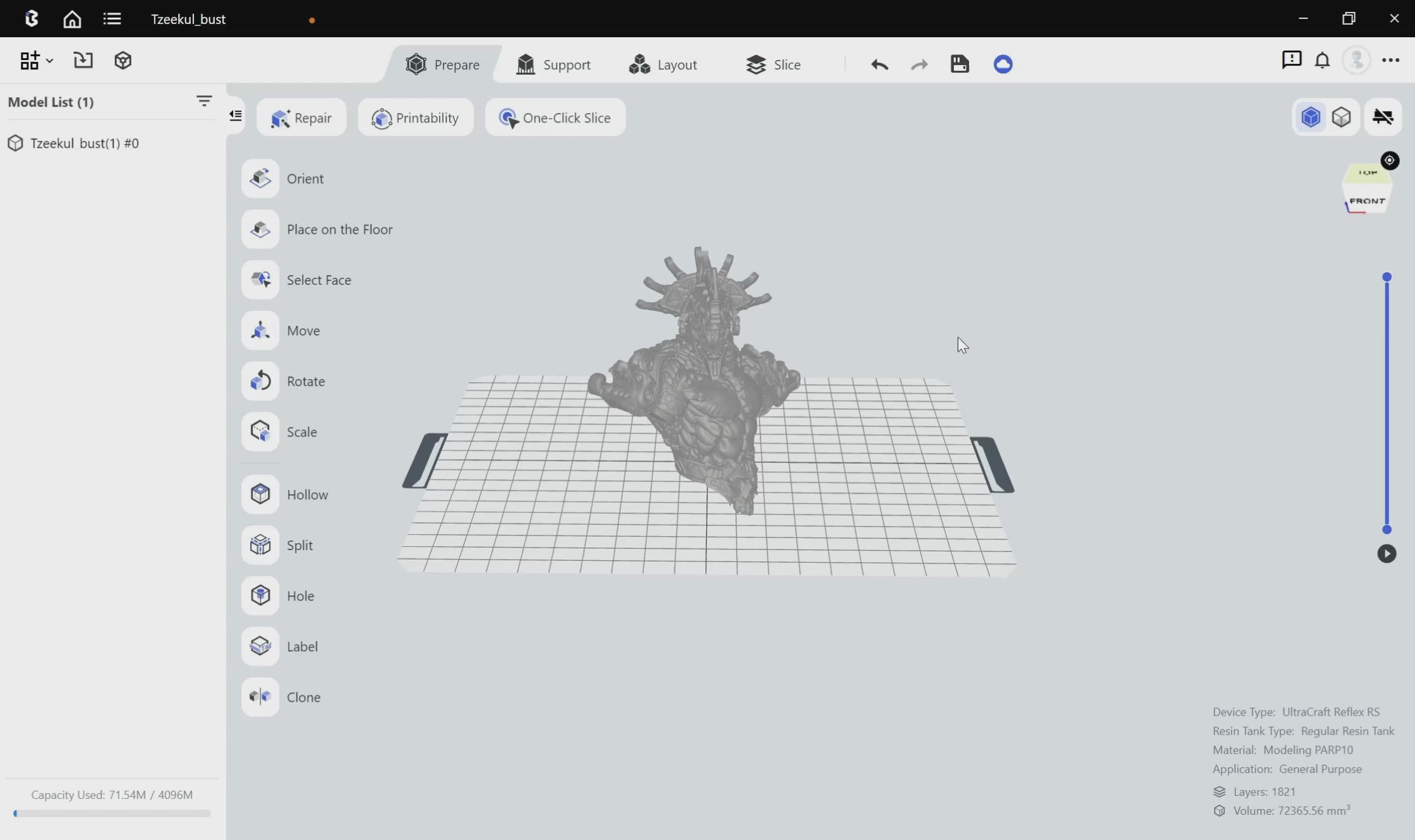

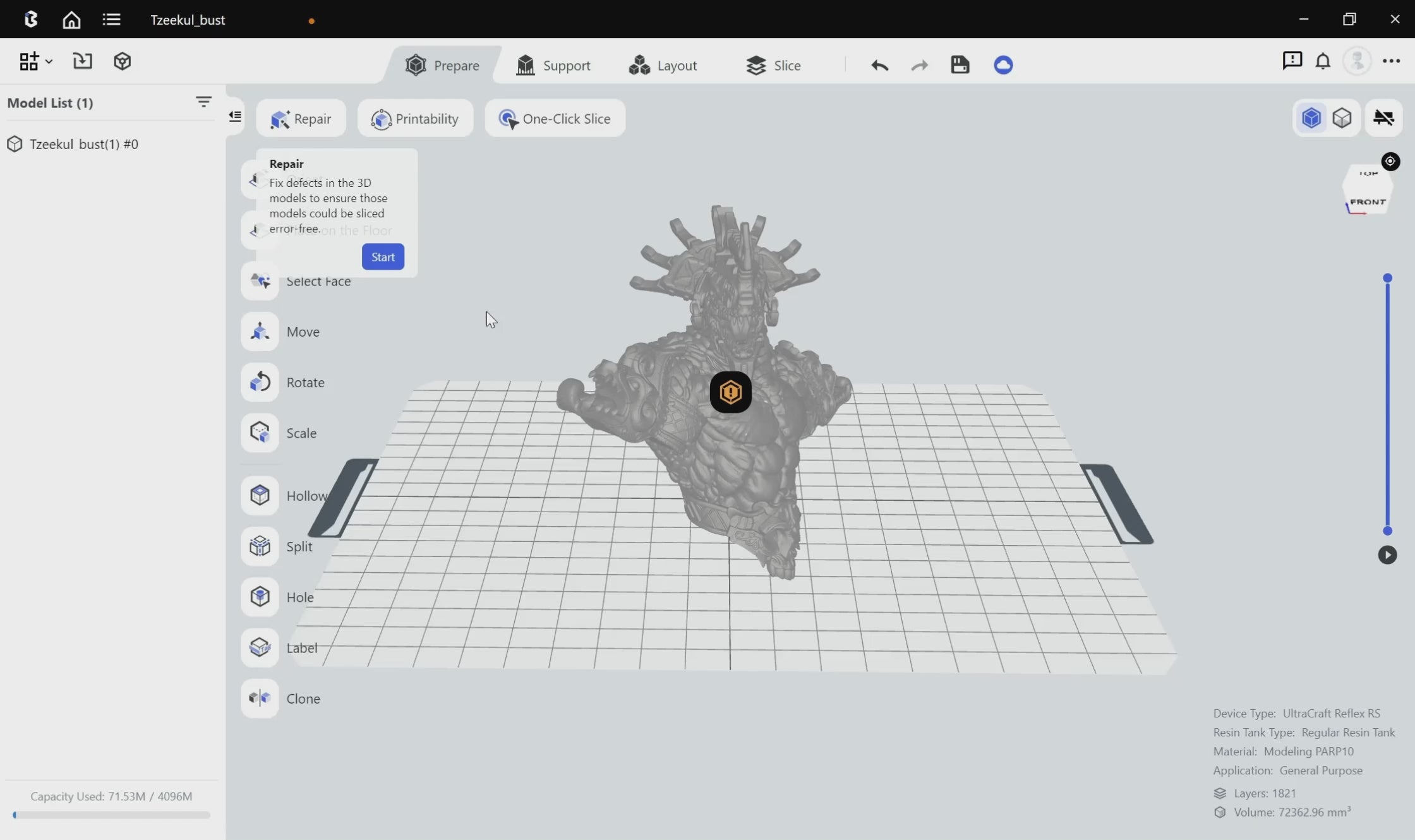

Experience fully integrated workflows—from printing to washing to curing—without the need for additional parameter adjustments.

Extra $50 Off Code: HG50NEW

New to HeyGears? Get $50 Off 3D Printers – Use Code: HG50NEW

(New users only. Code valid for 3D printers.)

Try PAH10 – Just Released

PAH10 Black is a high-stiffness,high-precision resin. It features a tensile modulus of 3150 MPa, offering exceptional long-term deformation resistance. It is ideal for load-bearing structural designs, silicone mold tooling, component housings, accessories and fittings.

