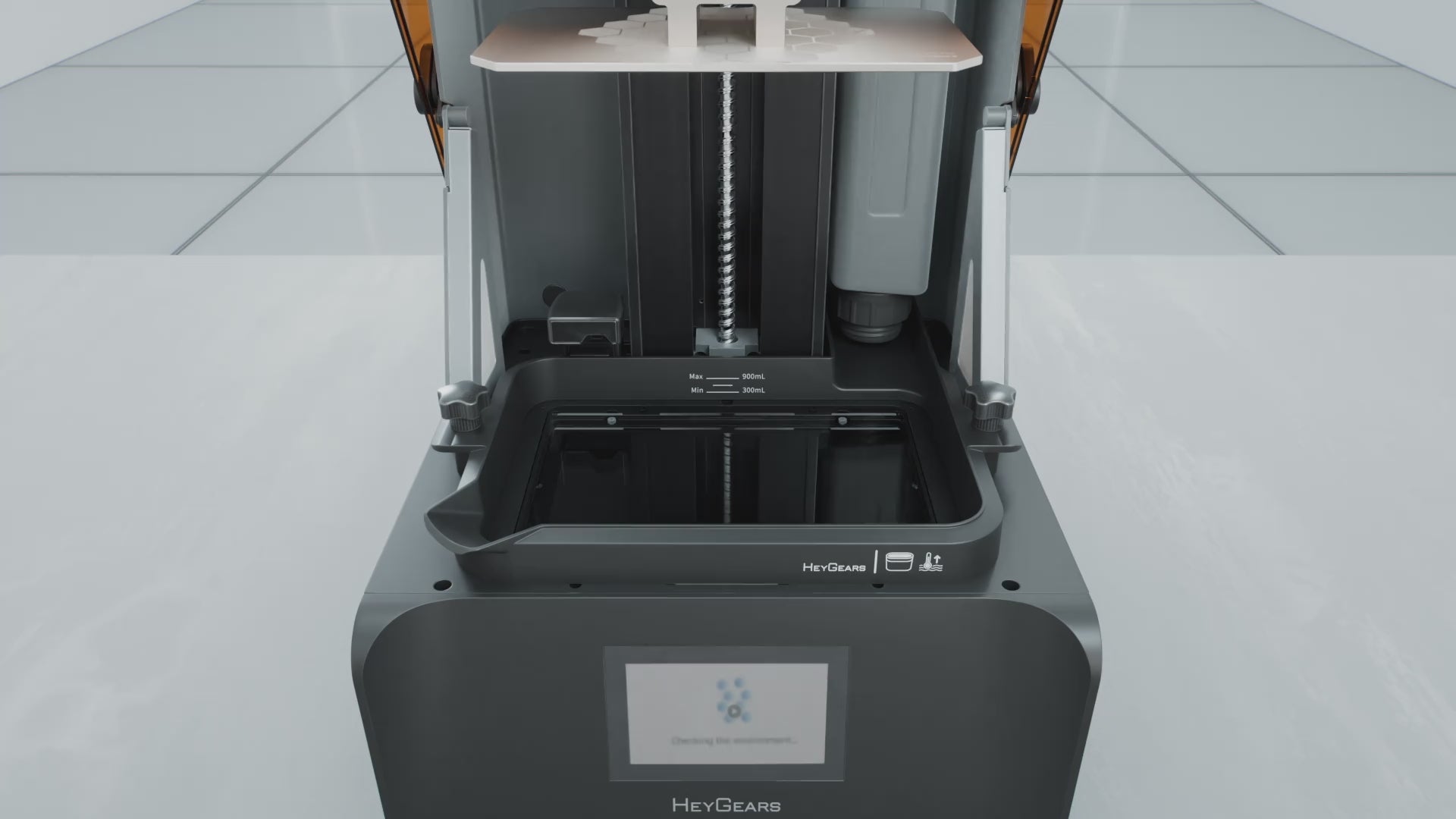

- Floating Screen Auto Leveling

- Automatic Resin Refill

- Automatic Resin Heating**

*Data sourced from HeyGears Lab, utilizing PAWW10 water-washable resin, compared to conventional motion control 3D printing. The exact speed increase may vary based on model.

