Additive manufacturing, more commonly known as 3D printing, has fundamentally reshaped the landscape of design, prototyping, and production. The technology, first developed in the 1980s, operates on a simple yet revolutionary principle: building three-dimensional objects from a digital file by adding material one layer at a time. This "additive" approach stands in stark contrast to traditional manufacturing methods. Subtractive processes, like CNC milling, carve objects from a solid block of material, while formative methods, such as injection moulding, reshape a material into a desired form. By constructing parts layer by layer, 3D printing unlocks the ability to create geometrically complex designs that would be impossible or prohibitively expensive to produce otherwise.

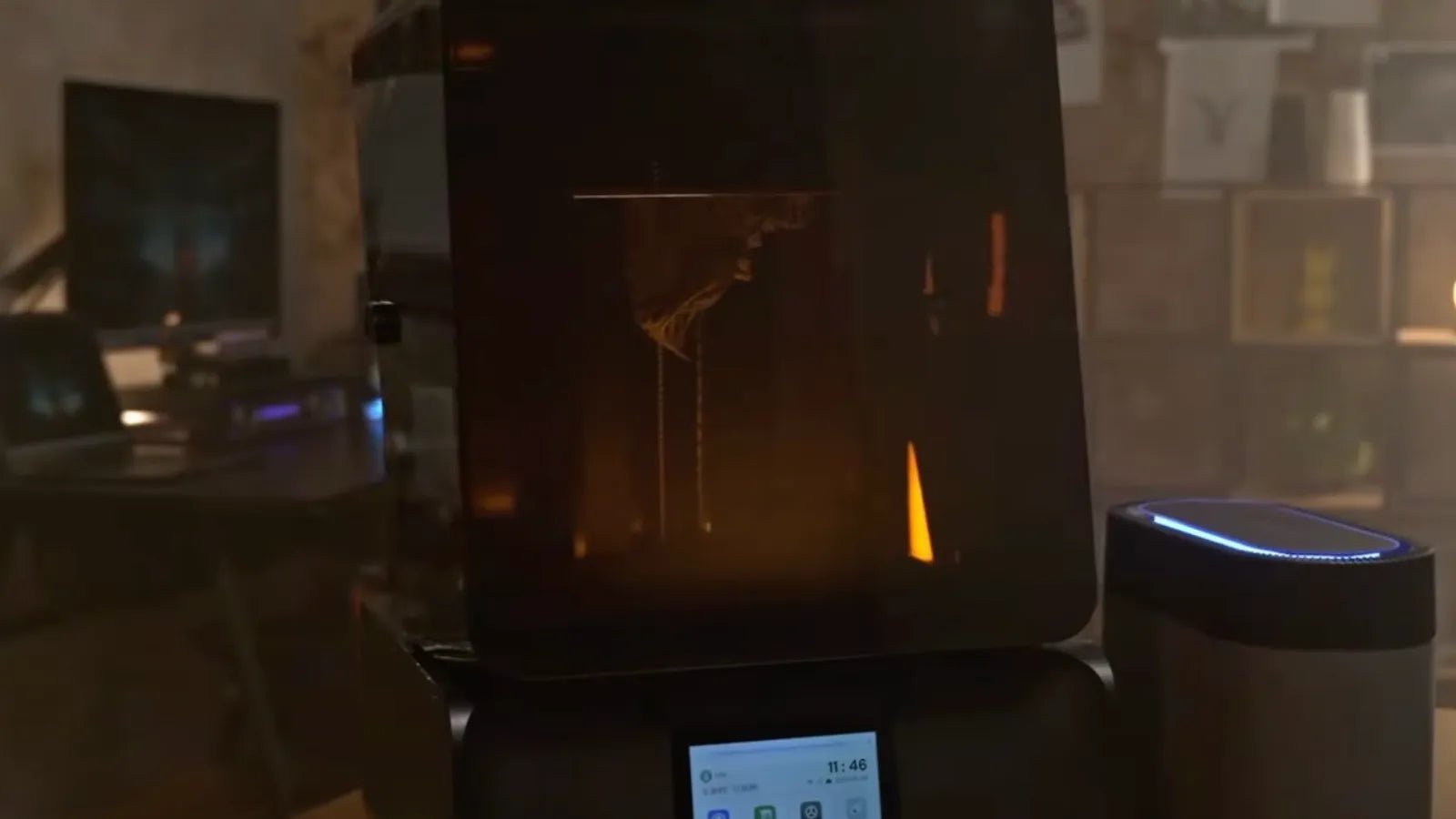

Within the diverse family of 3D printing technologies, one category stands out for its exceptional precision and surface quality: resin 3D printing. This advanced method has become the gold standard for applications where fine detail is not just a preference, but a requirement.