Resin Highlights

- Exceptional Deformation Resistance

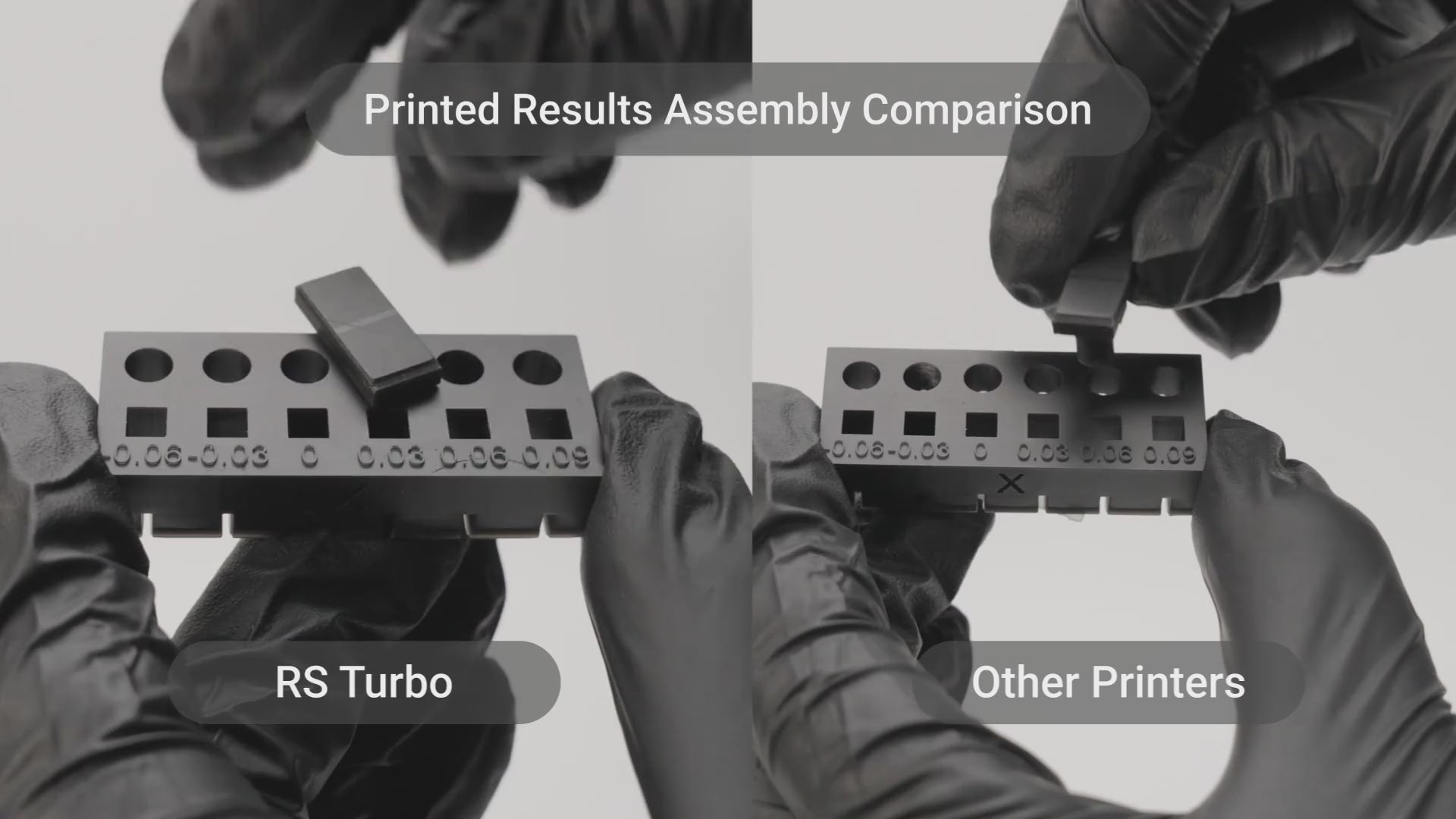

- ±0.05 mm Printed Part Tolerance for Precise Assembly

- 0.14 mm Thin-Walled Printability

- Heat-resistant up to 95 °C / 203 °F

- Long-Term Dimensional Stability

- Save More, Achieve More — 57% Lower Cost Than Comparable

RS Turbo Resin Compatibility & Recommendations

RS Turbo Compatible Resins:

PAS10, PAF10, PAP10, PARP10, PAWR10, PAU11, PAWW10, PAWW20.

🛒 You can [click here] to browse all resins for RS Turbo printers.If you're not sure which resin to choose, here are our top picks for the RS Turbo:

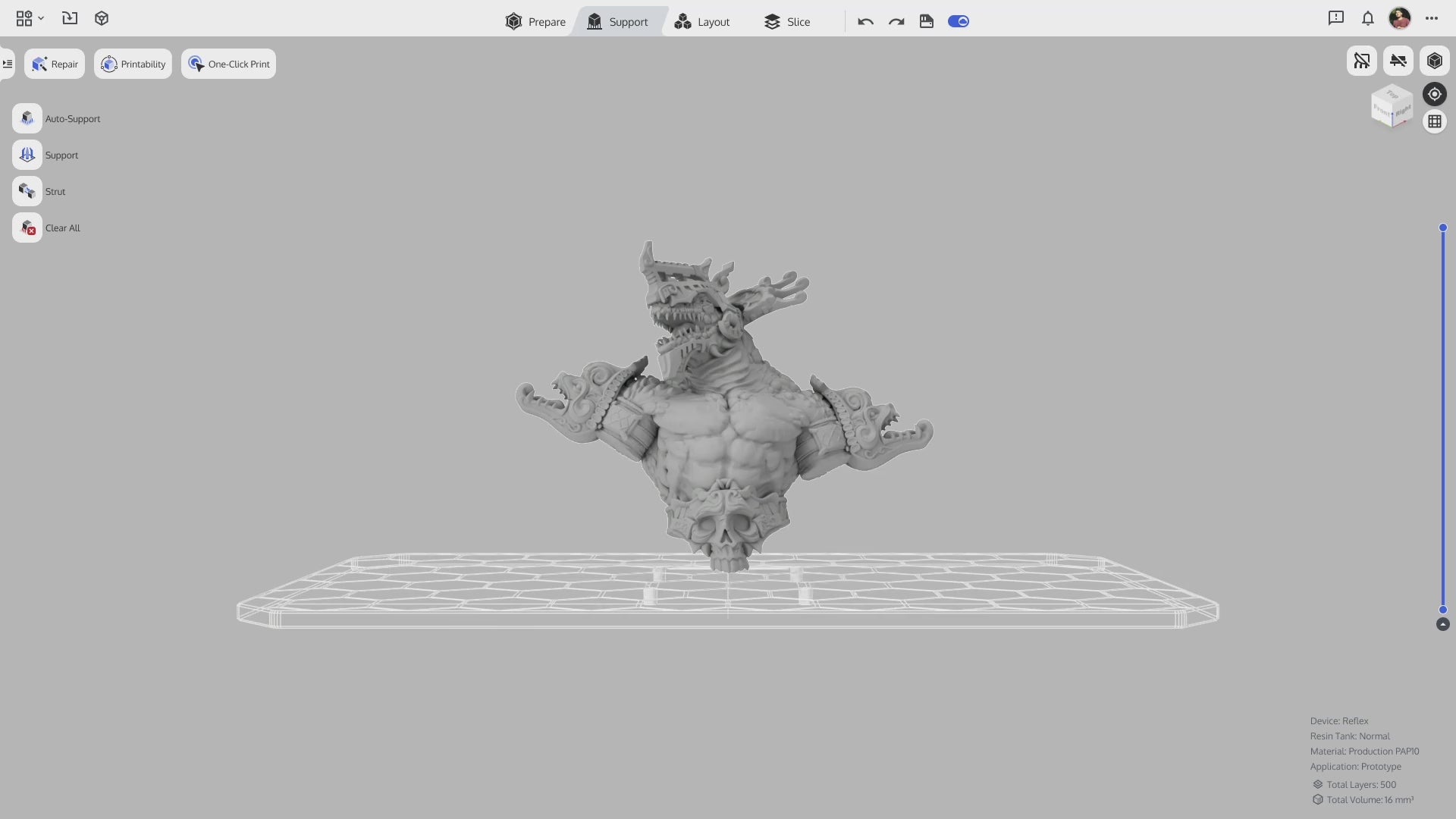

- PAS10 (Black, White, Purple): Best value for everyday use. Great for aesthetic prototypes, miniatures, and figurines.

- PAF10: Flexible resin that handles fine details well. Excellent for gaming minis, figurine accessories, and flexible prototypes.

- PAP10 (Gray, Black): Pro choice for models with intricate structures and fine details. Ideal for detailed tabletop miniatures and models with textured surfaces.

- 🔍 If you're a miniature enthusiast, check out [this page] for more resin suggestions.