** with RS Heated & Pulsing Release Resin Tank (purchased separately)

Package Includes

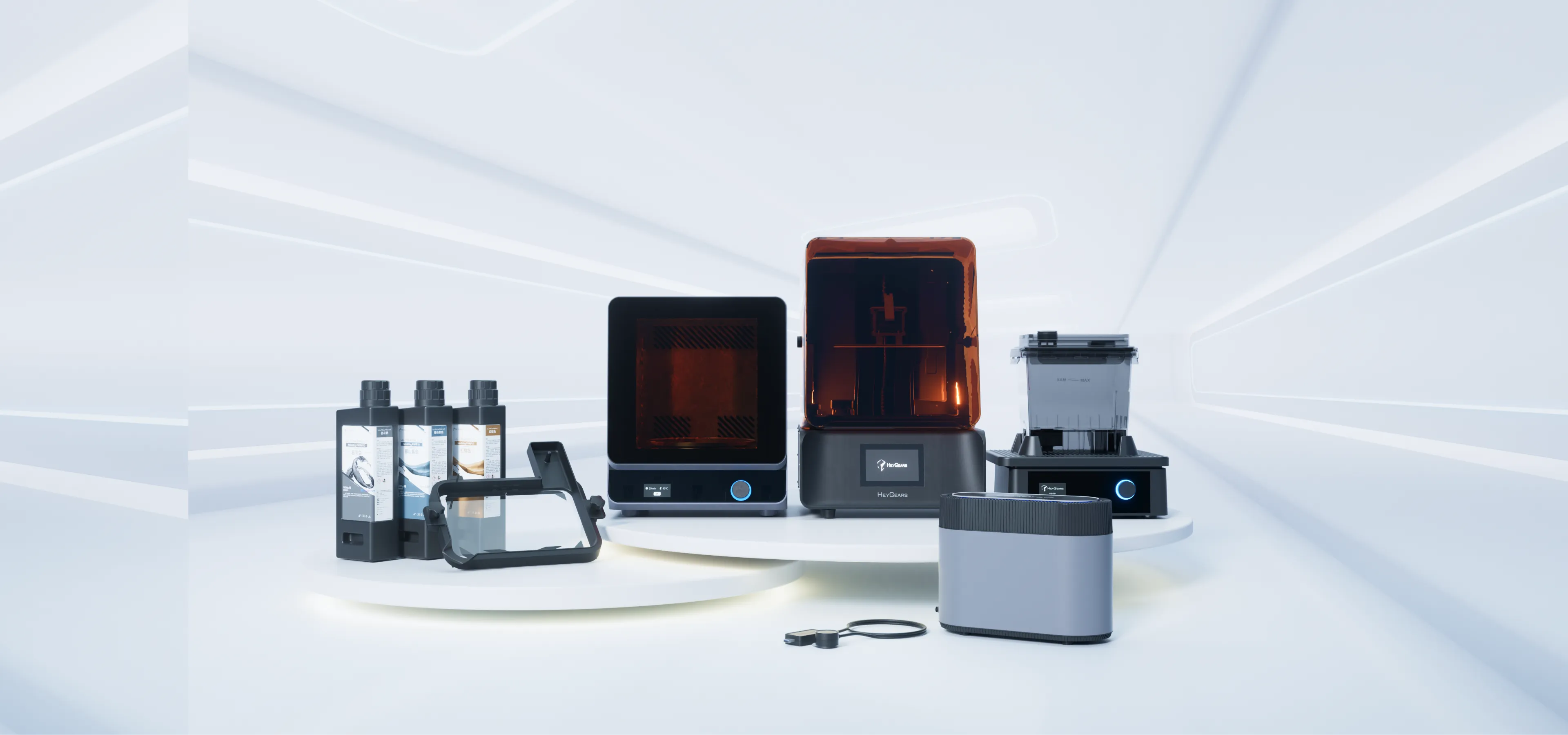

Reflex RS Combo:

UltraCraft Reflex RS 3D Printer x1

UltraCraft Wash x1

UltraCraft Cure x1

Reflex RS Combo with Pulsing Release Module :

UltraCraft Reflex RS 3D Printer x1

UltraCraft Wash x1

UltraCraft Cure x1

UltraCraft Pulsing Release Module x1

UltraCraft Reflex RS Heated & Pulsing Release Resin Tank x1

Pairs well with

Reflex RS Combo

We're committed to providing you with the best service. Please don't hesitate to reach out if you have any questions.

-

Shipping Information

Free shipping on orders over $399. Click here for more shipping details.

-

Customer Support

Need assistance? We are here to help!

WhatsApp:

+1 949-283-2998(US)

Mon-Fri, 9AM-5PM PSTEmail Support:

contact@heygears.com

Technical Support:

customersupport@heygears.com

-

Get Started

Getting Started with Your HeyGears 3D Printer

-

FAQ’s

Please read our FAQs page to find out more.

