The question of "how much are 3D printers?" is complex, with answers spanning a vast financial spectrum. While the additive manufacturing landscape includes various technologies, resin 3D printing—encompassing Stereolithography (SLA), Digital Light Processing (DLP), and Masked Stereolithography (MSLA)—has carved out a distinct and vital niche. Unlike its filament-based counterpart, Fused Deposition Modelling (FDM), which is often favoured for its affordability and production of robust, functional parts, resin printing is the undisputed leader for applications where microscopic detail, smooth surface finishes, and intricate geometries are paramount. The price of a resin 3D printer can range from less than $200 for a machine aimed at beginners to well over $10,000 for sophisticated industrial systems.

This guide provides a comprehensive breakdown of the resin 3D printer market, segmenting it into three distinct tiers: entry-level, prosumer/mid-range, and professional grade. By examining the price points, features, and ideal users for each category, prospective buyers can make an informed decision. Furthermore, this analysis extends beyond the initial hardware investment to explore the total cost of ownership—a critical consideration that includes ongoing expenses for materials, mandatory post-processing equipment, and long-term maintenance. Understanding these factors is essential for anyone looking to harness the power of high-fidelity 3D printing, whether for personal passion projects or professional production.

The Entry-Level Tier: Your First Step into High-Detail Printing

The entry-level tier represents the most accessible gateway into the world of high-resolution resin 3D printing. This market segment has been revolutionized by advancements in manufacturing that have made once-premium technology widely available, allowing hobbyists and newcomers to produce stunningly detailed objects on a modest budget.

Price Range: What to Expect for a Beginner Resin 3D Printer

For those just beginning their journey, the initial investment is surprisingly low. Entry-level resin 3D printers typically fall within a price range of $150 to $500. Numerous sources confirm this accessible starting point, with some capable models available for as little as $160 to $179. The general market consensus places the starting line for a reliable beginner machine between $200 and $300. The upper end of this tier, approaching $500, usually includes newer models that offer slight improvements, such as a marginally larger build plate or a screen with a higher initial resolution.

Key Features

The primary technology found in this tier is almost exclusively Masked Stereolithography (MSLA). This process uses a powerful UV light source that shines through a liquid crystal display (LCD) screen, which acts as a mask to cure an entire layer of liquid resin at once. The widespread availability and falling cost of monochrome LCD screens have been the principal drivers behind the affordability of this market segment.

The main selling point of these machines is their exceptional resolution. It is common for entry-level printers to feature 4K, 8K, or even higher resolution screens. Because these high-resolution screens are paired with a small build area, the resulting pixel size (XY resolution) is minuscule, allowing for the creation of intricate details that can surpass those produced by even high-end FDM printers.

However, this impressive detail comes with a significant trade-off: build volume. The printable area on these machines is typically small, making them ideal for projects like tabletop miniatures, jewelry components, or small-scale prototypes, but unsuitable for large objects. The user experience, while dramatically improved in recent years, still often requires a hands-on approach. Build plate levelling is frequently a manual process, and the machines may require more frequent calibration and fine-tuning to achieve consistent results.

Who Should Consider an Entry-Level Model?

This tier is perfectly suited for several user groups:

-

Hobbyists and Makers: Individuals passionate about creating detailed miniatures for tabletop games, intricate figurines, and other personal projects where fine detail is the highest priority.

-

Students and Educators: These printers serve as an affordable and effective tool for introducing students to the principles of high-resolution additive manufacturing.

-

Jewelry Designers and Artisans: For those on a budget, these machines provide a low-cost method for prototyping complex jewelry designs and creating patterns for investment casting.

-

Budget-Conscious Beginners: Anyone who wishes to explore the capabilities of resin printing without a significant financial commitment and is willing to invest the time to learn the hands-on aspects of the technology will find this tier to be an excellent starting point.