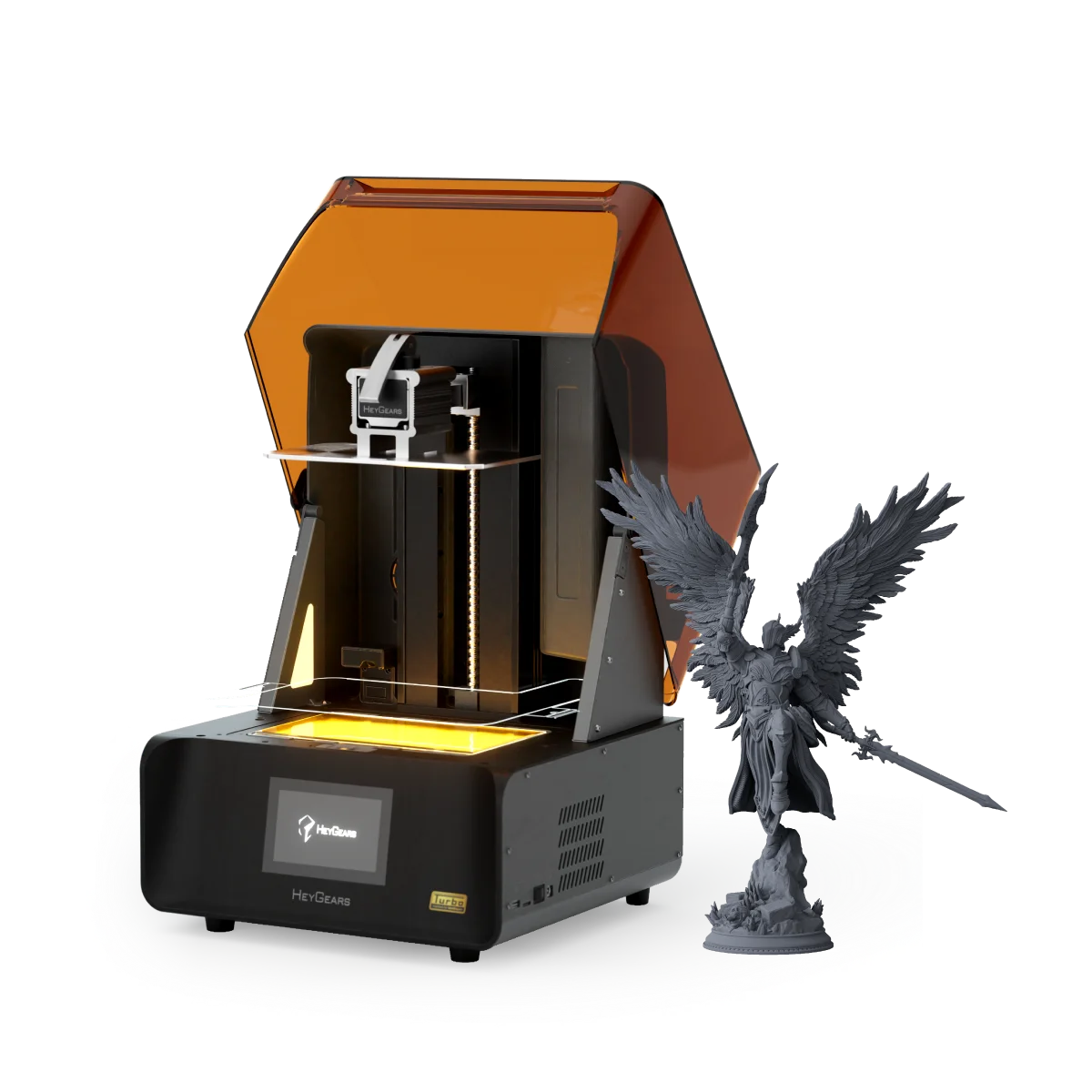

Product Highlights

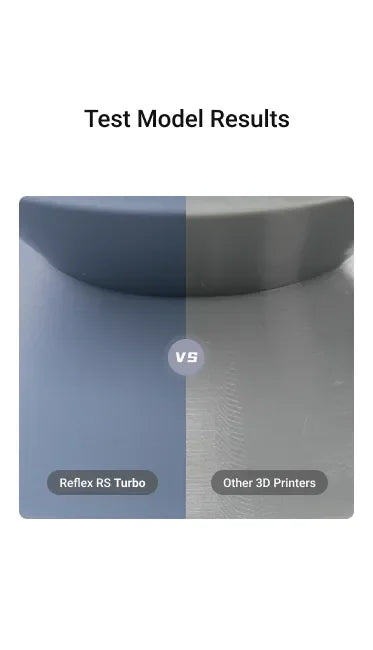

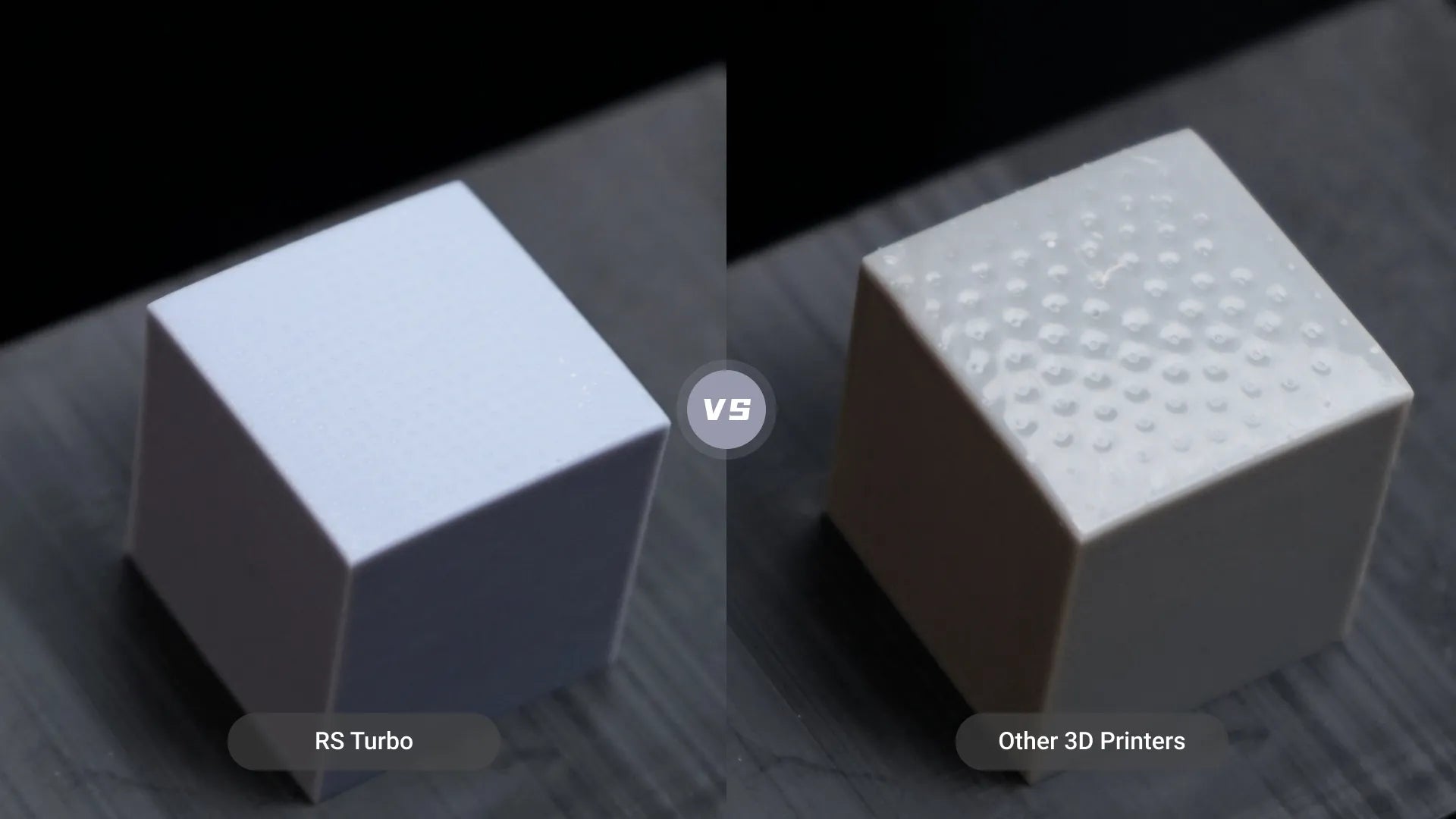

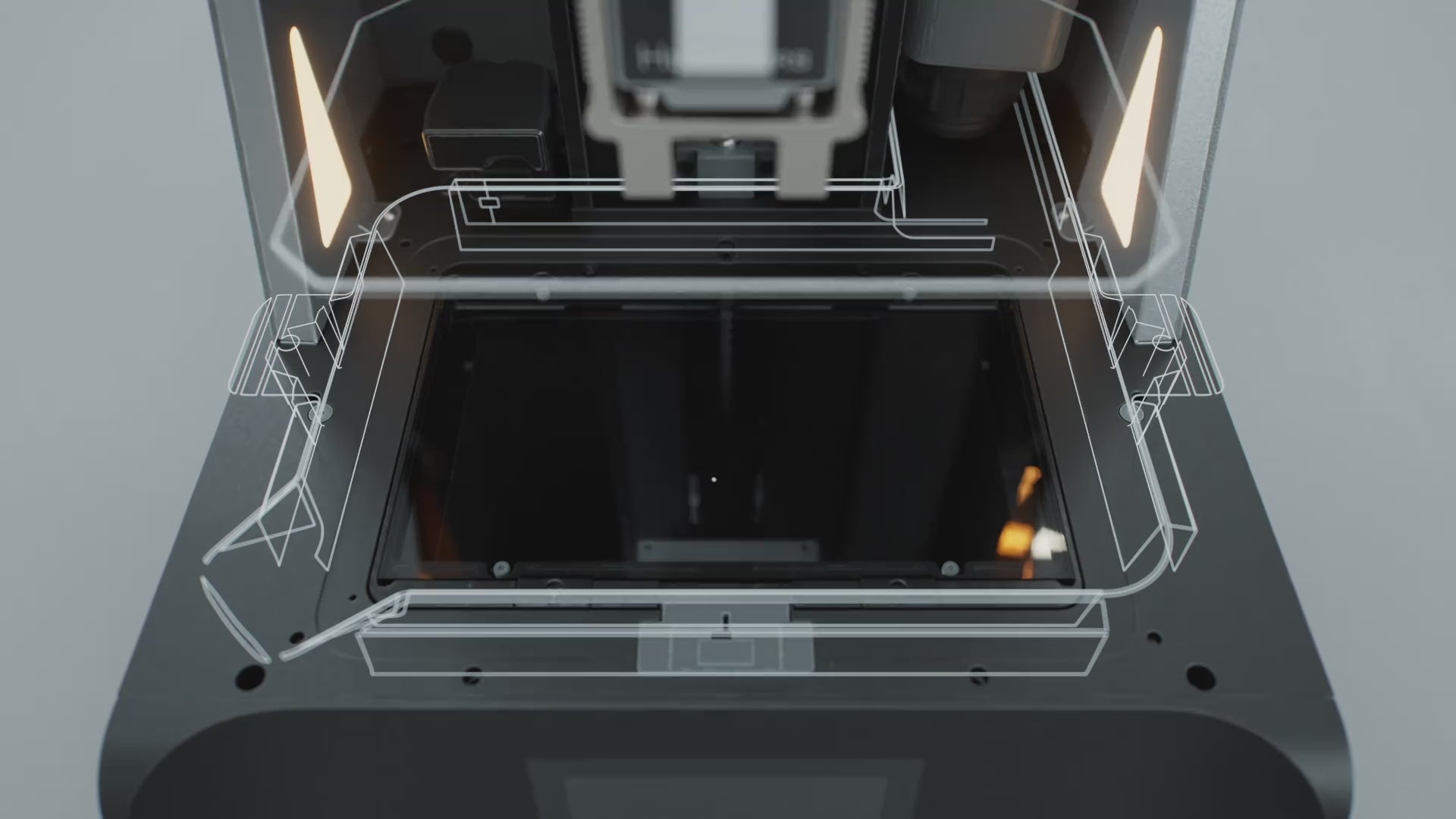