Hear It From Our Users

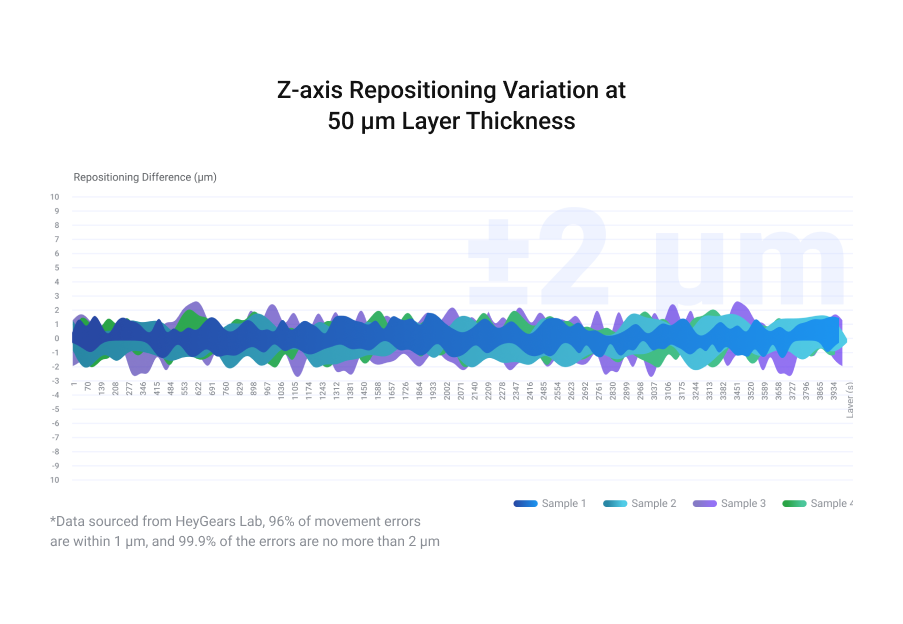

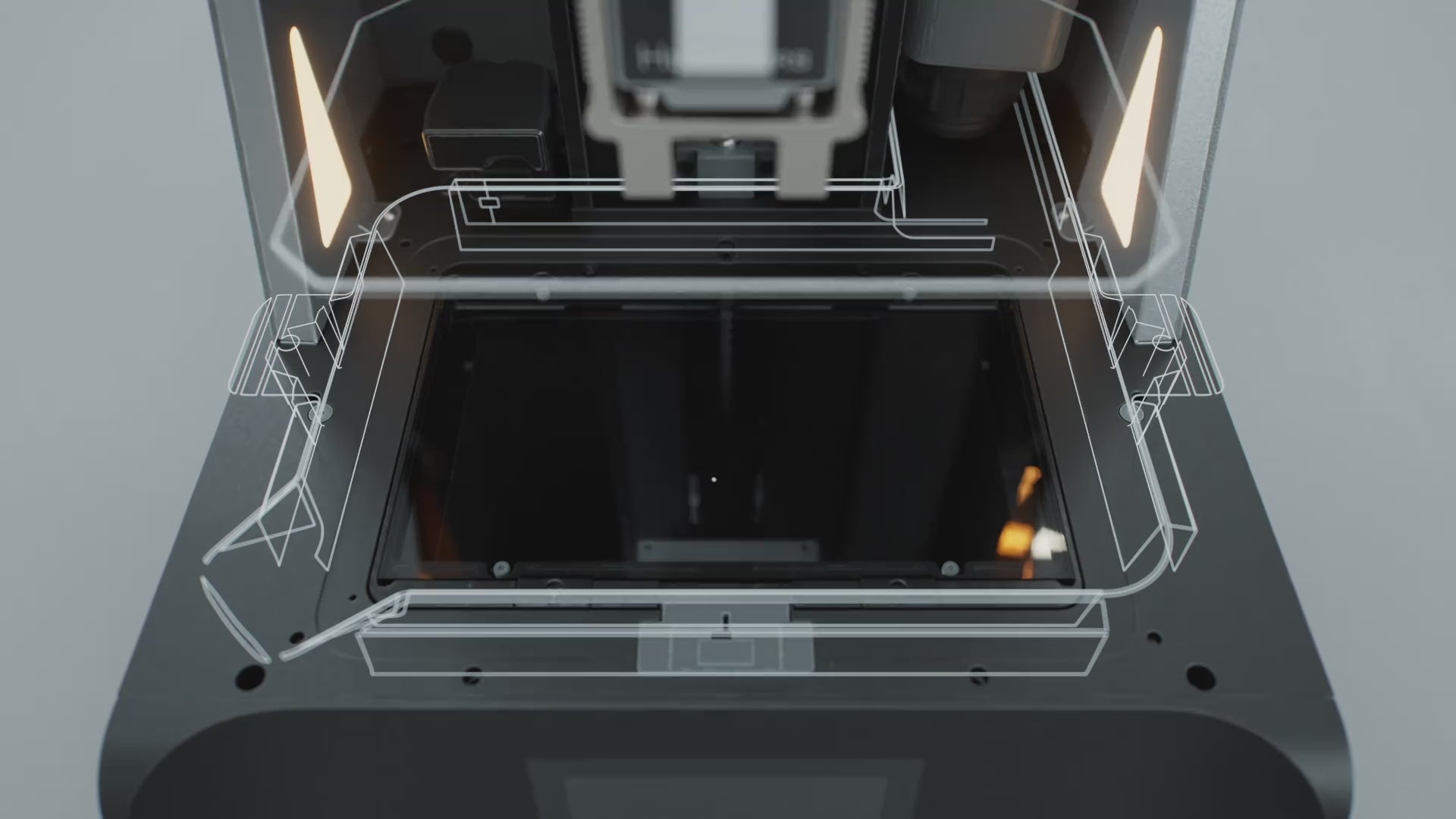

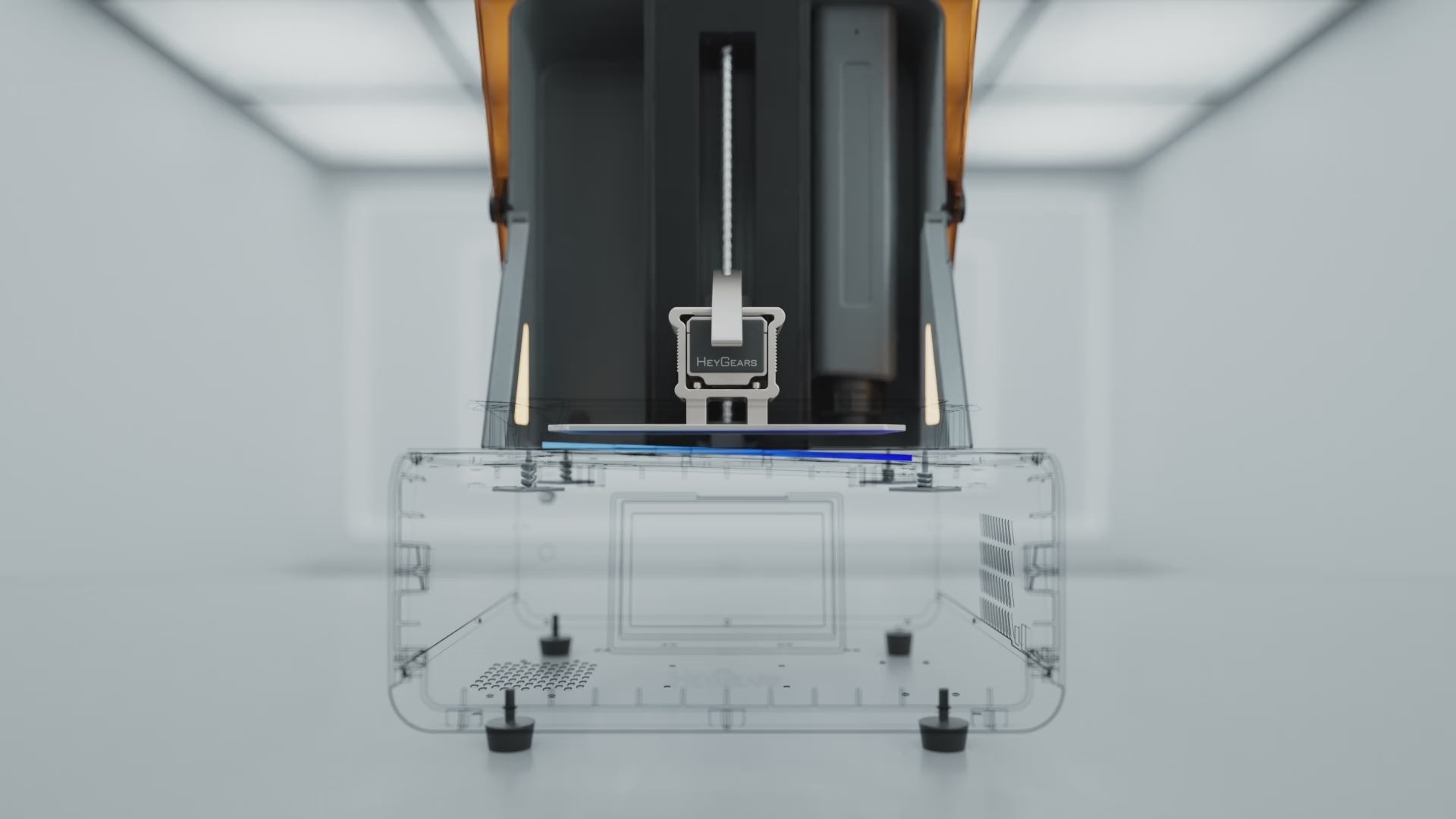

Reliable C5 grade Z-axis Module

High repeat positioning accuracy ensures layer positioning errors are no more than 2 μm*. Tested with a 50 kg load across ten thousand runs.

