Purchasing a 3D printer often feels confusing, as there is a range of printers available today. You wonder how much is a 3D printer and search, only to find some machines for a few 100 dollars, while others cost tens of thousands of dollars.

This price gap makes many buyers unsure what they actually need. This article covers 3D printer prices from entry-level to professional, explains hidden costs, and gives buying tips to help you choose with confidence.

A Brief 2026 3D Printer Comparison Cost Table

The table below outlines the price ranges from entry-level to industrial 3D printers.

|

Printer Type |

Typical Price Range |

Brief Description |

|

Entry-Level |

$200–$800 |

These are basic machines for beginners, learning, and light prototyping |

|

Mid-Range |

$800–$2,000 |

These offer better accuracy, reliability, and material support |

|

Prosumer |

$2,000–$5,000 |

Advanced features for serious users and small businesses |

|

Professional/ Industrial |

$5,000+ |

High precision, automation, and production-grade reliability |

Entry-Level 3D Printers ($200–$800)

Starter-level 3D printers are designed to target amateurs and novices. These printers tend to provide less sophisticated motion systems, minimal automation options, and smaller volumes of build. They are suitable for the acquisition of basics and printing uncomplicated parts.

Mid-Range 3D Printers ($800-$2,000)

Mid-range printers provide a significant increase in reliability alongside printing quality. These printing machines normally have finer movement parts, better electronics, and frame stability. Most of them also accommodate a wide variety of materials.

Moreover, mid-range 3D printers offer great value to users who have to print relatively small production volumes or functional/testing prototypes. You will have more consistency without having to shift to full industrial pricing.

Prosumer 3D Printers ($2,000-$5,000)

These machines are concerned with repeatability, automation, and efficiency of workflow. Such characteristics as closed chambers, advanced sensors, and software integration become standard. The type fits small companies, engineering teams, and design firms. The increased cost is an expression of less downtime and better quality of printed items.

Professional and Industrial 3D Printers ($5,000+)

Industrial and professional printers are built for mass-scale production use. These machines are highly accurate, reliable, and automated. But these features add a high cost. They tend to endorse engineering materials like ABS, nylon, polycarbonate, and carbon-fiber composites, and maintain tight tolerances.

Industrial printers save on labor cost by automation and need minimum operator involvement. Investment in the high initial expense is paid back through the performance over time and consistent output.

What Factors Influence the Price of 3D Printers?

Several key factors determine the cost of a 3D printer. These affect both its capabilities and overall value.

Printing Technology

Different printing technologies vary widely in price. FDM 3D printers are less expensive, whereas resin, SLS, and industrial printers are more costly. Both technologies have an impact on the accuracy, surface finish, and material behavior. State-of-the-art or advanced technologies demand superior quality parts and sophisticated control. This directly adds the costs of manufacture and purchase.

Build Volume and Print Size

Frames and motion systems are required to be more robust when the build volume is large. This is technically challenging to do when covering a wide area. This cost increases with the size of the printer. Smaller printers are less expensive but constrained in part size. The bigger printers are appropriate when it comes to production, but are pricier at their start.

Print Quality, Accuracy, and Speed

Precision printing involves the employment of stiff frames and motion components. An increase in the printing speed also demands improved motors and control mechanisms. These features have a significant effect on price. The cheaper printers are usually less accurate or quicker, while the professional machines are always balanced.

Materials Compatibility

3D Printers that are compatible with engineering-grade materials are generally more expensive. High-temperature materials require heated chambers and hardened components. This makes these systems more complicated. Entry-level Printers normally only support standard plastics. Professional/industrial printers work with highly-developed materials in a stable way.

Build Quality

Frame materials, electronics, and mechanical components influence the life span of the printer. Metal frames and industrial-grade components are more durable. These improvements increase the cost of purchase but lower the maintenance. In addition, the build quality has a direct impact on the ownership expenses in the long run.

Software and Automation

Advanced or innovative software will be of great value. All these properties, such as automatic calibration, monitoring, and workflow controls, are time-saving. These systems lower the downtime and errors by operators. Professional printers cost a lot to automate.