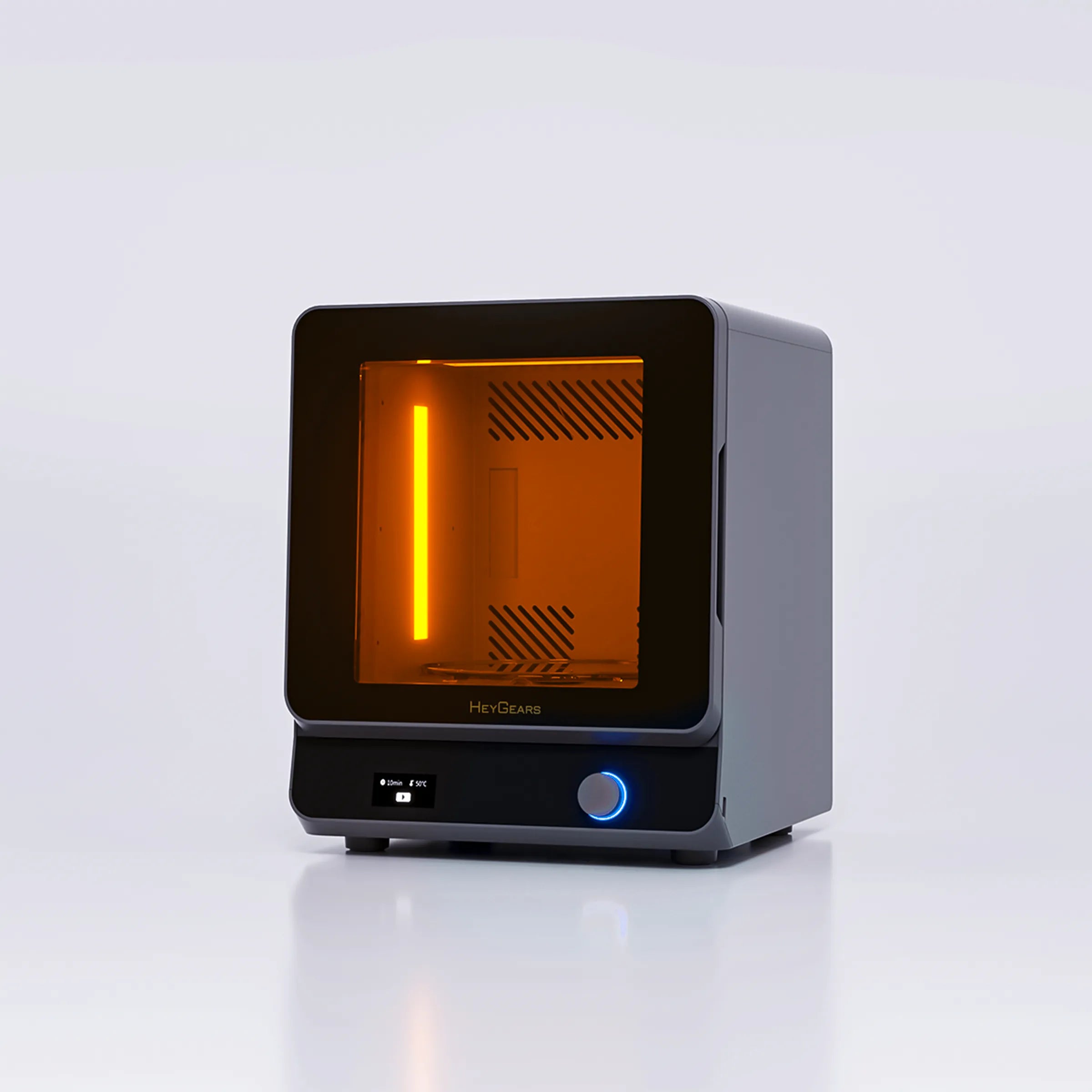

RS Turbo with Upgraded Amber Screen:

- Excellent Sharpness & Enhanced Surface Quality with Fast Printing Speed.