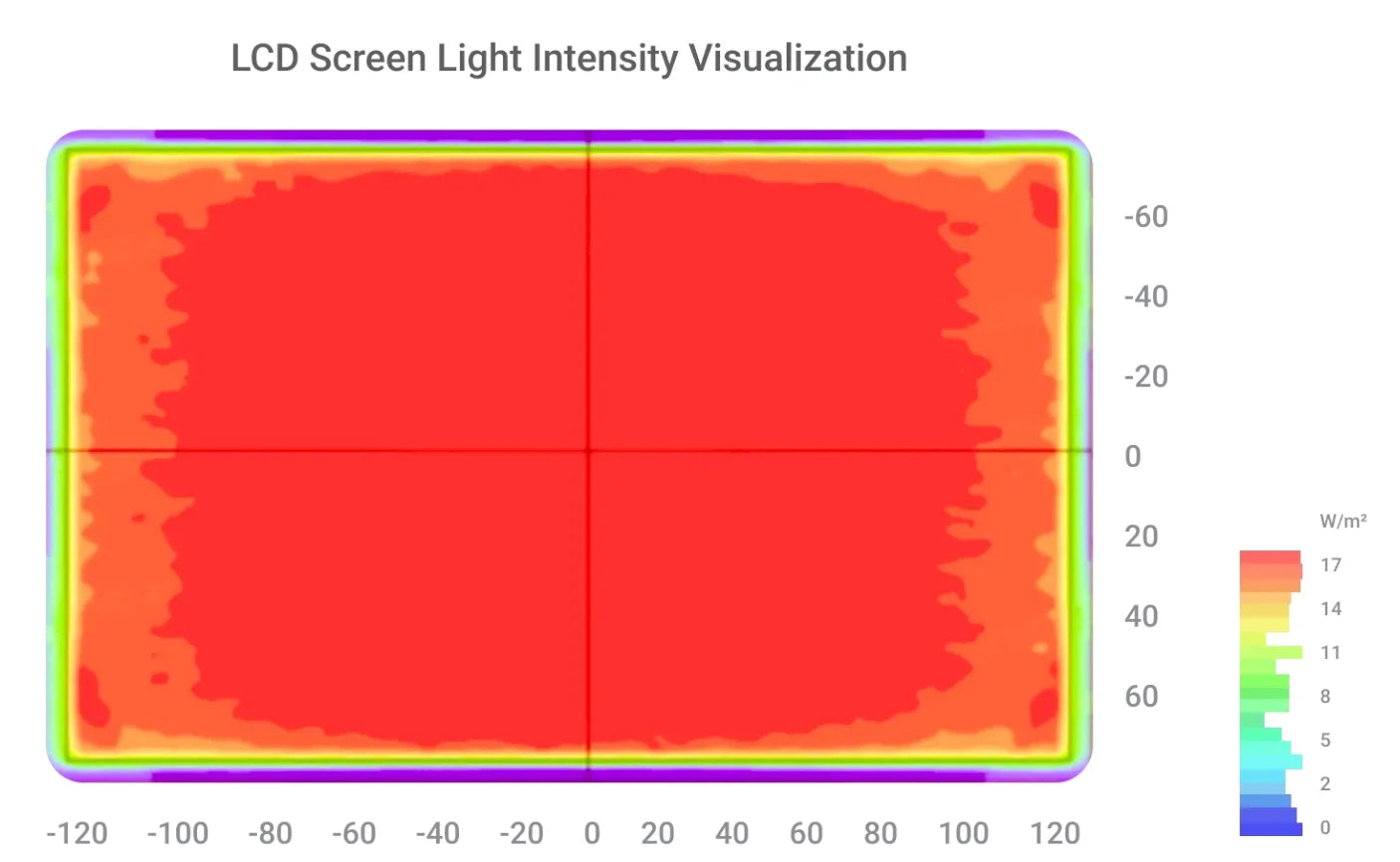

Full-Field Precision Screen

Adaptive Z-axis Compensation

Dynamic Motion Algorithm 3.0, 33% Increase in Print Speed*

*Data sourced from HeyGears Lab, utilizing PAWW10 water-washable resin, comparedto conventional motion control 3D printing. The exact speed increase may vary based on model.