Buying Recommendations for Different Price Ranges

Choosing the right 3D printer often depends on your budget and your needs. Here are different levels of 3D printers for your consideration.

Best Entry-Level 3D Printers Under $800

The entry-level consumers are supposed to pay attention to reliability and functionality. An entry-level printer reduces frustration during setup and barriers to learning. The Ultra Craft Reflex RS 3D Printer is an entry-level printer. It is reliable and predictable in the performance and results of new users, and costs are typically lower than $800.

Its setup process is quick and straightforward. You can have it ready to print in just minutes, and slicing models for printing can be done with a one‑click workflow, which removes a lot of the complexity that often discourages beginners. Several automated features further ease the learning curve.

Best Mid-Range 3D Printers Around $1,000-$1,500

Mid-range buyers usually prefer better material consistency and greater flexibility. It is an ideal category for those who print out functional prototypes or limited quantities. The Reflex RS Turbo enhances the accuracy, speed, and efficiency of work. It suits users who go beyond the hobby printing scope.

The floating screen auto-leveling and automatic resin refill systems continue to simplify setup and reduce manual calibration, saving you time as you focus on more complex projects. Its robust C5-grade Z-axis module, combined with Dynamic Motion Algorithm 3.0, ensures precision and faster print speeds.

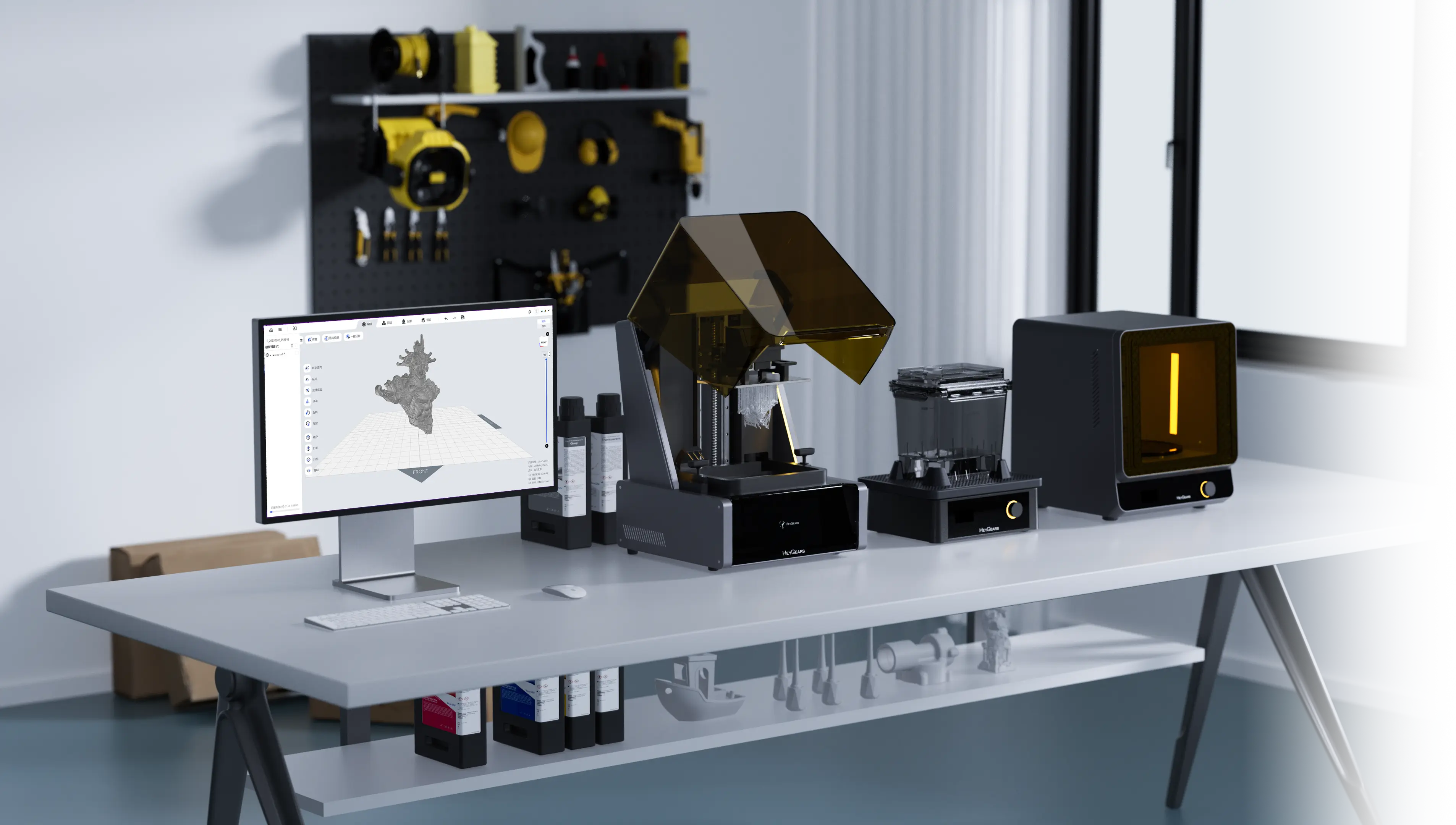

Best Professional 3D Printers $2,000+

Business clients are concerned with repeatability and availability. Therefore, printers must be capable of producing uniform products with limited oversight. The Reflex 2 Pro 3D Printer is designed to fit into professional processes and high-performance uses. It assists in stable production quality printing.

It features a large build volume that’s more than 2× larger than many entry‑level machines. This lets you produce bigger parts or multiple components in a single run, a key advantage for businesses and advanced users.

At the heart of its performance is an advanced OptiZone Light Engine with 1,032 individually controlled zones, which enables highly uniform and precise light projection across the entire print area. This dramatically improves surface quality, dimensional accuracy (≤ ± 0.05 mm), and curing consistency.

What Hidden Costs Should You Expect After Buying a 3D Printer?

Beyond the initial purchase, several hidden costs can add up when owning and operating a 3D printer.

Material and Consumables