- Over 1 million printed layers capability.

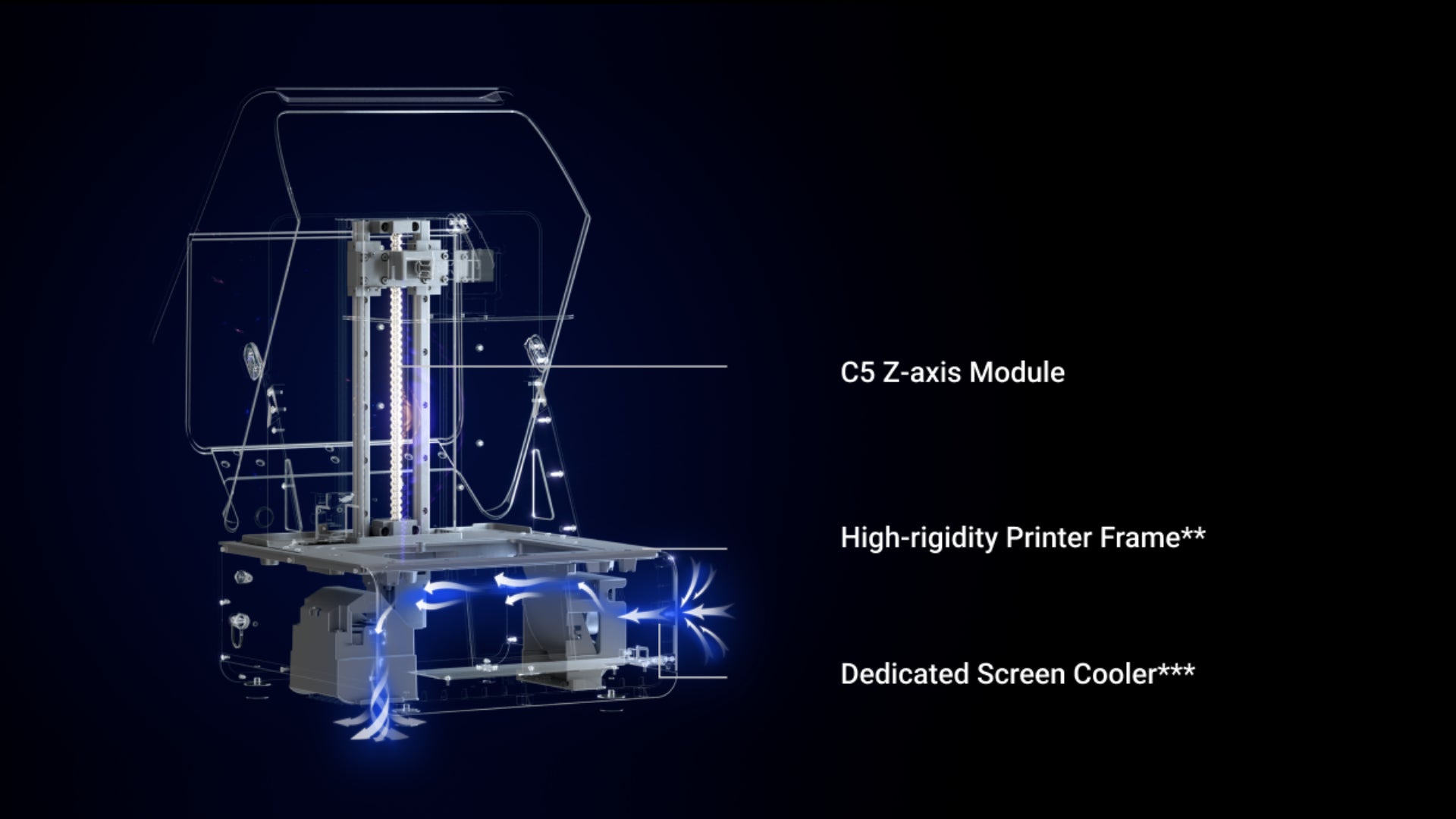

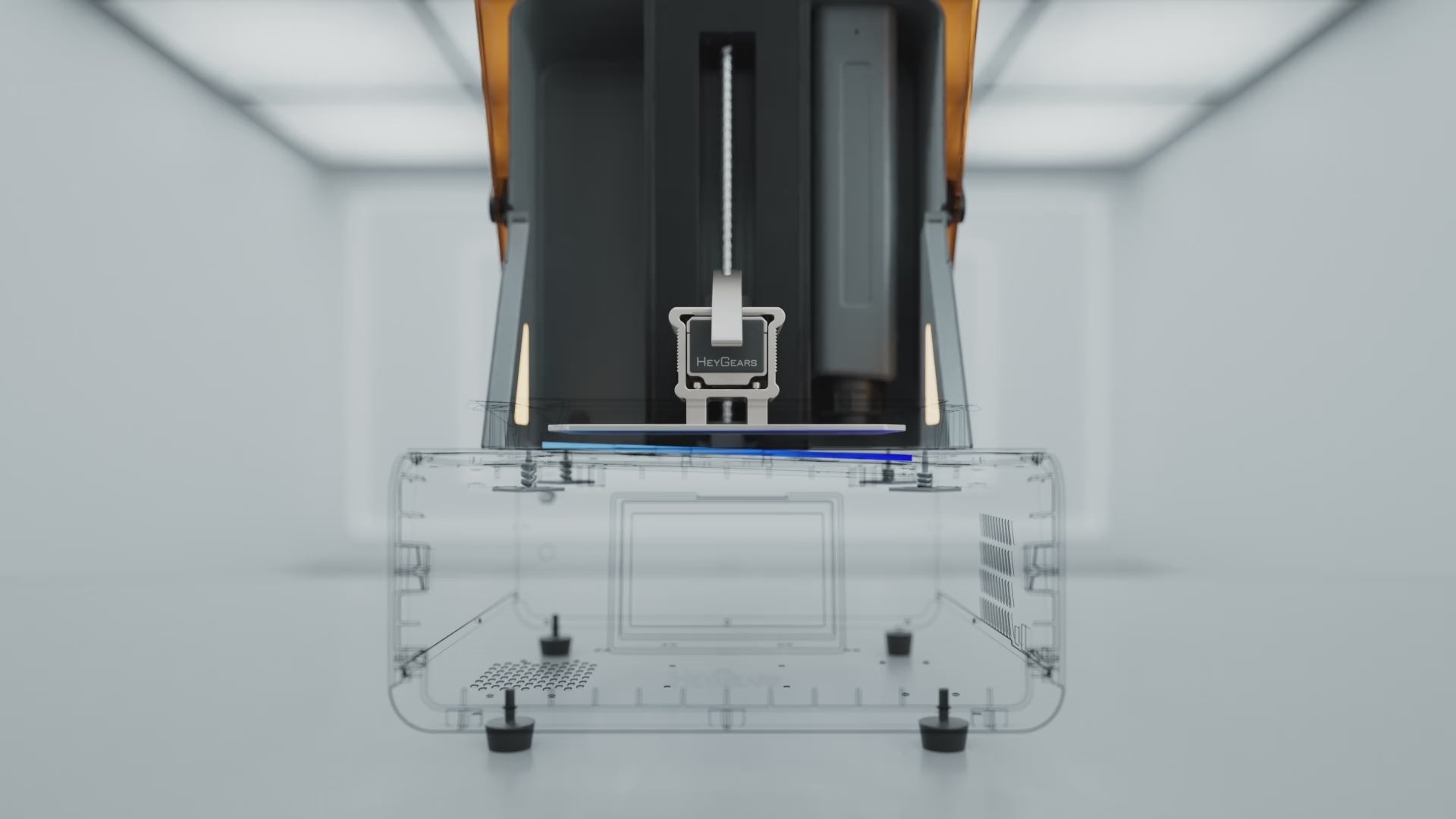

- C5 grade Z-axis module for reliable 3D printing peformance

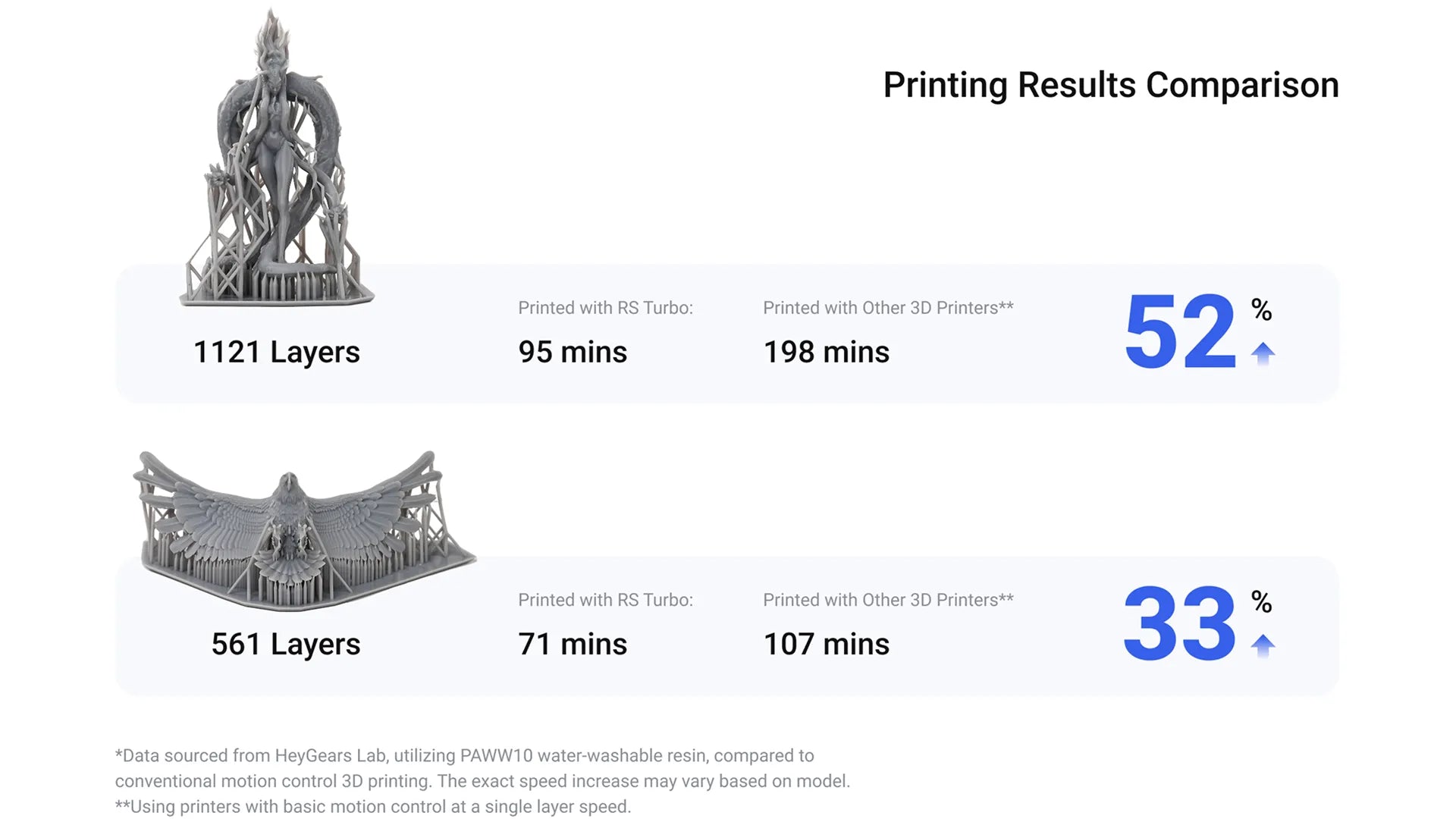

- Dynamic Motion Algorithm 3.0 for speed increases up to 33%*

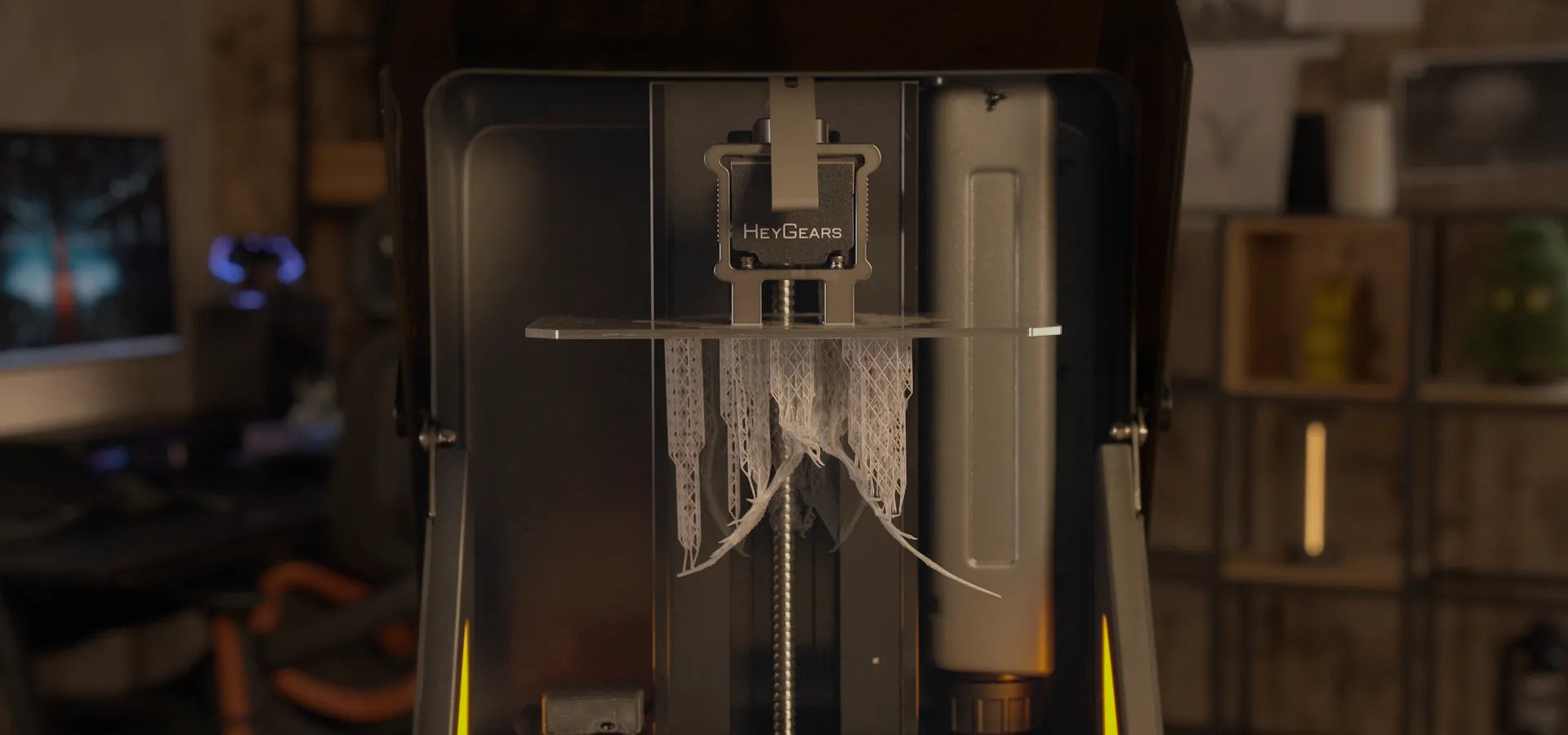

Fully Interconnected Print Strategies. No Parameter Adjustments Throughout the Whole Process.