A Complete Production System

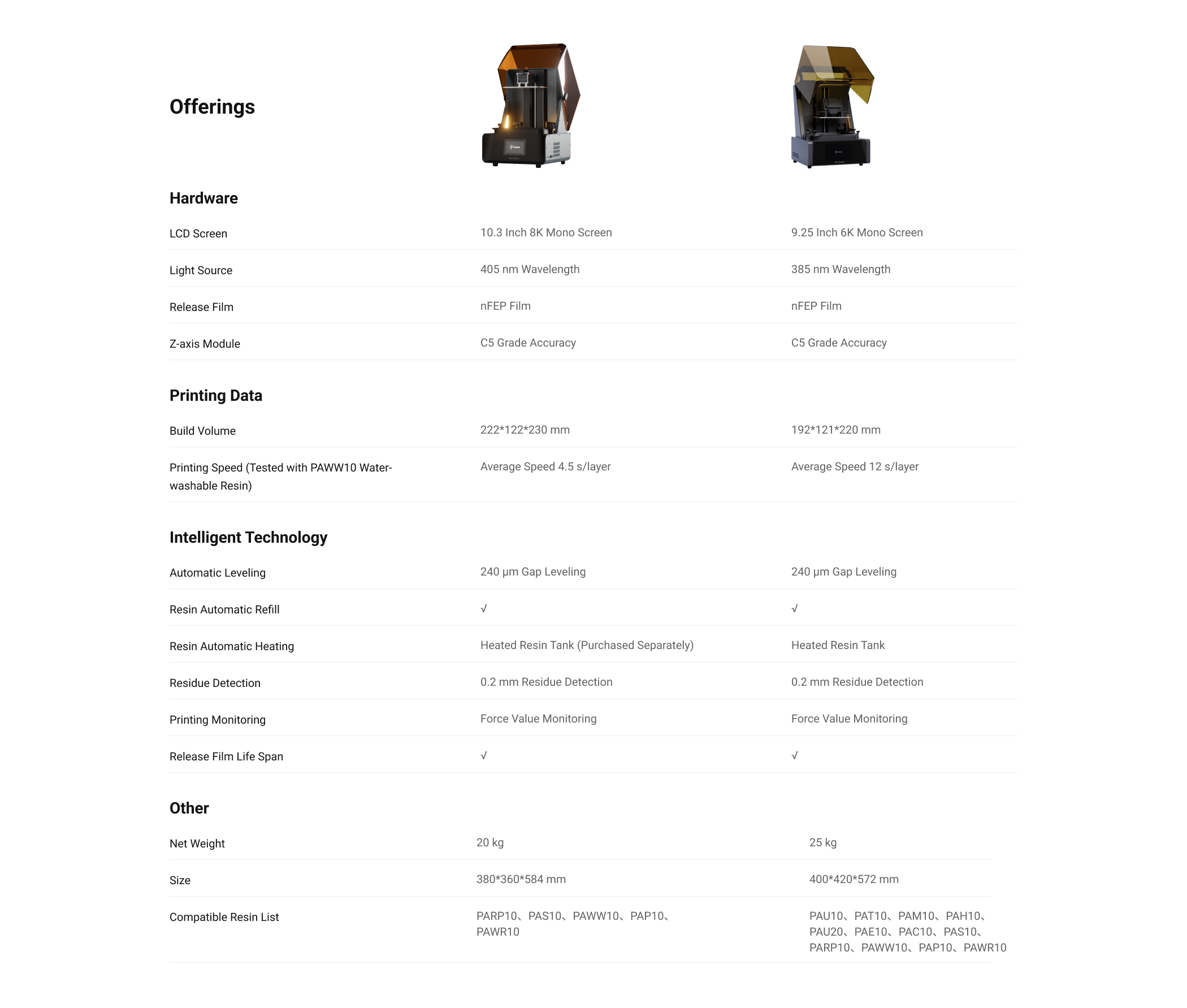

Specifications

3D Printing Technology:

LCD (MSLA)

Build Volume:

222*122*228 mm

LCD Screen

10.3 Inch 8K Mono Screen

Light Source:

405 nm

Z-axis Module:

C5 Grade Accuracy

XY Native Pixel:

29.7 μm

Accuracy:

±15 μm

Layer Thickness:

30-100 μm

Size:

380*360*584 mm

Weight:

20 kg

Rated Power:

180 W

Voltage:

100-240 V~50/60 Hz

Size:

380*360*584 mm

Connectivity:

USB/WIFI

Language:

English, Simplified Chinese,Japanese

Compatible Resin

PARP10、PAS10、PAWW10、PAP10、PAWR10

Included in the Box

Printer

Power Cord

Part Removal Tool

Resin Tank

Build Platform

Allen Wrench

Scraper

FAQs

Please read our FAQs page to find out more.

What is the optimal temperature for 3D printing?

It is recommended to maintain the resin temperature at 20-25°C during printing. This temperature range helps the resin to retain good flowability and curing characteristics, thereby ensuring the stability of the printing process and the quality of the final product.

Are the pulse modules of the Reflex RS the same as those of the Reflex? Can they be used interchangeably?

The pulse modules consist of a pulse main unit and a pulse resin tank. The pulse main units for the Reflex RS and Reflex are the same, but the pulse resin tank sizes are different and therefore not interchangeable.

Is it necessary to use RS in a ventilated environment?

It is recommended to use it in a well-ventilated environment, which helps with equipment cooling and is also beneficial for dispersing the smell of the resin.

Can the Reflex RS use third-party resins for printing?

To ensure the quality of prints and the stability of the equipment, it is recommended to use resins provided by the official source. Our resins have undergone rigorous testing to ensure they are perfectly matched with the printer's performance and software settings, resulting in high-quality prints.If you use resins from other brands, mismatched parameters may lead to risks such as print detachment, missing parts, residue, poor surface quality, low precision, and could even damage the equipment. Damage to the printer caused by third-party resins is not covered under warranty.