The existence of this vibrant entry-level market can be traced directly to the maturation of monochrome LCD technology. Early resin printers were hindered by slow cure times and screens with very short operational lifespans. The shift to monochrome LCDs marked a significant technological leap, enabling much faster curing (as they block less UV light) and offering thousands of hours of operational life, a dramatic improvement over their predecessors. As the manufacturing of these screens scaled up, their costs fell, directly fueling the explosion of the sub-$500 resin printer category. This has led to intense competition, where features like 8K resolution, once reserved for premium machines, are now standard, setting an incredibly high baseline for quality at an affordable price.

The Prosumer & Mid-Range: Balancing Performance and 3D Printer Cost

Bridging the gap between casual hobby use and dedicated professional production, the prosumer and mid-range tier of resin 3D printers offers a compelling blend of advanced features, increased reliability, and a larger canvas for creation. This segment is designed for users who have moved beyond the basics and now require greater performance and consistency from their equipment.

Price Range: Investing in Advanced Capabilities

The investment for a prosumer or mid-range resin 3D printer typically ranges from $500 to $3,000. This bracket is well-established, with various market analyses identifying a "hobbyist" or "mid-range" tier starting around $500 and extending to $1,500 or $3,000. The upper end of this range overlaps with the entry point for professional desktop machines, which begin around $2,000 to $2,500, signifying a transition towards more business-oriented features and reliability.

What a Higher Cost Gets You: Speed, Size

The step up in price delivers tangible upgrades across several key areas. The most significant differentiator is a larger build volume. This allows users to either print much larger single objects or to batch-produce numerous smaller items simultaneously, dramatically increasing productivity and throughput.

This larger build area is typically paired with larger monochrome screens. While the individual pixel size might be comparable to some entry-level models, the ability to maintain that extreme level of detail across a much larger surface is a substantial upgrade. Combined with more powerful UV light engines, these printers achieve very high printing speeds.

Beyond size and speed, the investment translates into superior build quality and reliability. These machines often feature more robust mechanical components, such as dual linear rails or industrial-grade ball screws for the Z-axis. This enhanced construction minimizes vibration and Z-wobble, leading to greater print consistency and reliability over thousands of hours of operation.

Perhaps most importantly, this tier introduces a host of quality-of-life and automation features that transform the user experience from one of manual "tinkering" to streamlined "producing." Common advancements include:

-

Automatic build plate levelling systems.

-

Heated resin vats that maintain the optimal viscosity for consistent printing, a crucial feature when working with more demanding engineering resins.

-

Integrated air purification systems to manage the odour associated with photopolymer resins.

-

Wi-Fi connectivity for remote print management and monitoring via desktop or mobile applications.

-

Intelligent systems, such as automatic resin level detection and refilling mechanisms.