Dynamic Motion Algorithm 3.0 for speed increases up to 33%*

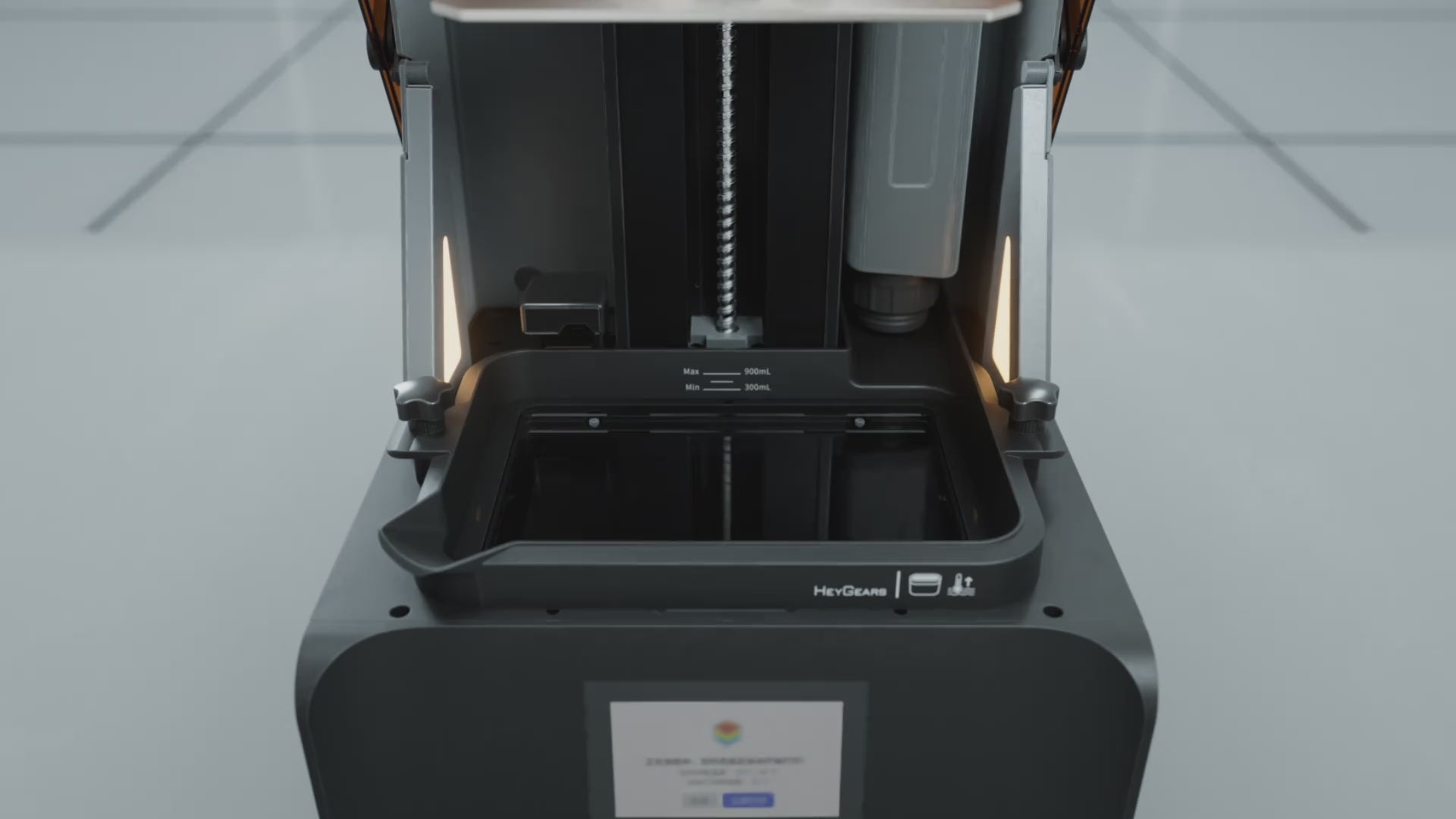

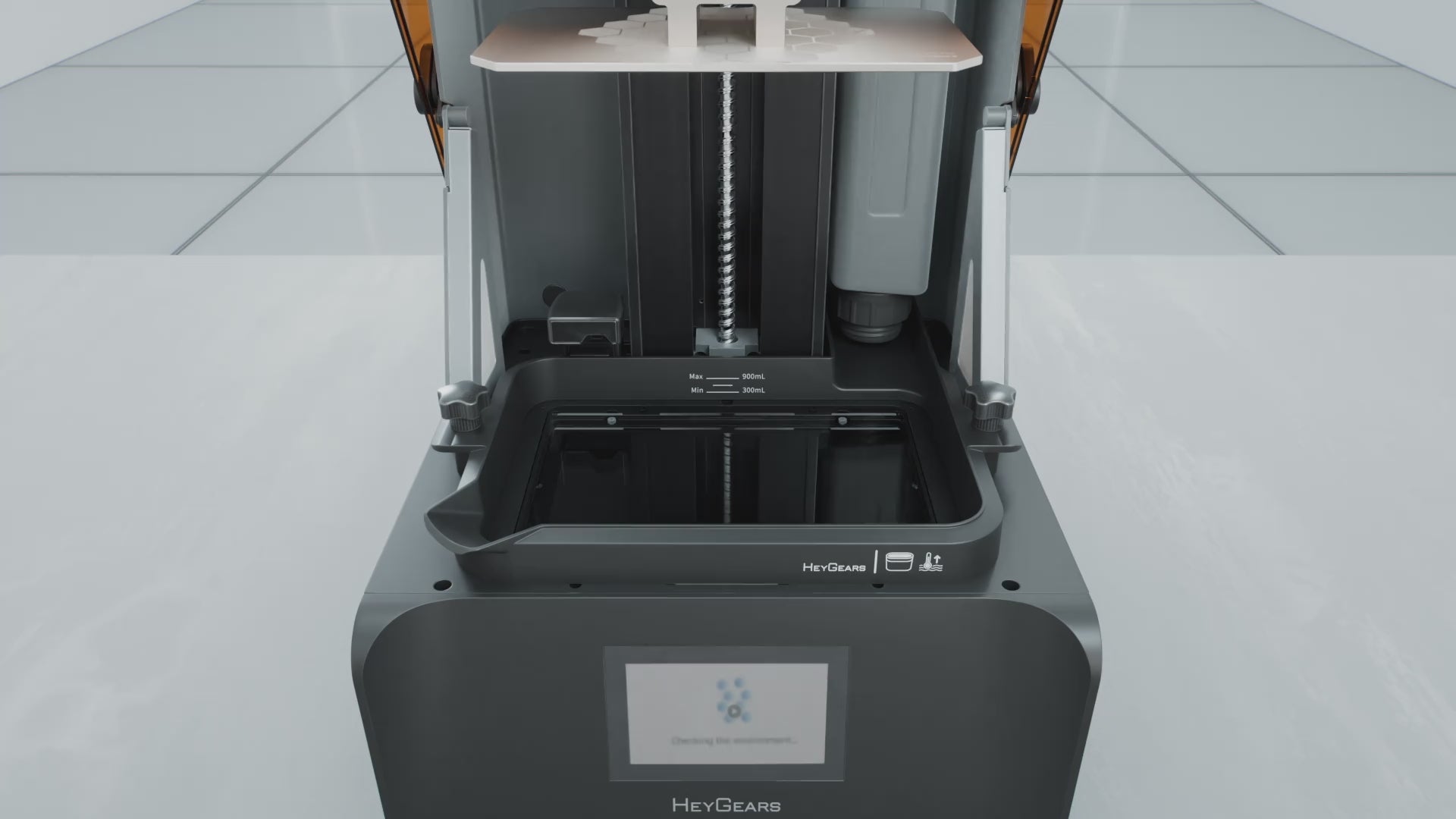

Auto Assisted Printing:

- Floating Screen Auto Leveling

- Automatic Resin Refill

- Automatic Resin Heating**

UltraCraft Wash: Minimal Contact with Resin.

UltraCraft Cure: Dual UV Wavelength Curing for Greater Material Performance. Extra Heating Function.

*Data sourced from HeyGears Lab, utilizing PAWW10 water-washable resin, compared to conventional motion control 3D printing. The exact speed increase may vary based on model.

** with RS Heated & Pulsing Release Resin Tank (purchased separately)

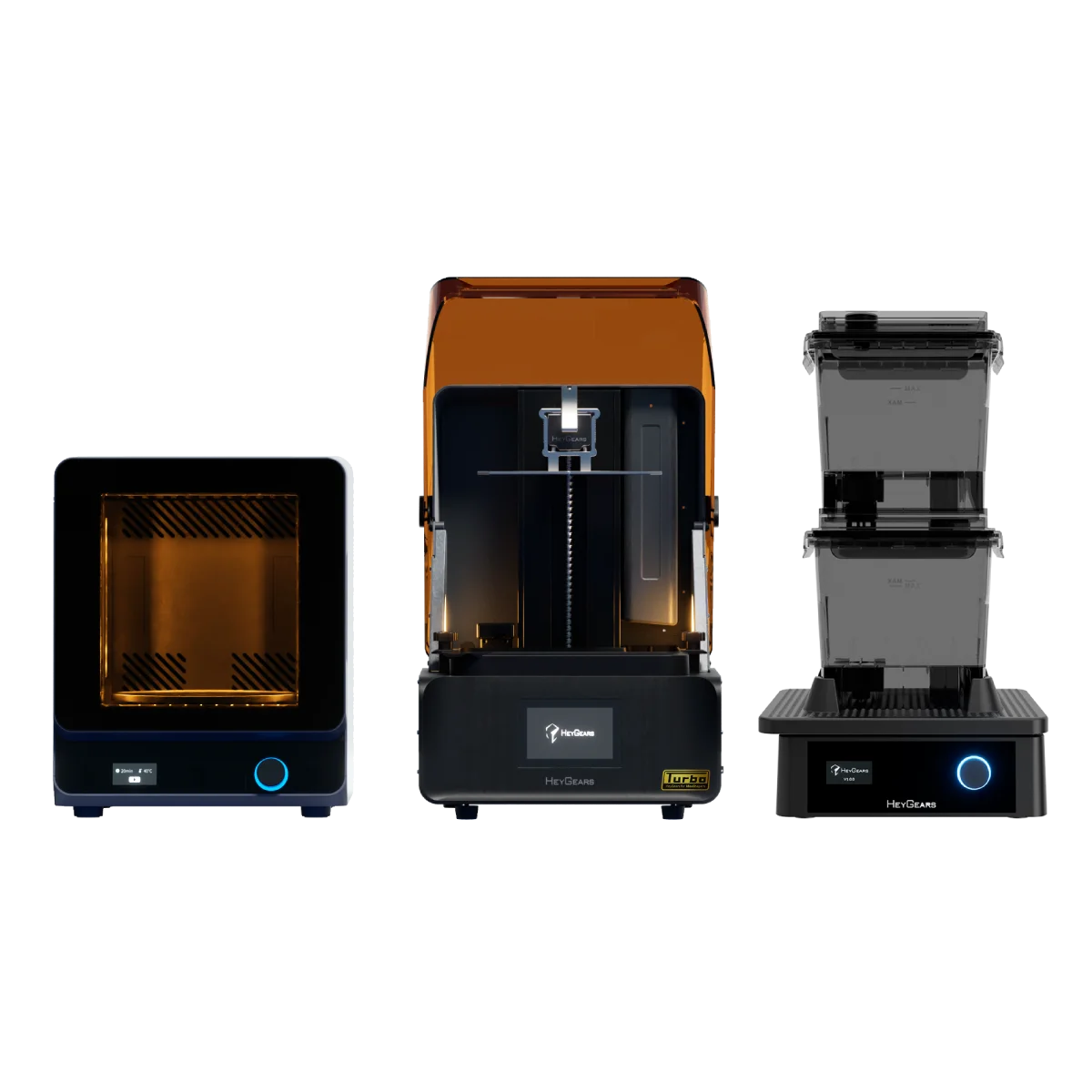

Package Includes

Reflex RS Turbo Combo:

UltraCraft Reflex RS Turbo 3D Printer x1

UltraCraft Wash x1

UltraCraft Cure x1

Reflex RS Turbo Combo with Pulsing Release Module :

UltraCraft Reflex RS Turbo 3D Printer x1

UltraCraft Wash x1

UltraCraft Cure x1

UltraCraft Pulsing Release Module x1

UltraCraft Reflex RS Turbo Heated & Pulsing Release Resin Tank x1

Pairs well with

Reflex RS Turbo Combo

We're committed to providing you with the best service. Please don't hesitate to reach out if you have any questions.

-

Shipping Information

Free shipping on orders over $399. Click here for more shipping details.

-

Customer Support

Need assistance? We are here to help!

WhatsApp:

+1 949-283-2998(US)

Mon-Fri, 9AM-5PM PSTEmail Support:

contact@heygears.com

Technical Support:

customersupport@heygears.com

-

Get Started

Getting Started with Your HeyGears 3D Printer

-

FAQ’s

Please read our FAQs page to find out more.