Answering the Core Question: So, What is 3D Printing with Resin?

At its core, resin 3D printing is an additive manufacturing process that uses a liquid, light-sensitive material—a photopolymer resin—and a controlled light source to build an object. Instead of melting plastic filament or fusing powder, a resin printer selectively exposes a vat of liquid resin to ultraviolet (UV) light. Where the light strikes the resin, it triggers a chemical reaction that instantly solidifies, or cures, the liquid into a hard plastic layer. The printer's build platform then moves by a minuscule amount, and the process repeats, building the object one infinitesimally thin layer upon the next until the final, highly detailed part is complete.

The Fundamental Principle: Vat Photopolymerization Explained

The scientific term for the process behind resin 3D printing is vat photopolymerization. This name perfectly describes the core mechanics: a vat holds the liquid photopolymer, and light is used to create a solid object through polymerization.

The process begins with a 3D digital model, which is fed into specialized software called a "slicer." The slicer converts the model into hundreds or thousands of thin horizontal cross-sections, creating a precise, layer-by-layer blueprint for the printer. The printer then executes these instructions meticulously. For each layer, a light source projects a pattern corresponding to that cross-section onto the resin. The UV energy from the light initiates a chemical reaction called photopolymerization, causing short molecular chains within the liquid resin (monomers and oligomers) to rapidly link together and form a solid polymer network. This creates a thermoset plastic, a material that is strong, stable, and cannot be remelted once cured. This fundamental reliance on a chemical phase change (liquid to solid) rather than a thermal one (melting and cooling) is the primary reason for resin printing's superior detail and smooth finish compared to other methods.

The Key Ingredients: Liquid Resin, a UV Light Source, and a Build Platform

Every vat photopolymerization system, regardless of its specific type, relies on three essential components working in concert:

-

Liquid Photopolymer Resin: This is the raw material of the process. It is a specially formulated liquid mixture containing the building blocks (monomers and oligomers) and photoinitiators, which are compounds that kickstart the curing reaction when exposed to UV light. Additives like pigments and fillers are also included to give the final part specific colours or mechanical properties.

-

A UV Light Source: This is the catalyst that transforms the liquid into a solid. The nature of this light source is the main differentiator between the various types of resin printing technologies. It can be a highly focused laser, a digital projector, or a powerful array of LEDs.

-

A Build Platform: This is the surface on which the object is constructed. It moves with extreme precision—often by fractions of a millimetre—after each layer is cured, allowing a fresh film of liquid resin to flow into place for the next layer to be formed.

The Different Types of Resin 3D Printing Technology

While all resin printers operate on the principle of vat photopolymerization, the method used to deliver light to the resin defines three distinct technologies: Stereolithography (SLA), Digital Light Processing (DLP), and Masked Stereolithography (MSLA).

SLA (Stereolithography): The Original Laser-Based Method

Stereolithography was the very first 3D printing technology to be commercialized, patented in 1986 by its inventor, Chuck Hull. An SLA printer uses a high-precision ultraviolet laser to cure the resin. This laser is directed by a pair of computer-controlled mirrors, known as galvanometers, which trace the exact path of each layer's cross-section onto the surface of the liquid resin, curing it point by point.

This method is analogous to drawing a picture with an exceptionally fine-tipped pen. Because the laser beam can be focused to a very small spot size, SLA is renowned for its ability to produce parts with outstanding accuracy, intricate details, and the smoothest surface finishes available in 3D printing. However, this meticulous point-by-point process means that SLA can be slower than other resin technologies, particularly when printing large, solid parts or a full platform of multiple objects.

DLP (Digital Light Processing): Using a Digital Projector

Digital Light Processing offers a significant evolution in speed. Instead of a laser tracing each layer, a DLP printer uses a digital projector to flash an image of the entire layer onto the resin vat all at once. This is comparable to using a stamp to create an entire image in a single motion.

The image is generated by a component called a Digital Micromirror Device (DMD), a semiconductor chip covered in millions of microscopic mirrors. Each tiny mirror corresponds to a pixel in the projected image and can be individually controlled to direct light toward the resin or away from it. Because an entire layer is cured in a single flash lasting just a few seconds, DLP technology is significantly faster than SLA, especially for large or numerous parts. The resolution of a DLP print is determined by the projector's pixel density; the 2D image is composed of square pixels, which form three-dimensional rectangular blocks called voxels.