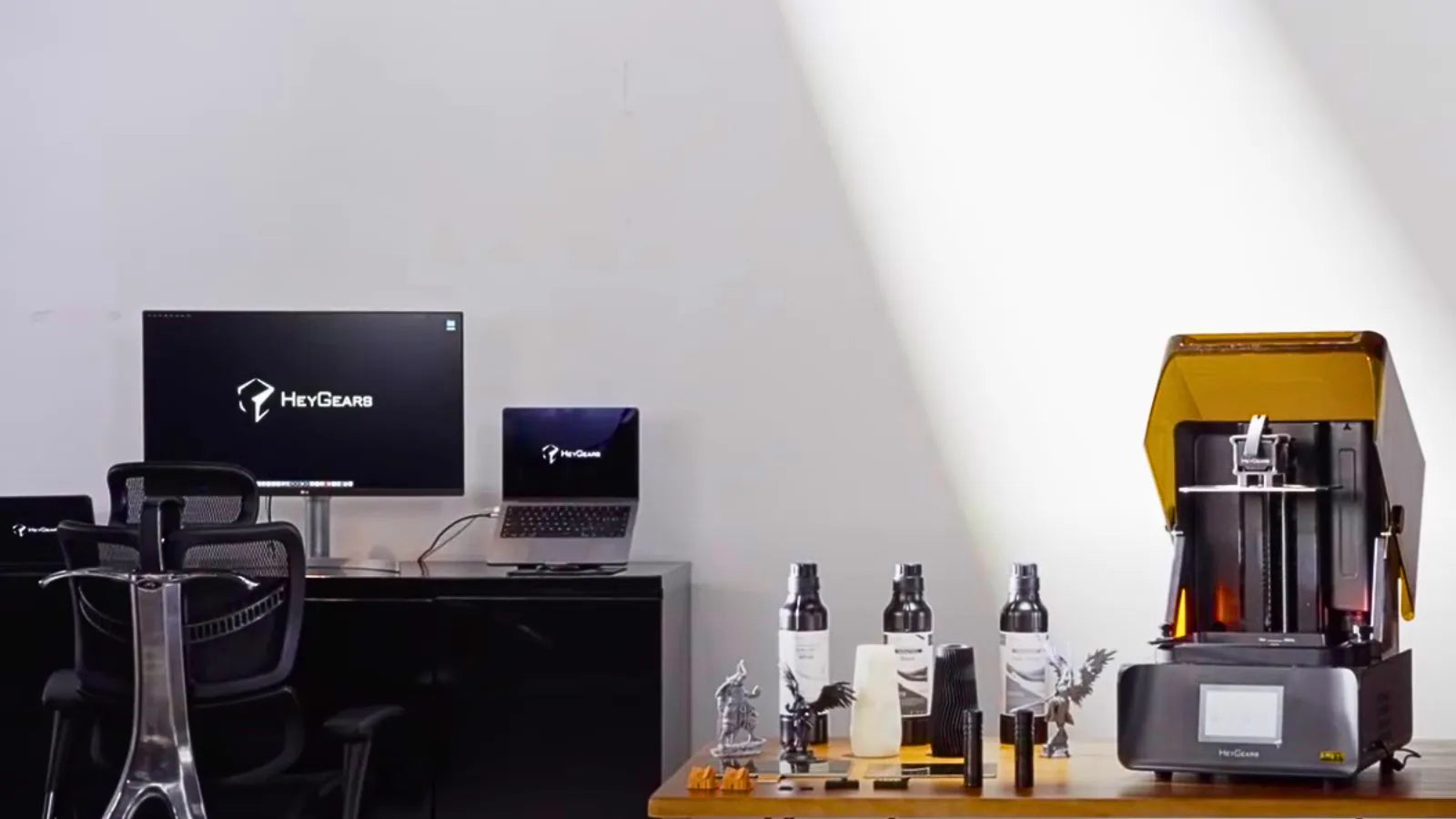

Printers in this category, such as the HeyGears Reflex RS 3D Printer, exemplify this market evolution by integrating professional-grade automation like force-monitoring sensors, auto-levelling, and intelligent software workflows into a platform that remains accessible to small businesses and serious creators.

Ideal for Small Businesses, Serious Hobbyists, and Prototyping

The capabilities of this tier cater to a more demanding user base:

-

Small Businesses and Entrepreneurs: Individuals running online stores, offering local 3D printing services, or using printers for small-batch manufacturing of end-use products find the reliability and throughput of these machines essential for commercial viability.

-

Serious Hobbyists: Creators who demand greater speed, larger print sizes for ambitious projects, and a significant reduction in the time spent on calibration and troubleshooting.

-

Engineers and Product Designers: Professionals who rely on an in-house machine for rapid prototyping, creating high-fidelity visual models, and performing fit tests before committing to the high costs of traditional manufacturing methods like injection moulding.