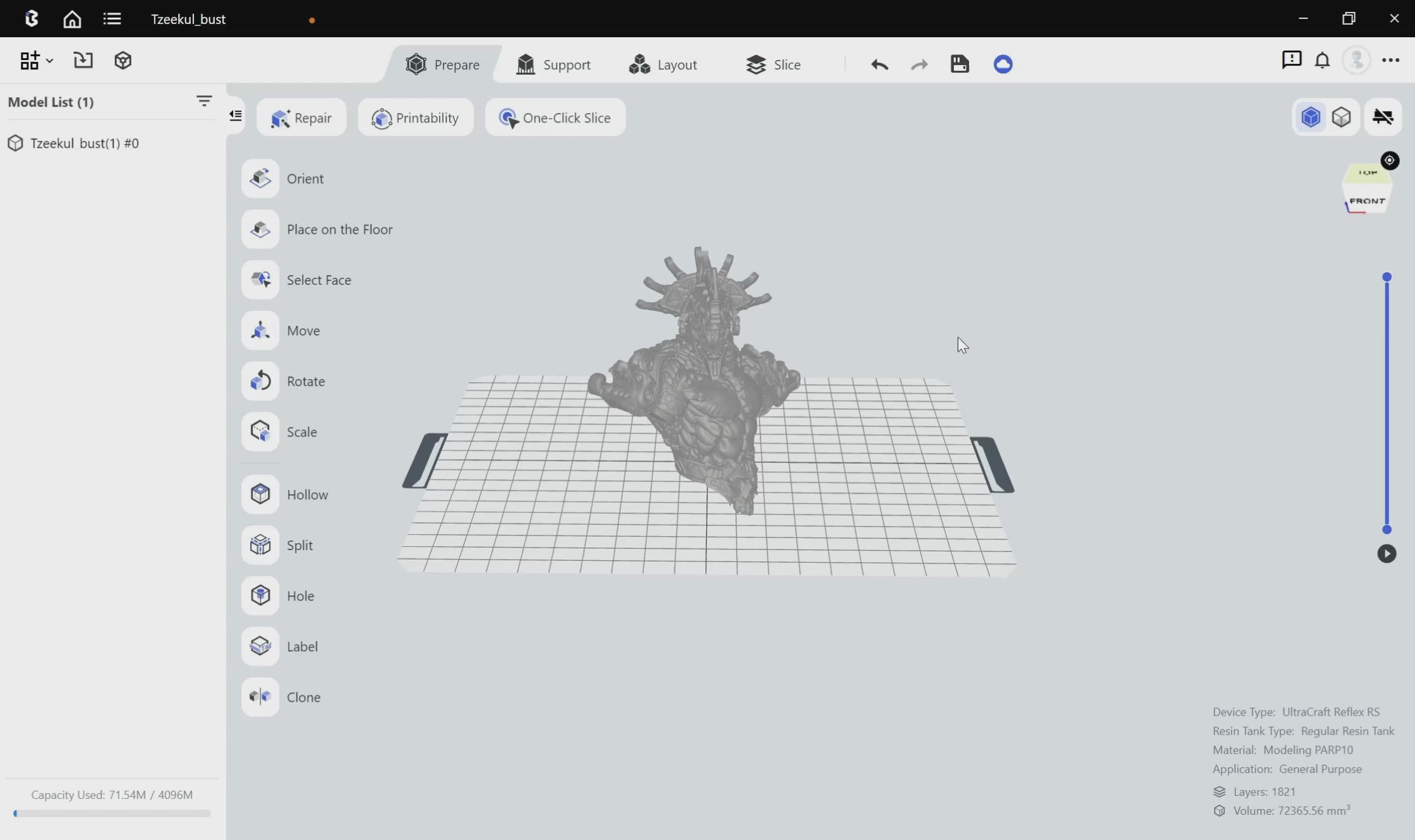

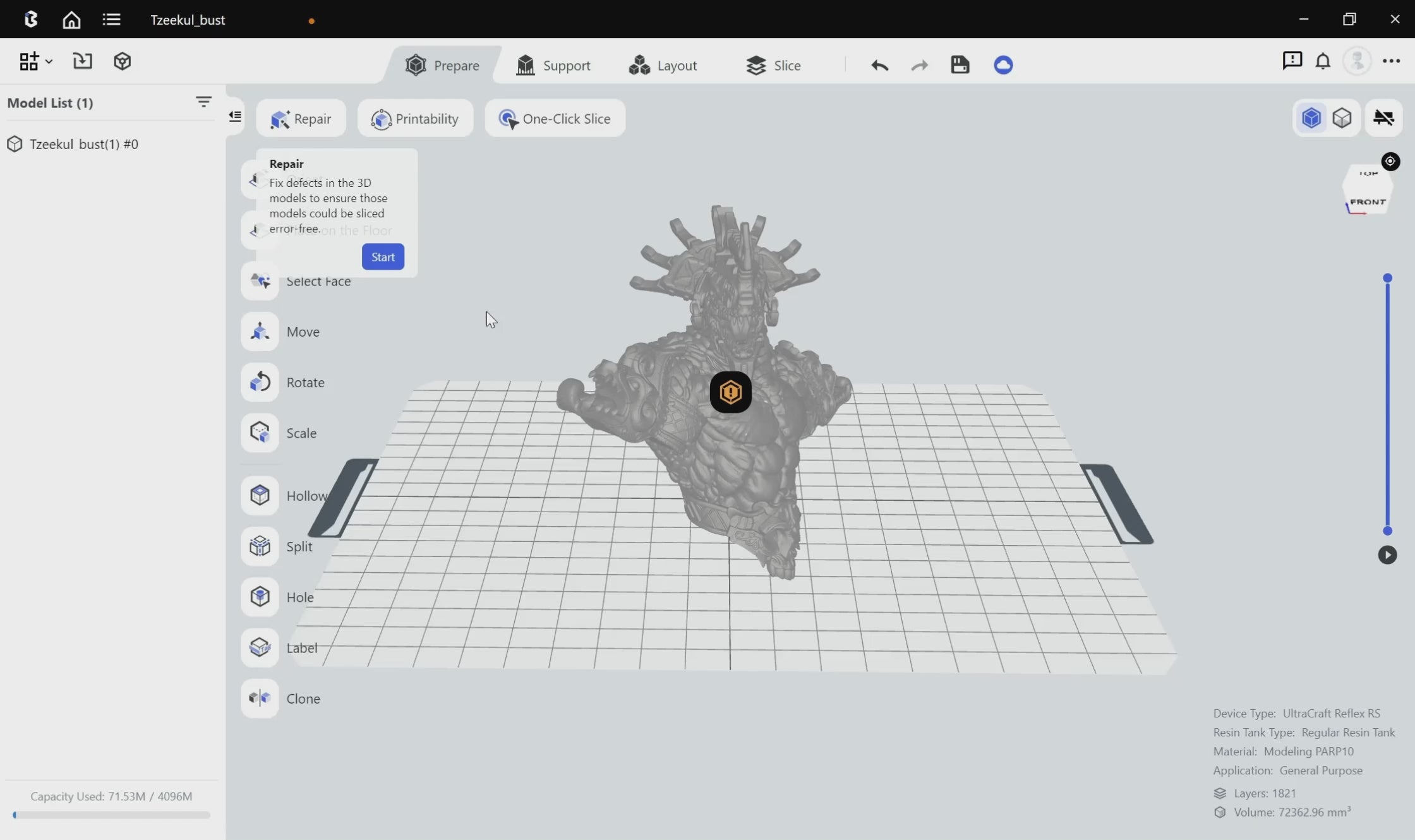

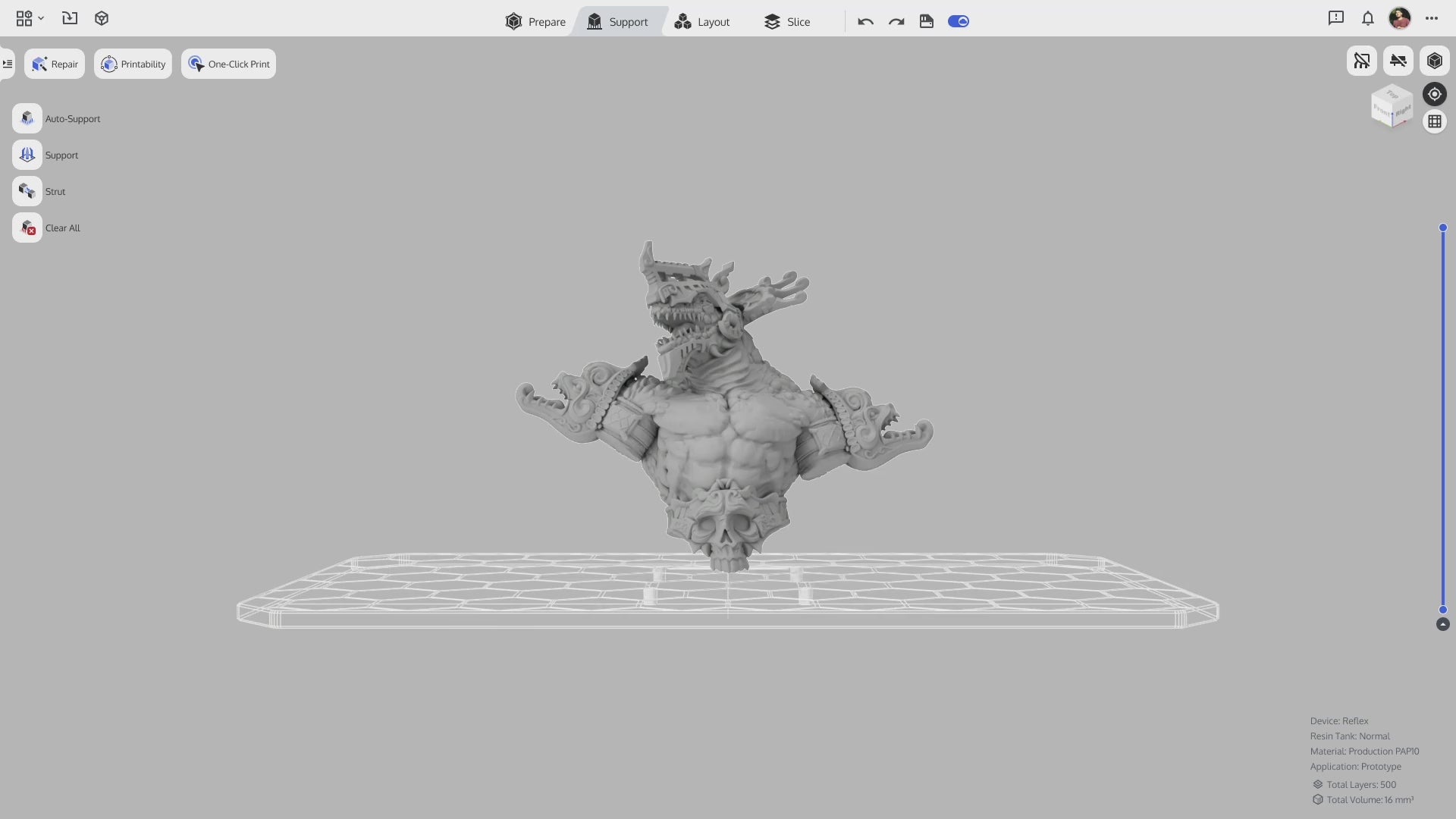

Can Reflex RS use third-party slicing software files for printing?

Currently, Reflex RS can only use the slicing files provided by BPS. This is to ensure print quality and printer compatibility. The official slicing software is professionally designed and optimized to intelligently adjust and set according to different models and materials, allowing users to easily print high-quality works. Using non-official slicing software may lead to printing failure or quality issues. Therefore, we recommend using the official slicing software for the best printing experience.