MSLA (Masked Stereolithography): The Widespread LCD-Based Approach

Masked Stereolithography, often referred to simply as LCD 3D printing, functions similarly to DLP by curing an entire layer at once, but it uses a different mechanism. An MSLA printer employs a powerful array of UV LEDs as its light source. Positioned between the LEDs and the resin vat is a liquid-crystal display (LCD) screen that acts as a mask.

For each layer, the LCD displays a negative image of the cross-section: the pixels corresponding to the part's shape become transparent, allowing the UV light to pass through and cure the resin, while the rest of the screen remains opaque. The use of mass-produced, high-resolution LCD screens and simple LED arrays has made MSLA technology incredibly cost-effective, driving the explosion of affordable and high-quality desktop resin printers for consumers and professionals alike. Its speed is comparable to DLP, and its resolution is dictated by the pixel density of the LCD screen.

Why Choose Resin? The Key Advantages and Applications

The decision to use resin 3D printing stems from its unique ability to deliver results that other technologies cannot match. Its advantages in detail, surface quality, and material versatility have made it an indispensable tool across a wide range of industries.

Unmatched Detail and Smooth Surface Finishes

The most significant advantage of resin 3D printing is its superior print quality. The technology consistently produces parts with exceptionally fine details, sharp edges, and surfaces so smooth they often show no visible layer lines. This high fidelity is a direct result of the photopolymerization process, which allows for layer heights as low as 25 microns (0.025 mm) and features defined by the microscopic resolution of a laser or pixel. Furthermore, the chemical bonds that form between layers create parts that are isotropic, meaning they exhibit consistent mechanical strength in all directions, making them reliable for functional applications.

Common Uses: From Jewelry to Miniature Figurines

The precision of resin printing has made it a transformative force in several key fields:

-

Jewelry: Jewellers use resin printers to create master patterns for investment casting. Using specialized "castable" resins that burn away cleanly without leaving ash, they can produce intricate and complex designs that would be incredibly difficult or time-consuming to carve from wax by hand. This allows for rapid prototyping of custom pieces and efficient production of multiple patterns at once.

-

Miniature Figurines and Models: For hobbyists and professionals in the tabletop gaming and collectibles industries, resin printing is the technology of choice. It can capture the minuscule details of a character's face, the texture of armour, or the delicate features of a scale model with a level of fidelity that other desktop printing methods cannot achieve. The smooth finish also provides an ideal canvas for painting.

Material Variety: Exploring Different Types of Photopolymer Resins

The versatility of resin printing is greatly enhanced by the ever-expanding library of available materials. While early printers were limited to basic resins, today's market offers a vast selection of photopolymers engineered for specific functional outcomes:

-

Standard Resins: Ideal for general-purpose prototyping and visual models where high detail is the primary concern.

-

Tough and ABS-like Resins: Formulated to withstand mechanical stress, these materials are perfect for creating durable functional prototypes, jigs, fixtures, and enclosures.

-

Flexible and Elastic Resins: These materials mimic the properties of rubber or silicone, making them suitable for parts that need to bend, flex, and compress, such as gaskets, grips, and wearables.

-

Castable Resins: Designed specifically for investment casting, these resins burn out cleanly, a critical property for jewelry-making applications.

This diversification in material science is what has allowed resin printing to evolve from a prototyping tool into a viable solution for producing specialized, end-use parts.

Conclusion: Understanding What Resin 3D Printing Offers Your Projects

Resin 3D printing, powered by the science of vat photopolymerization, represents the pinnacle of precision and detail in the world of additive manufacturing. By transforming liquid resin into solid objects with meticulously controlled light, technologies like SLA, DLP, and MSLA offer a powerful tool for anyone who needs to translate complex digital designs into high-fidelity physical parts.

Its value proposition is clear: for applications where intricate details, smooth surfaces, and material-specific properties are critical—from custom jewelry to hyper-realistic miniatures and functional prototypes—resin 3D printing provides capabilities that are simply unmatched. While the process requires careful handling and post-processing, the extraordinary quality of the final result makes it an indispensable technology. From hobbyist workshops to advanced digital manufacturing solutions provided by innovators like HeyGears, resin 3D printing is empowering creators to bring their most detailed visions to life with stunning clarity and precision.

Related articles:

How to Convert OBJ Files to STL: Complete Guide

Different Types of 3D Printer Consumables: Resin vs FDM

PLA vs. PLA+: A Complete Guide to 3D Printing

Share:

Resin 3D Printing: Achieving Smooth Surfaces and Intricate Details

HeyGears Resin 3D Printer Design Concepts and Inspirations