This prosumer tier is arguably the most dynamic segment of the market. Its growth is fueled by a powerful feedback loop: as entry-level users encounter the limitations of their machines in terms of size, speed, and manual upkeep, they create a strong demand for a more capable and reliable "next step". Concurrently, features once exclusive to high-end professional systems—such as heated vats and advanced motion controls—become more cost-effective to implement at a larger scale. Manufacturers capitalize on this by creating products that merge these advanced, reliability-focused features with the still-affordable MSLA technology. The result is a category defined not just by being bigger or faster, but by a fundamental shift in the user's relationship with the printer—it evolves from a tool requiring constant attention to a dependable appliance that consistently delivers high-quality results. This reliability is the critical enabler for any commercial activity, making this tier the true entry point for business use.

The Professional Grade: When Precision and Reliability are Paramount

At the apex of the resin 3D printing market lies the professional-grade tier. These are not merely machines but complete manufacturing solutions, where the primary considerations are return on investment, workflow integration, and the absolute assurance of repeatable, high-quality results. For industries where precision and reliability are non-negotiable, these systems represent a critical capital investment.

Price Range: The Investment for Industrial and Commercial Use

The financial commitment for professional-grade resin 3D printers begins around $3,000 and can extend well beyond $25,000, with some large-scale industrial systems reaching into the hundreds of thousands of dollars. This price reflects a shift in value proposition from the hardware itself to the comprehensive ecosystem and support that surrounds it.

Unlocking Top-Tier Features: Automation, Specialty Materials, and Support

Purchasing a professional-grade printer means investing in an entire production ecosystem. This typically includes the printer, a dedicated washing station, and a curing station, all designed, tested, and validated to work together seamlessly with proprietary software and materials.

Automation in this tier goes far beyond the quality-of-life features of mid-range machines. It encompasses sophisticated systems like automated resin handling via cartridges that mix and dispense materials, fleet management software to control and monitor entire print farms, and even integrations for robotic part removal in a 24/7 production environment.

A crucial differentiator is access to validated specialty materials. Professional systems offer a wide library of engineering-grade resins—including tough, heat-resistant, flexible, and biocompatible options—that have undergone rigorous testing to guarantee their mechanical properties. This validation is essential for industries like medical device manufacturing and dentistry, where parts must meet strict regulatory standards.

Finally, the higher cost includes unparalleled support and service. This can include on-site installation, comprehensive training for staff, and dedicated service plans that guarantee rapid response times. For any business, printer downtime translates directly to lost revenue, making professional, reliable support a critical component of the overall value.

Target Industries: Dentistry, Jewelry, Engineering, and Manufacturing

These high-end systems are tailored for specific, demanding industries:

-

Jewelry Manufacturing: Professional printers are used to produce master patterns for investment casting. They utilize specialized castable resins that are formulated to burn out completely during the casting process, leaving no ash residue, which is critical for creating flawless pieces in precious metals.

-

Engineering and Manufacturing: These systems are used to create functional prototypes that can withstand rigorous real-world testing, as well as jigs, fixtures, and other custom tooling for assembly lines. They are also employed for small- to medium-scale manufacturing of complex end-use parts where the cost of injection moulding would be prohibitive.

In this professional tier, the value proposition is fundamentally about the reduction of business risk. The customer is paying a premium to transfer the risks of process validation, material science, and technical troubleshooting to the manufacturer. Consequently, comparing a professional printer to a prosumer model on specifications like resolution alone misses the core value; the true product being sold is consistency, reliability, and regulatory compliance.

Factoring in the Total Cost of Resin Printing

The initial purchase price of a resin 3D printer is only the first line item in a much larger budget. To accurately assess the financial commitment, one must consider the total cost of ownership, which includes the recurring expenses of materials and the upfront cost of essential post-processing equipment and long-term maintenance.

The Ongoing Cost of Resins and Consumables

Photopolymer resin is the primary and most significant recurring cost associated with this technology. The price of resin varies dramatically depending on its specific properties and intended application. Prices can range from as low as $20 per kilogram for standard resins purchased in bulk to well over $1,000 per kilogram for highly specialized, medically-certified biocompatible materials. The choice of material is directly linked to the project's requirements, and this choice will be a major driver of the overall operational cost.