Hear It From Our Users

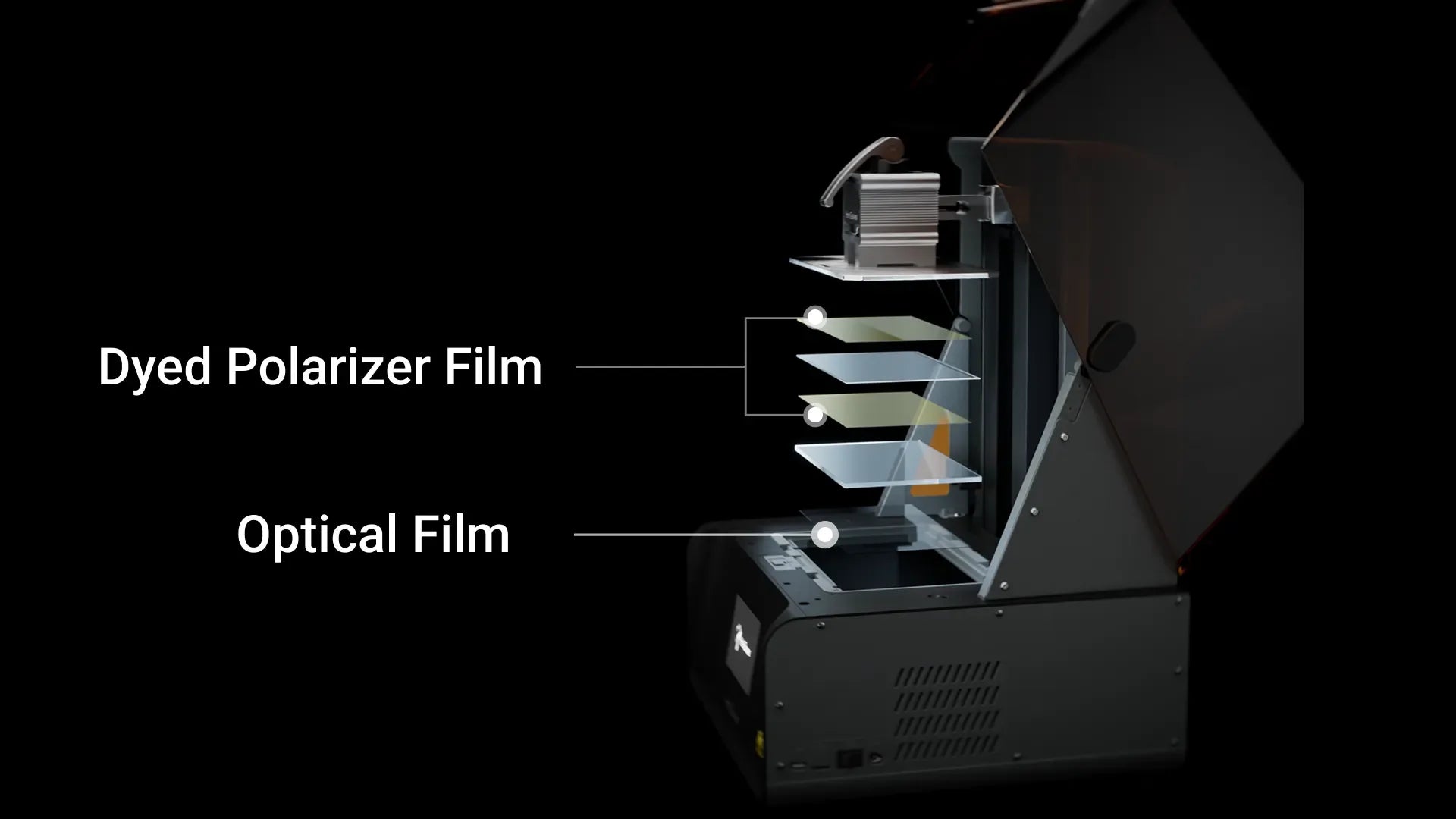

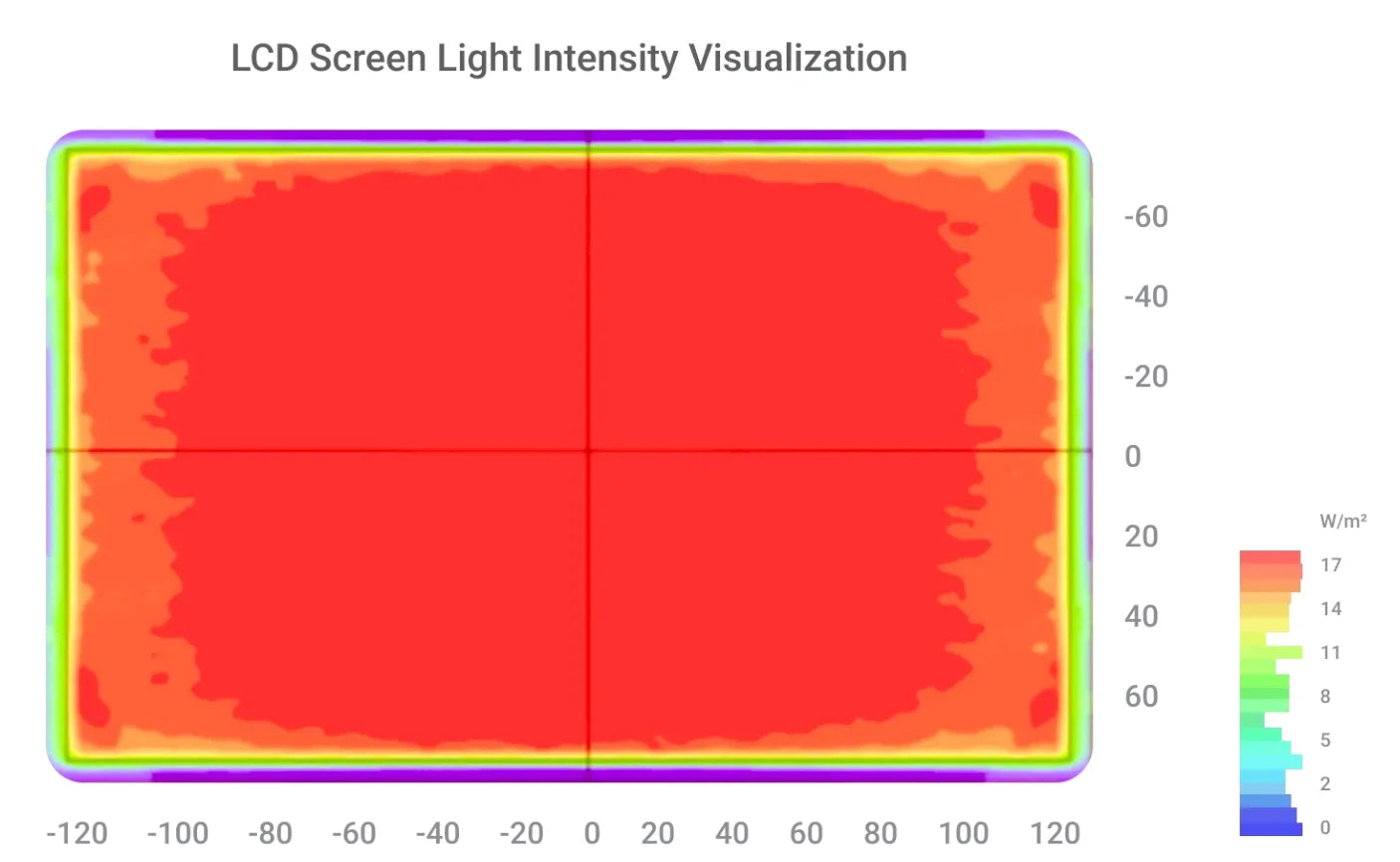

Optimized Amber Screen

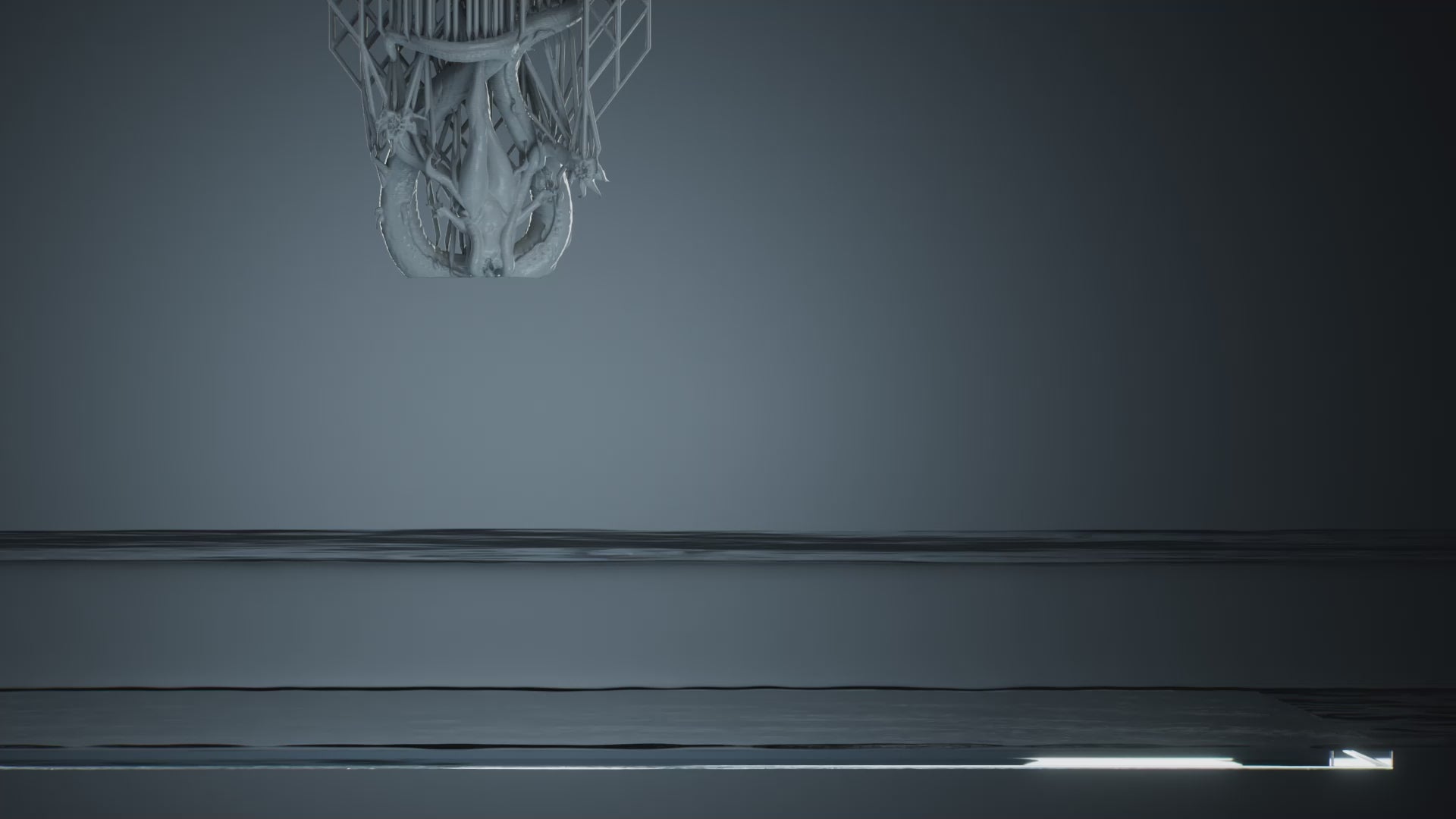

Stunning Details with Fast Speed

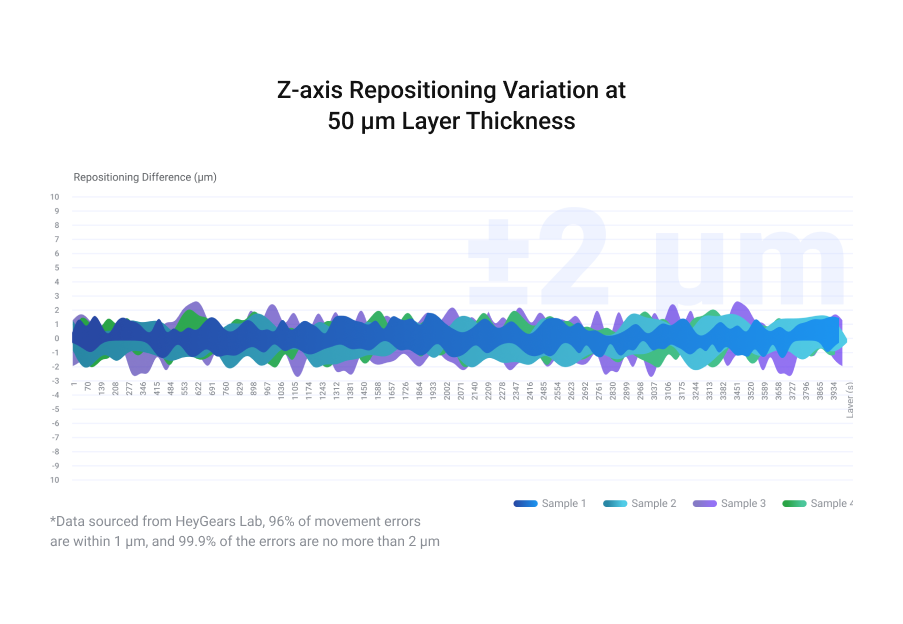

Reliable C5 grade Z-axis Module

High repeat positioning accuracy ensures layer positioning errors are no more than 2 μm*. Tested with a 50 kg load across ten thousand runs.