Printing materials represent ongoing costs. Filament, resin, and support materials add up over time. Higher-performance materials cost significantly more. Besides this, material waste during the printing process also affects expenses.

Maintenance and Upkeep

All 3D printers requires maintenance. Nozzles, build plates, and filters require replacement after some use. Regular cleaning and calibration are necessary. However, professional machines reduce maintenance frequency but still require upkeep.

Electricity and Upgrades

3D printers consume electricity during long print jobs. Heated beds and chambers increase power usage. Firmware and hardware upgrades also add up costs. If you want a clearer estimate of typical power usage and the electricity cost per print, see How Much Electricity Does a 3D Printer Use.

Potential Repairs

Mechanical and electronic failures happen over time. So, printer motors, sensors, and control boards may need replacement. Warranty coverage varies by manufacturers and higher-quality printers usually fail less often.

FAQ

How Much Does 3D Printing Plastic Cost?

3D printing filament typically costs less than resin per kilogram. Engineering plastics are more expensive than standard materials.

How Much Does It Cost to 3D Print One Part on Average?

Part cost depends on material, time, and energy usage. Simple parts cost only a few dollars. On the other hand, larger or complex parts cost significantly more.

Is It Cheaper to Buy a 3D Printer or Outsource 3D Printing Services?

Buying is cheaper for frequent printing. Outsourcing works better for occasional or specialized parts. So, it depends on your usage volume to determine cost efficiency.

Is 3D Printing a Cheap Hobby for Beginners?

3D printing can be affordable at the entry level. Costs rise with printer upgrades and materials, so beginners should budget for learning expenses.

Which Is More Expensive: 3D Printing or Laser Cutting?

Laser cutting equipment is usually more expensive initially. Operating costs vary by material and application; however, each serves different manufacturing needs.

Conclusion

Now you know the answer to how much is a 3D printer costs varies a lot, based on capability, reliability, and intended application. Entry-level machines are suited to students for learning basic printing, while professional systems support production. Understanding price drivers prevents costly mistakes. Beyond purchase price, materials and maintenance affect ownership cost. Choosing the right category means long-term satisfaction and value. With clear expectations, you can invest in a 3D printer that fits your budget and workflow.

共有:

Do You Need to Vent ABS When 3D Printing?

What Causes Stringiness on 3D Prints?