The following table provides a general overview of resin costs by type:

|

Resin Type |

Typical Price Range (USD per 1kg/1L) |

Primary Use Cases & Characteristics |

|

Standard Resin |

$20 - $70 |

General prototyping, miniatures, and visual models. Good detail, but can be brittle. |

|

$25 - $80 |

Similar to standard resin but cleans with water, avoiding the need for IPA. |

|

|

ABS-Like Resin |

$40 - $200+ |

Functional parts, mechanical prototypes, enclosures. Improved impact resistance and durability. |

|

Flexible Resin |

$60 - $250 |

Gaskets, seals, wearables, shock absorbers. Simulates properties of rubber or TPU. |

|

Castable Resin |

$75 - $300+ |

Jewelry and dental patterns for investment casting. Designed to burn out cleanly with no ash. |

|

Biocompatible Resin |

$150 - $1,000+ |

Medical and dental applications, like surgical guides and hearing aids. Certified for skin or mucosal contact. |

Essential Post-Processing Equipment: Washing and Curing Stations

Unlike FDM printing, post-processing in resin printing is a mandatory part of the workflow. When a print is finished, it emerges from the printer in a "green" state—tacky to the touch and not fully cured. It must first be washed to remove all residual liquid resin from its surface and then post-cured with UV light to achieve its final strength and stability.

Dedicated wash and cure stations are highly recommended for this process. These units, which often combine both functions into a single device or a matched pair, typically cost between $100 and $400, depending on their size and features. In addition to the hardware, the cleaning agent itself is a recurring cost. Isopropyl alcohol (IPA) is the most common solvent, generally costing $20 to $40 per gallon.

Maintenance, Software, and Long-Term Expenses

Over the life of the printer, several components will require replacement, and other costs will accumulate. These "hidden" expenses are a critical part of the TCO calculation.

The most common consumable parts are the FEP or ACF film at the bottom of the resin vat. This transparent film becomes cloudy with use and can be accidentally punctured, requiring periodic replacement. Fortunately, this is a relatively minor expense, with multi-packs typically costing between $20 and $50.

A more significant long-term cost is the LCD screen. Modern monochrome screens have a finite lifespan, generally rated for 2,000 to 3,000 hours of use. Eventual replacement is inevitable. Depending on the printer's size and resolution, a new screen can cost anywhere from $100 to over $350.

Regarding software, most consumer and prosumer printers are compatible with excellent free slicer programs. However, for professional and commercial applications, the cost of advanced Computer-Aided Design (CAD) software and specialized manufacturing suites can be substantial, with licenses ranging from around $50 per year for maker editions to several thousand dollars per year for professional packages.

Finally, ancillary costs for items like nitrile gloves, paper towels, funnels with filters for saving unused resin, and proper hazardous waste disposal should be factored in, as these small expenses add up over time.

A crucial consideration when evaluating the total cost is the interplay between initial price and long-term operational expense. An entry-level machine, while cheap to acquire, may have a higher rate of print failures due to its manual calibration and less robust design. Each failed print represents a direct loss in wasted resin and, for a business, a significant opportunity cost in lost time. A more expensive prosumer model with automated features that drastically reduce failures could, over a year of operation, prove to be more economical by saving on materials and maximizing productive uptime. This demonstrates that the "cheapest" printer to buy is not always the most cost-effective printer to own and operate.

Related articles:

Essential 3D Printing Tools Guide: From Basics to Advanced, Mastering Key Tools

Cura Ironing Explained: How to Get Smoother Top Layers in 3D Printing

Websites for Free 3D Printing STL Files

Share:

How Does Resin 3D Printing Work? A Comprehensive Guide to Vat Photopolymerization

The Architect's Choice: Best Resin 3D Printers for Stunning Architectural Models