Adaptive Z-axis Compensation

Dynamic Motion Algorithm 3.0, 33% Increase in Print Speed*

*Data sourced from HeyGears Lab, utilizing PAWW10 water-washable resin, compared to conventional motion control 3D printing. The exact speed increase may vary based on model.

A Complete Production System

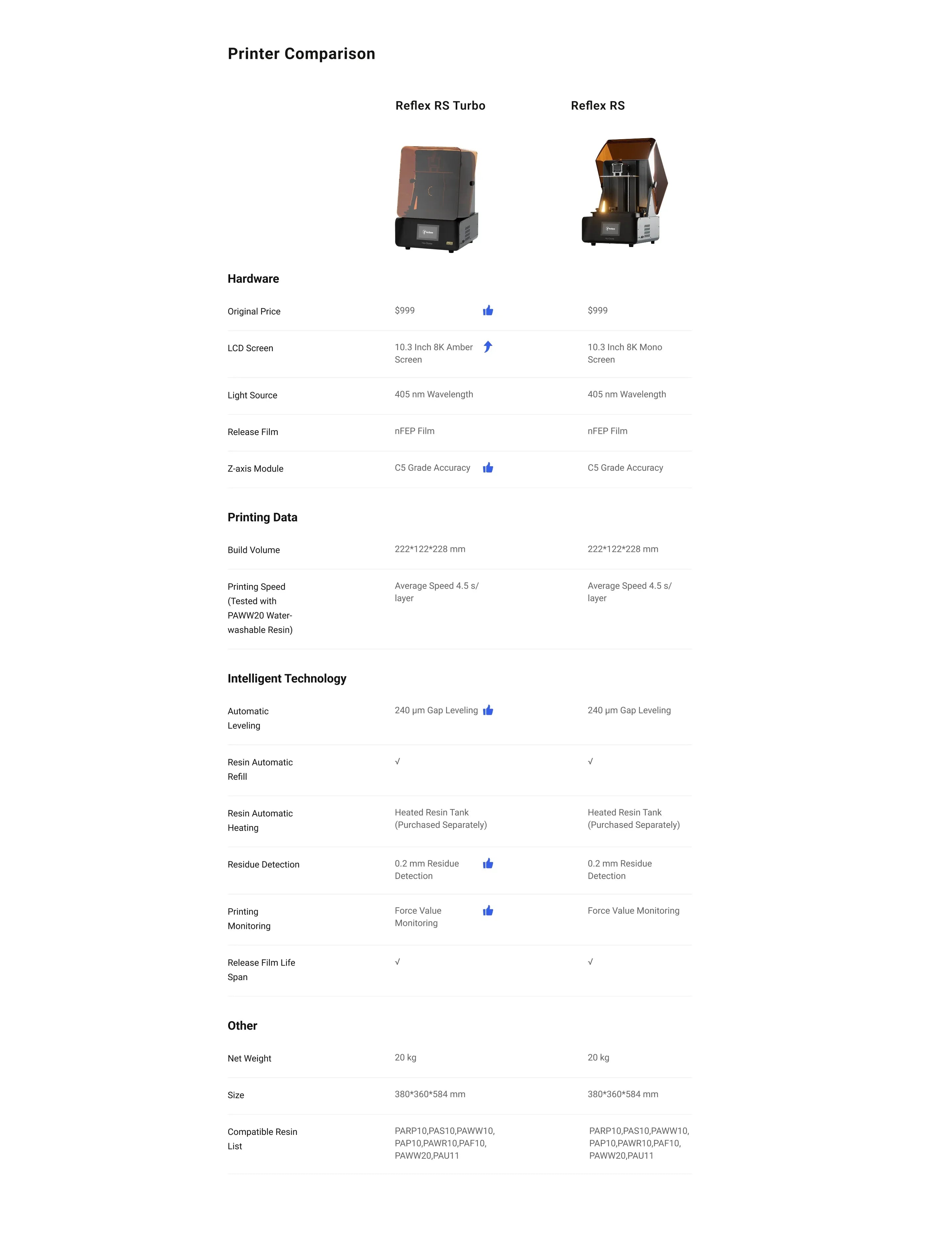

Specifications

3D Printing Technology:

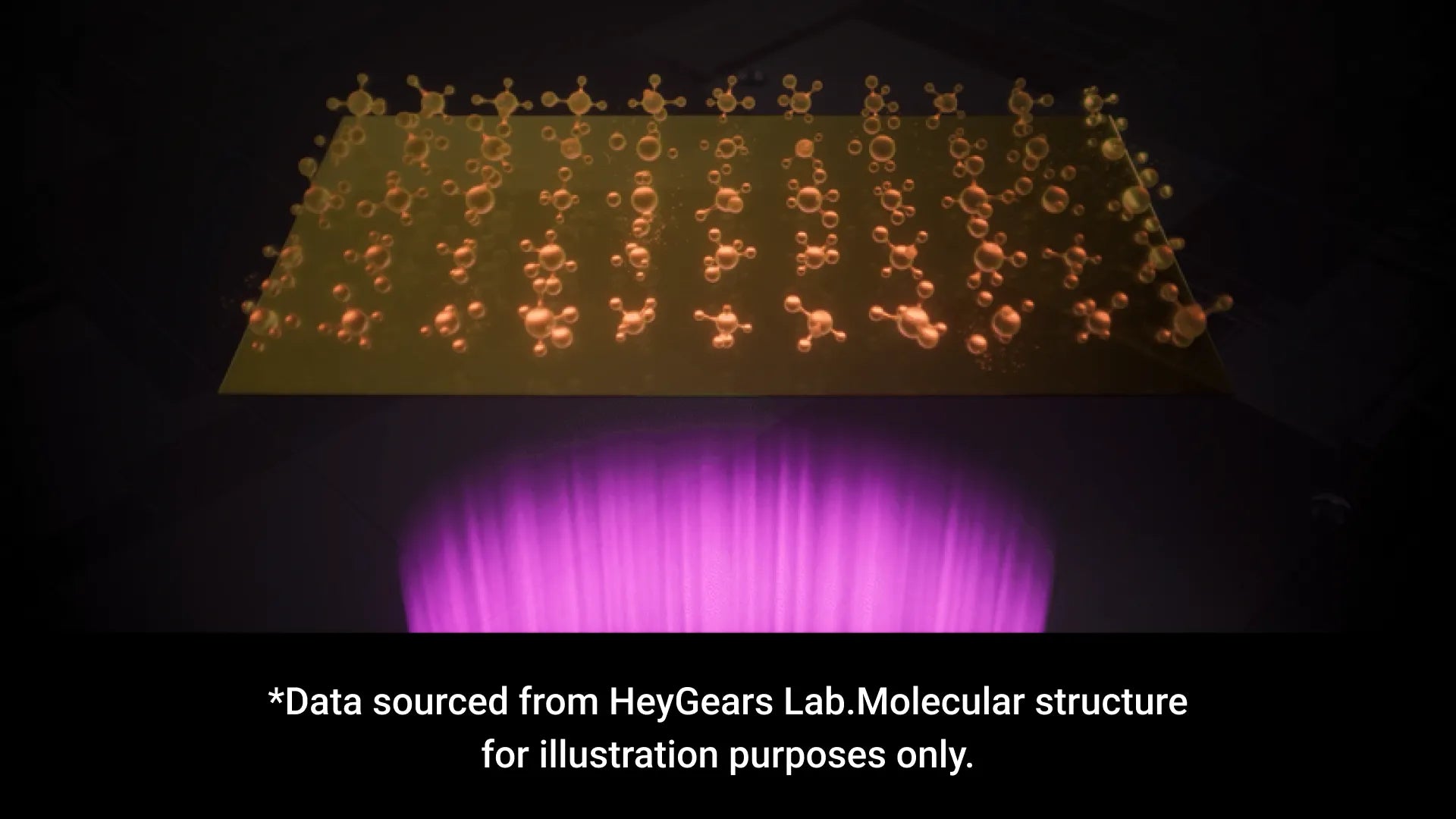

LCD (MSLA)

Screen:

10.3-inch 8K Amber Screen

Optical Wavelength:

405 nm

Z-axis Module:

C5 Grade Accuracy

Build Volume:

222*122*228 mm

XY Native Pixel:

29.7 μm

Accuracy:

±15 μm

Layer Thickness:

30-100 μm

Weight:

20 kg

Rated Power:

180 W

Voltage:

100-240 V~50/60 Hz

Size:

380*360*584 mm

Connectivity:

USB/WIFI

Language:

English, Simplified Chinese, Japanese

Compatible Resin

PARP10、PAS10、PAWW10、PAP10、PAWR10、PAF10、PAWW20

Included in the Box

Printer

Power Cord

Part Removal Tool

Resin Tank

Build Platform

Allen Wrench

Scraper

FAQs

Please read our FAQs page to find out more.

What is the optimal printing speed for a 3D printer?

The optimal printing speed depends on the model complexity, resin type, and printer specifications. The HeyGears Reflex RS Turbo, with its Dynamic Motion Algorithm 3.0, can increase print speed by up to 33%, delivering fast yet reliable prints without sacrificing detail.

Why is there nothing displayed in the resin 3D printer?

If your resin printer displays nothing, it could be due to a screen issue, loose cable connection, or incorrect slicer settings. On the Reflex RS Turbo, the enhanced amber screen and stable Z-axis system help reduce such failures, but regular checks of screen condition and connections are still recommended.

How long can a resin 3D print be preserved?

Properly post-cured and stored resin prints can last several years. To preserve longevity, keep them out of direct sunlight, avoid high humidity, and store in a cool, dry place. The Reflex RS Turbo's high-precision curing process helps prints resist deformation over time.

What should I do if the resin on my 3D print slowly falls off?

Falling resin typically results from incomplete curing or poor adhesion. Ensure proper post-curing under UV light, and always use the recommended exposure settings in your slicer. The RS Turbo’s high-contrast 566:1 screen minimizes underexposure, improving print integrity.

How does HeyGears Reflex RS Turbo resin 3D printing work?

The Reflex RS Turbo uses LCD-based resin printing technology. UV light passes through a high-contrast amber screen, curing resin layer by layer. With a C5-grade Z-axis module and enhanced motion control, it delivers smooth, high-precision prints consistently.

How do I color a resin 3D print?

You can color resin prints in several ways:Paint them using acrylic paints after cleaning and curing.Add pigments to the resin before printing.Use pre-colored resins compatible with your printer.Ensure the surface is clean and dry before applying any paint or coating.